Semiconductor device and its manufacturing method

A technology of semiconductors and devices, which is applied in the field of semiconductor devices and their manufacturing, can solve problems such as deterioration of component characteristics and high drain region resistance, and achieve the effects of improving component performance, reducing lead inductance, and reducing power supply noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

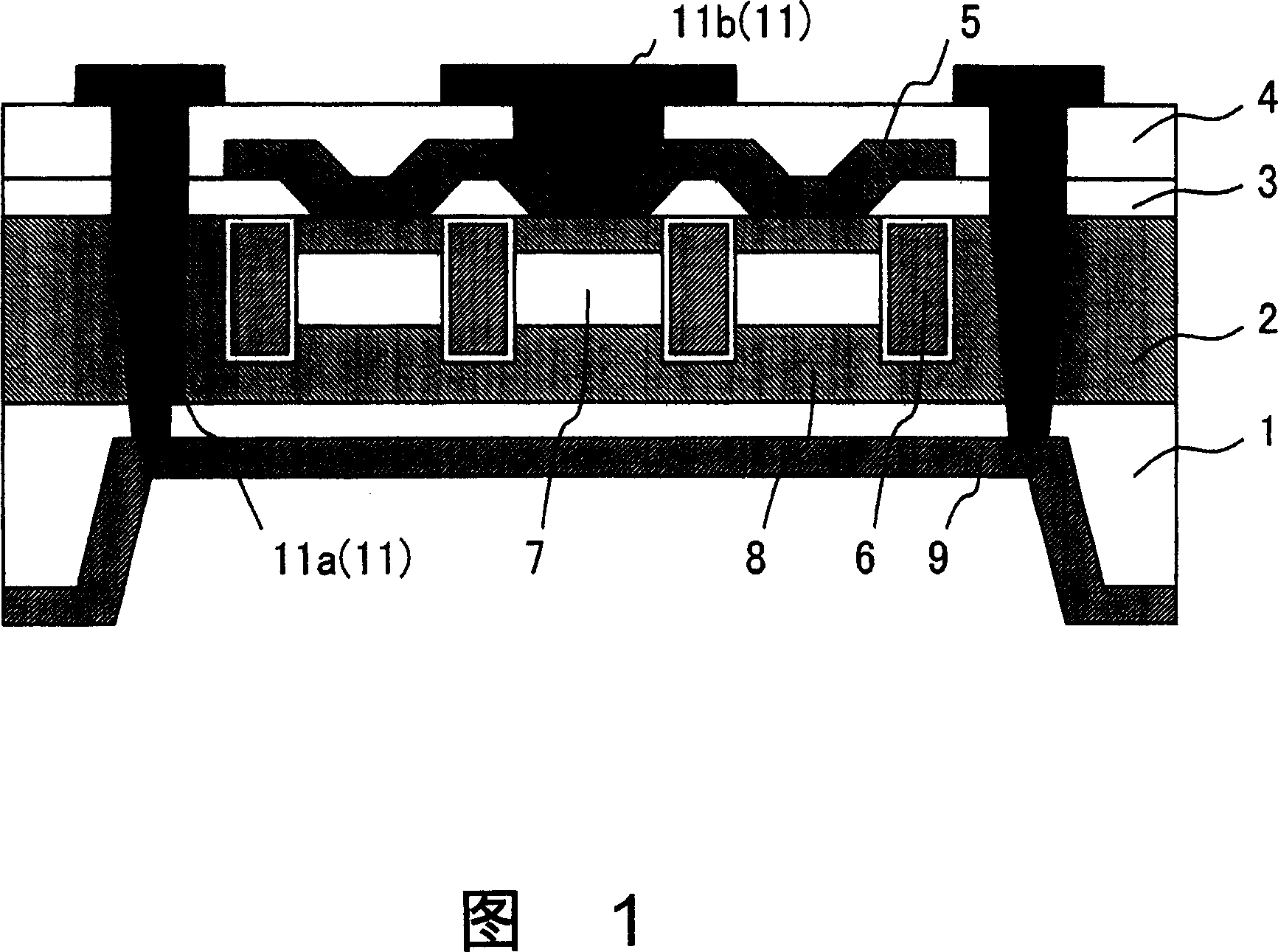

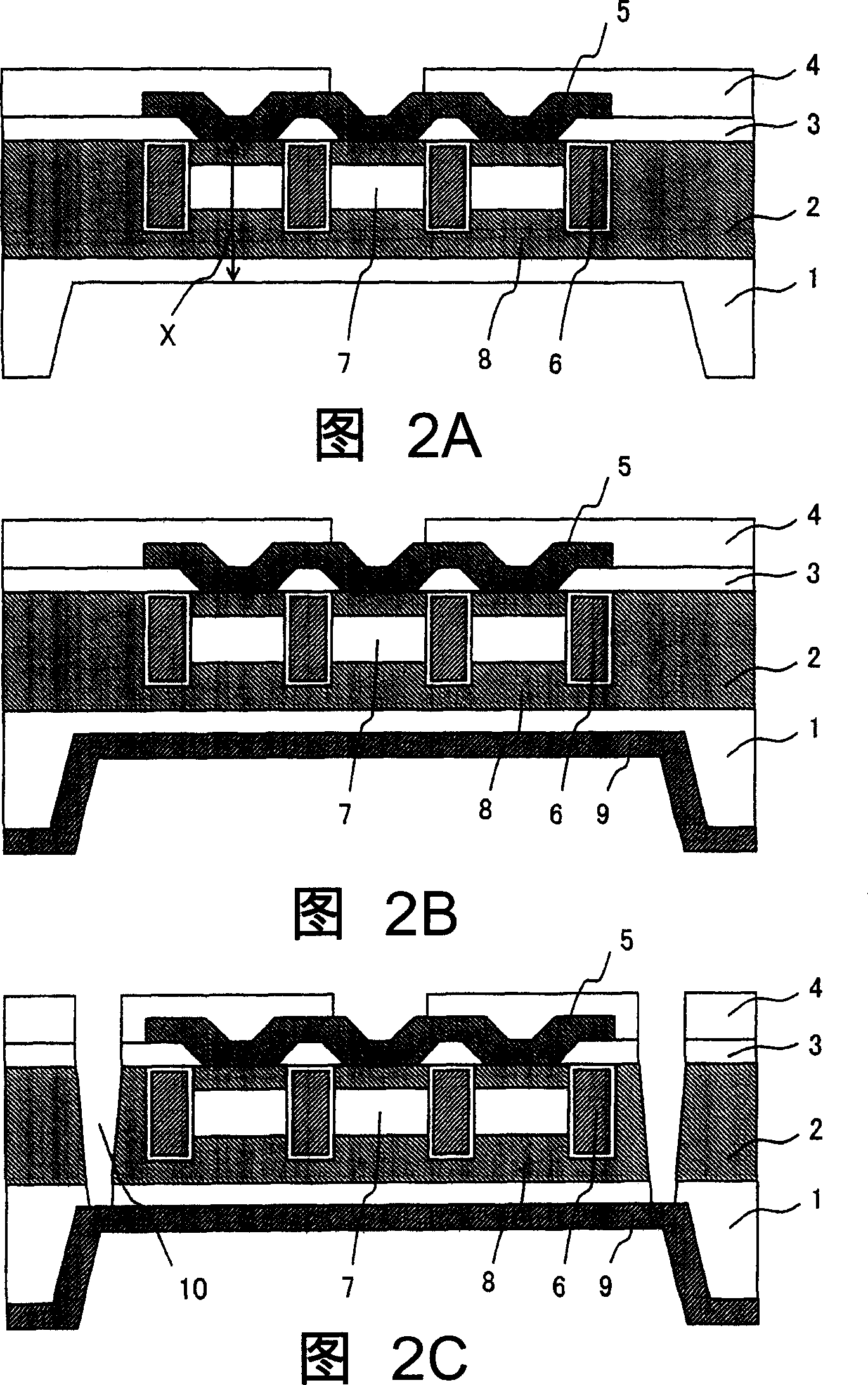

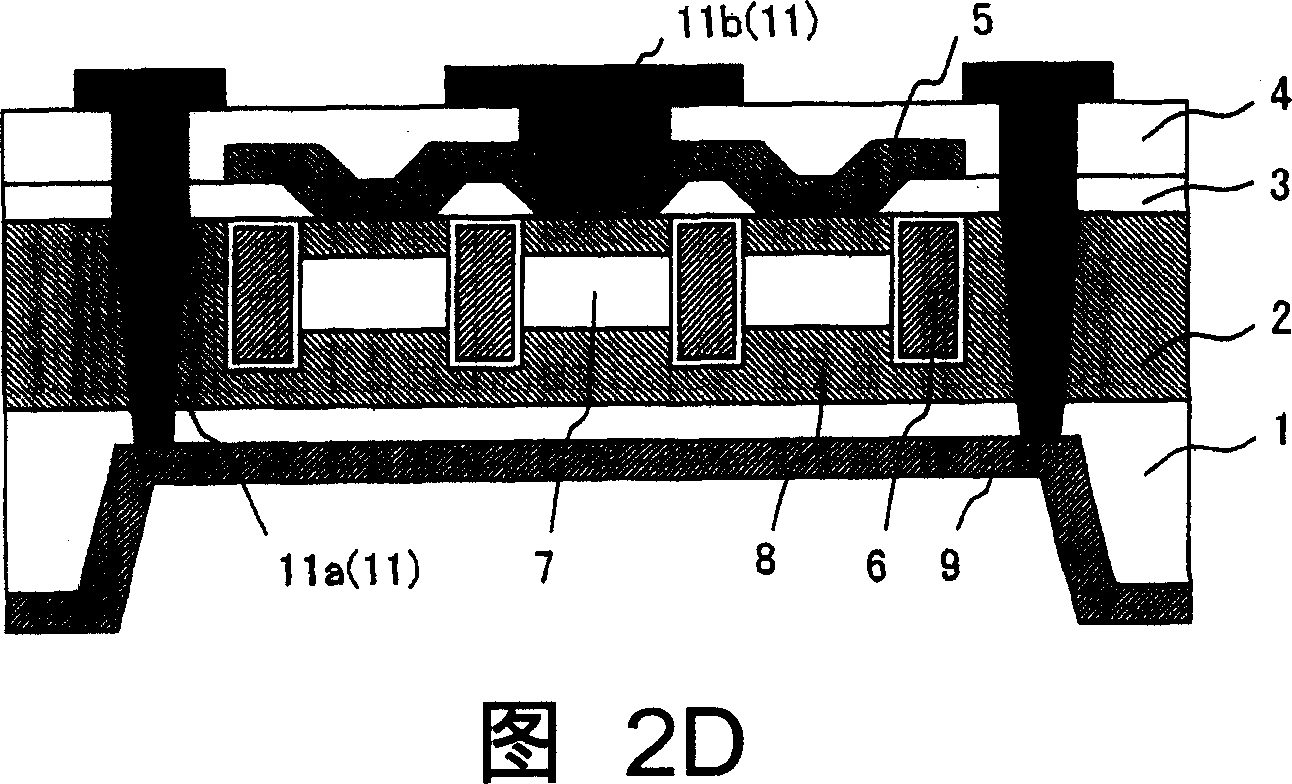

[0023] A device of the present invention and a method of the present invention according to a first embodiment will be described with reference to FIG. 1 and FIGS. 2A to 2D. Here, FIG. 1 is a schematic cross-sectional view showing a schematic configuration of a device of the present invention according to this embodiment.

