Method and apparatus for lubricating cylinder surfaces in large diesel engines

A lubricating device and lubricating oil technology, which is applied in the field of lubricating systems, can solve problems such as high external injection pressure, and achieve the effect of a simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

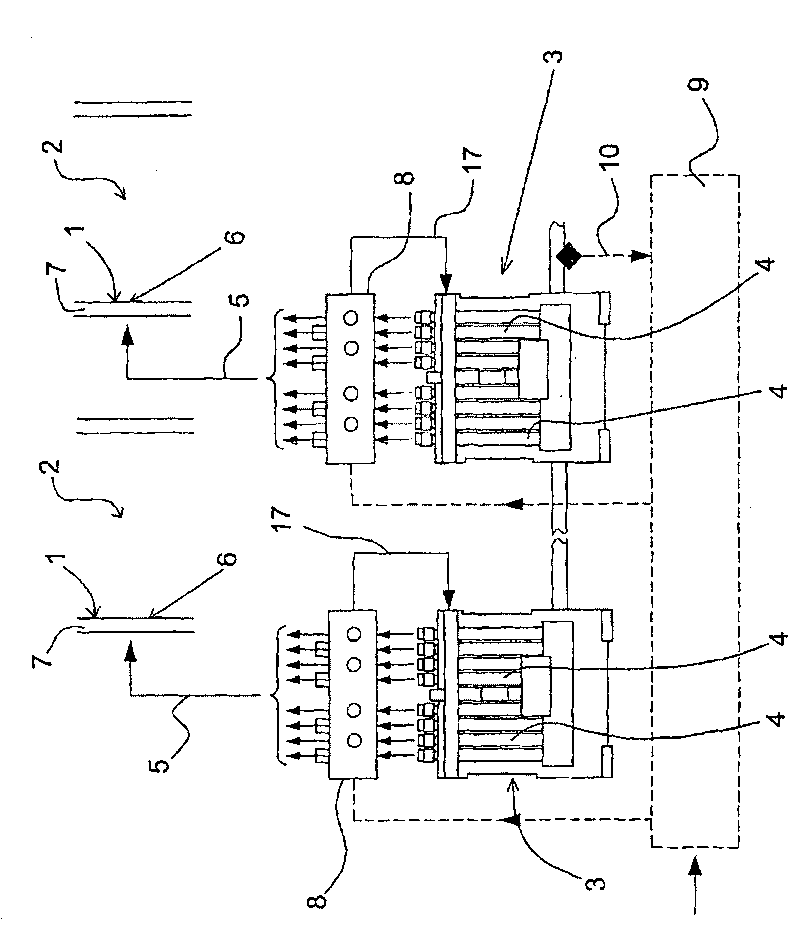

[0052] figure 1 Shown is an apparatus for lubricating the cylinder inner surface 1 of a cylinder 2 of a large diesel engine. The apparatus shown comprises two lubricating devices 3 each having a series of piston pumps indicated at 4 . Via connecting pipes 5 (only one is shown for each lubricating device), each piston pump is connected to a lubrication point 6 provided in the cylinder wall 7 for lubricating the cylinder inner surface 1 of the cylinder wall. The device also includes a flow regulator 8, which will refer to figure 2 Describe in detail.

[0053] Furthermore, the device comprises an electronic control unit 9 connected to the flow regulator 8 and the lubricating device 3 . As indicated at 10 , the flow regulator may receive an indication signal from the lubricating device 3 .

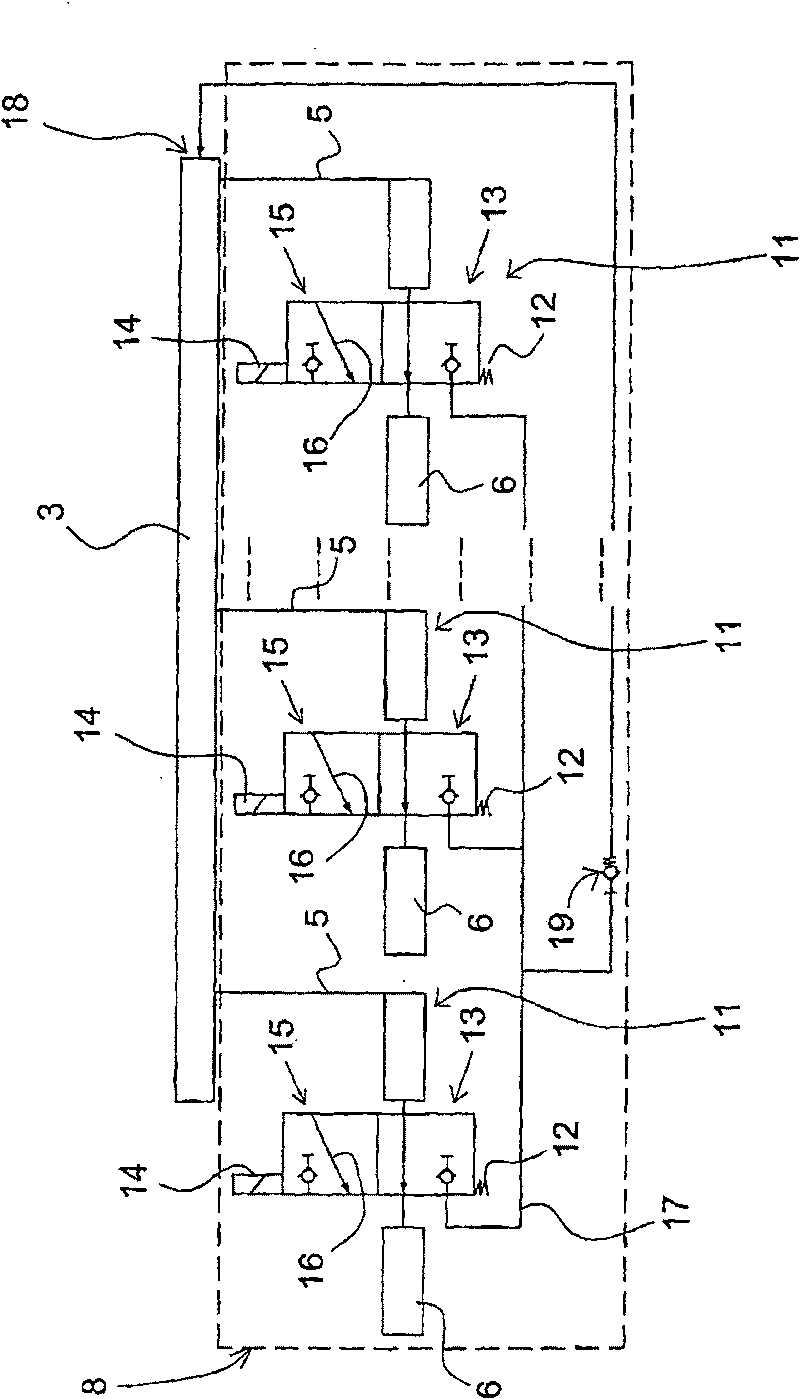

[0054] figure 2 is a schematic diagram of the flow regulator 8 . figure 2 Three lubrication points 6 and a lubrication device 3 are shown. This state therefore shows that there are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com