Hand-held machine tool

A hand-held machine tool, work area technology, applied in manual planing, manufacturing tools, hand-operated planing equipment, etc., can solve problems such as poor mechanical stability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

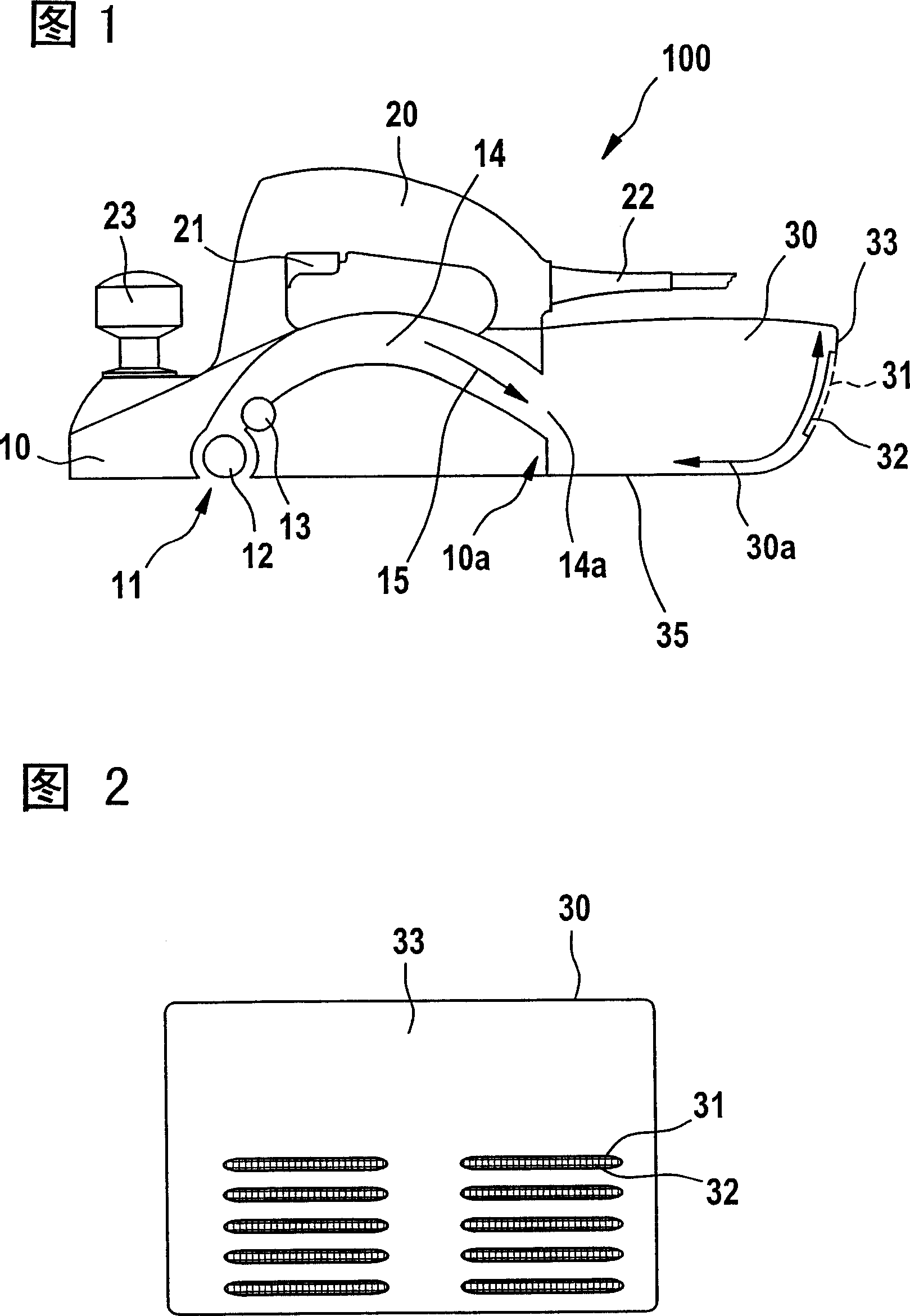

[0020] FIG. 1 schematically shows a hand planer 100 in longitudinal section. The hand planer comprises a housing 10 with a handle 20 , a power cable 22 , a switch 21 for switching the hand planer 100 on and off and a rotary switch 23 for adjusting the cutting depth.

[0021] A guide channel 14 is provided in the housing 10 , in which swarf and / or abrasive particles are guided away from the working area of the hand planer 100 . The guide channel 14 extends longitudinally from the working area 11 through the hand planer 100 and is open to the rear, whereby an open end 14 a of the guide channel for ejecting chips is arranged in the rear region of the housing 10 10a. The guide channel 14 is arched across an electric motor (not shown) arranged transversely to the guide channel 14 .

[0022] Arranged in the working area 11 is a roller-shaped knife shaft 12 for cutting chips, in particular of woody material, which is driven via a drive belt by the electric motor of the hand-held ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com