[0024] The transistor employed in this embodiment is a trench type power MOSFET, and at least one first electrode 11 b provided on the front surface of the silicon substrate 1 is electrically connected to the source electrode of the transistor through a metal lead 5 . Further, through electrode 11 a is electrically connected to the drain electrode of the transistor through a second electrode (metal layer 9 ) provided on the rear surface of silicon substrate 1 . Further, the via electrode 11a is electrically connected to the second electrode (metal layer 9) through a via hole penetrating the semiconductor chip from its front surface to its rear surface. A p...

no. 2 example

[0031] The method of the present invention according to the second embodiment will be described with reference to FIGS. 3A to 3D. In this embodiment, description will be made using a trench type power MOSFET as an example similar to the first embodiment.

[0032] First, a trench type power MOSFET is formed by a conventional process similar to that of the first embodiment. Then, according to this embodiment, as shown in FIG. 3A, the thickness of the silicon substrate 1 is reduced to about 100 [mu]m by grinding the back surface.

[0033]Then, as shown in FIG. 3B, metal layer 9 is formed on the rear surface of silicon substrate 1 by sputtering. In this embodiment, although the material of metal layer 9 is not particularly limited similarly to the first embodiment, a metal material having low resistance is employed to minimize an increase in on-resistance.

[0034] Then, as shown in FIG. 3C, a via hole 10 is formed to reach the metal layer 9 from the front surface of the silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com