Ship ballast water treating process and apparatus

A technology for ship ballast water and a treatment method, which is applied in the field of ship ballast water treatment equipment and can solve the problems of high cost and low treatment method efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

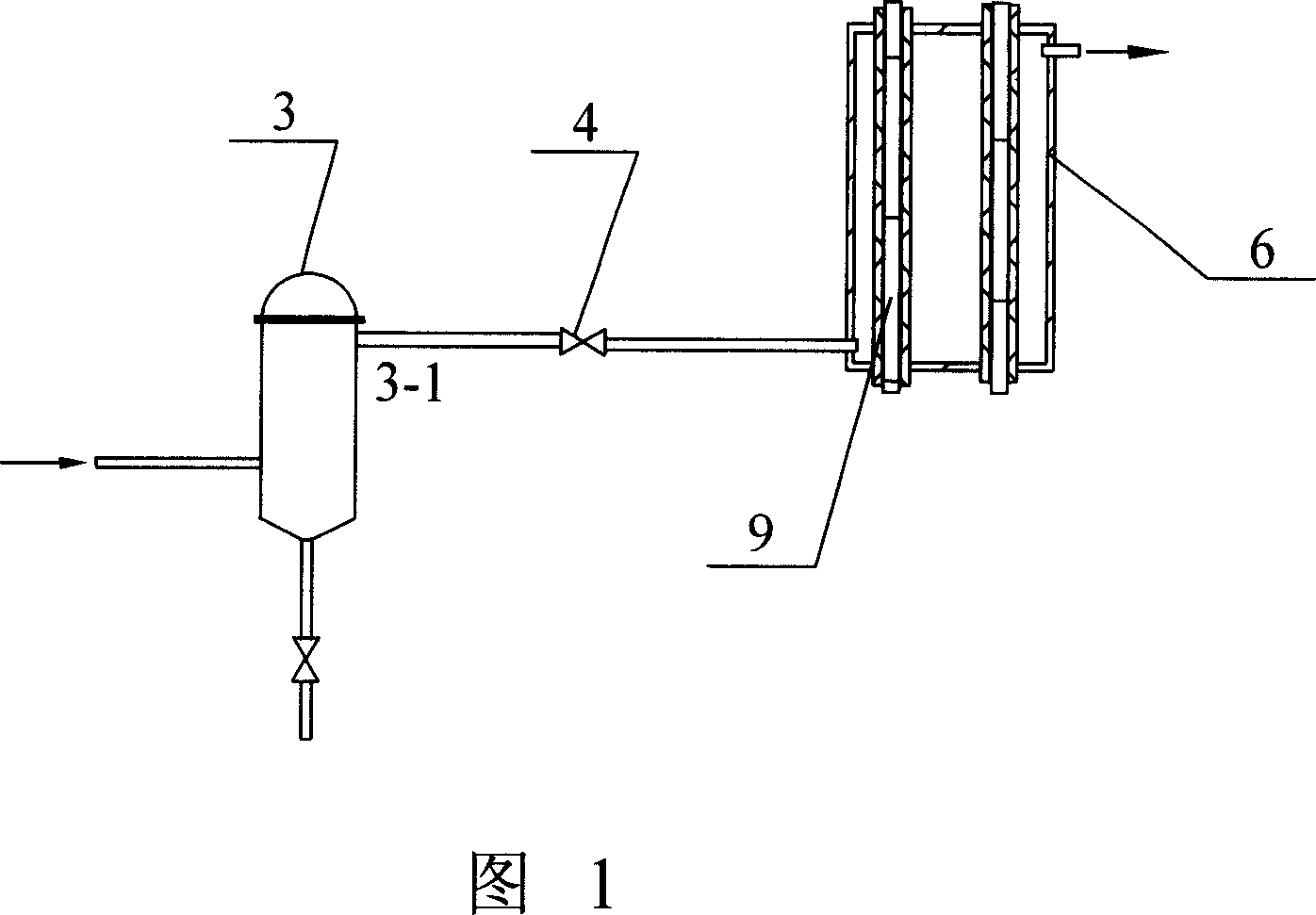

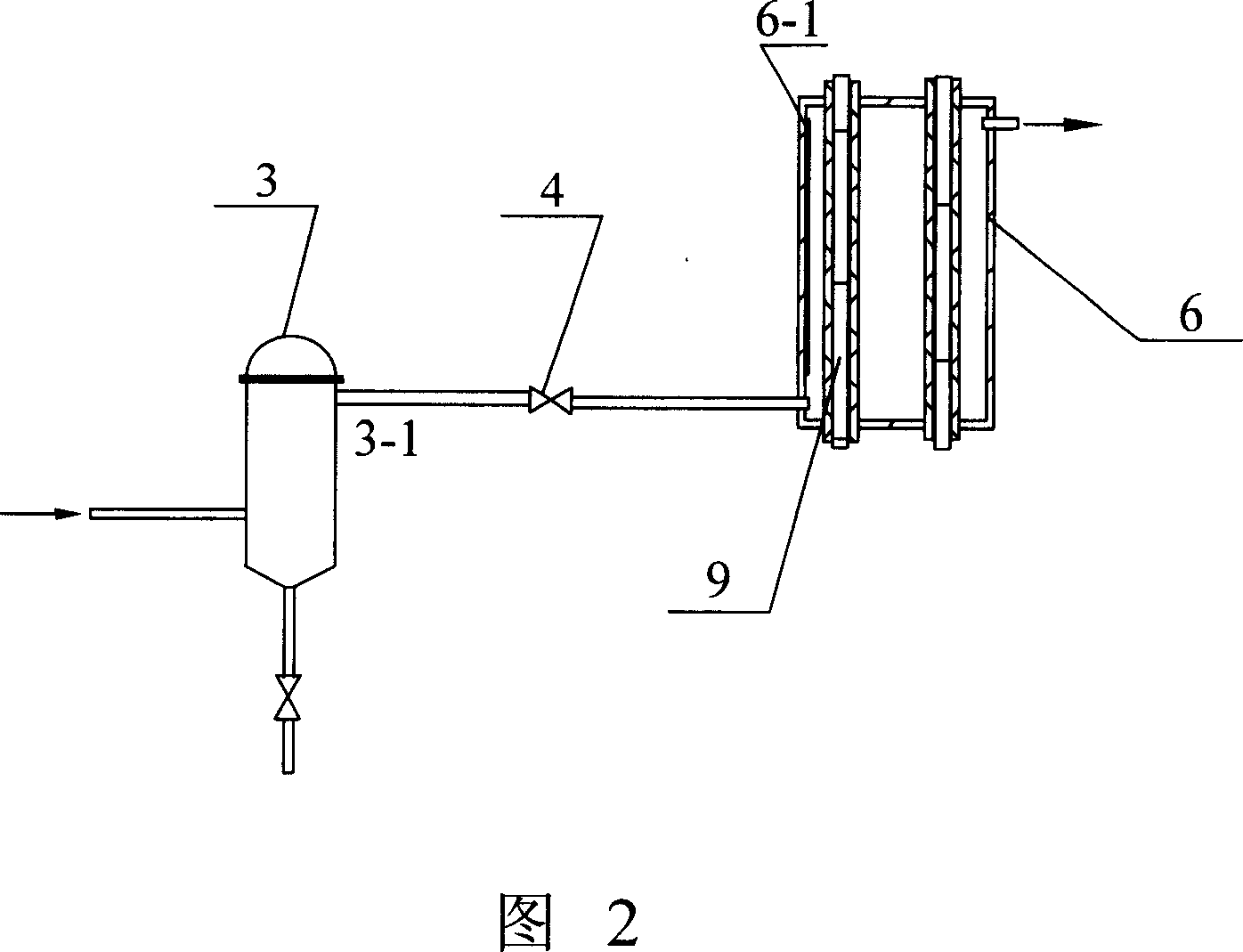

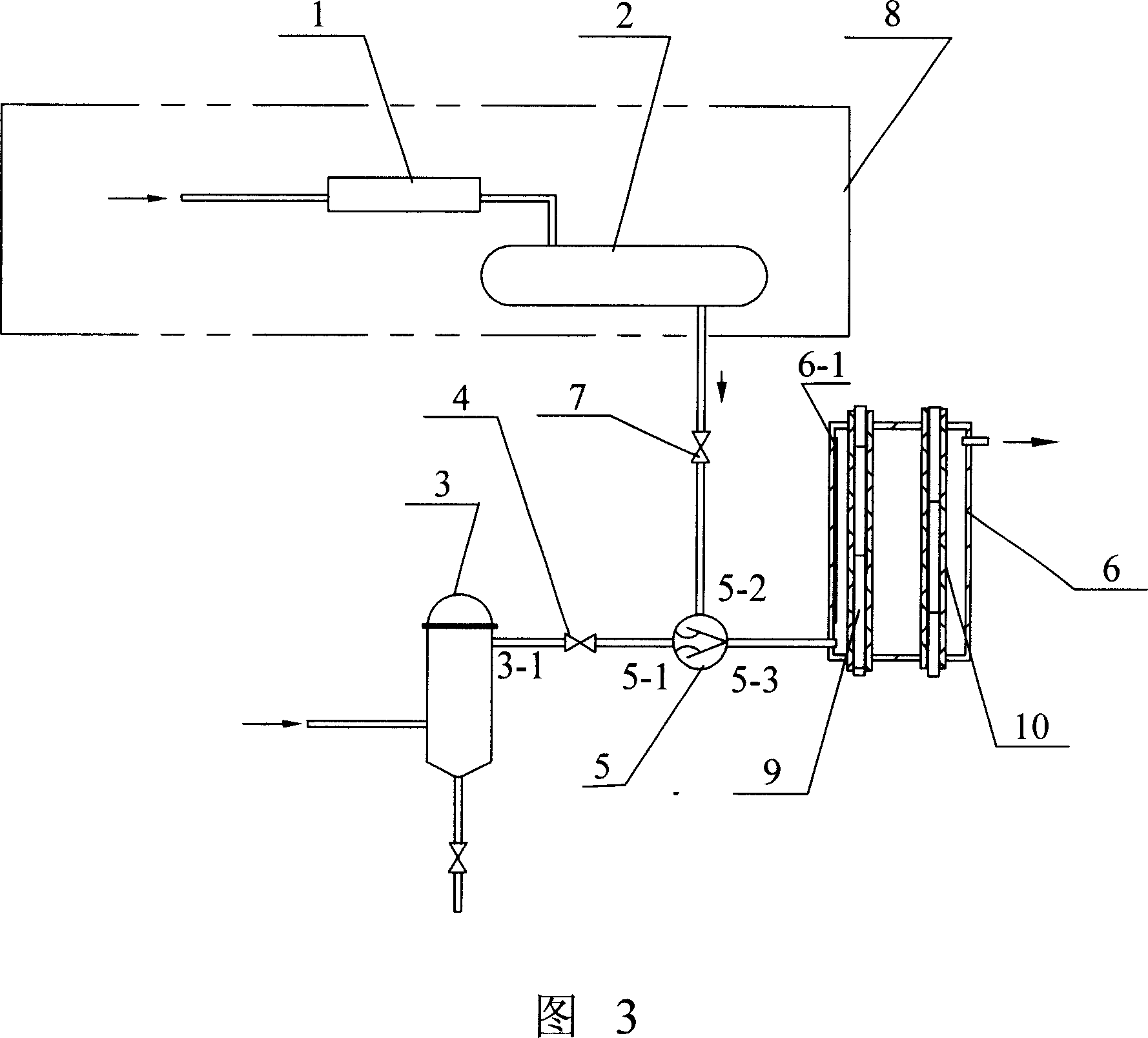

[0009] Specific embodiment one: the treatment method of ship's ballast water in this embodiment is realized through the following steps successively: a, ship's ballast water is filtered, removes the sundry greater than 50 microns; Can use filter to filter out sundry when filtering things. c. Irradiate the ship's ballast water with ultraviolet light to remove bacteria, single-celled algae, and protozoa in the ballast water.

specific Embodiment approach 2

[0010] Embodiment 2: The difference between this embodiment and Embodiment 1 is: this embodiment also includes step b between step a and step c, mixing ozone into the ship's ballast water. Other steps are the same as those in Embodiment 1.

[0011] Under ultraviolet light irradiation, ozone undergoes the following reactions to generate hydroxyl radicals:

[0012]

[0013]

[0014] Or proceed as follows:

[0015]

[0016]

[0017] The standard redox potential of HO is as high as 2.80 V, second only to F 2 2.87V, which has a higher oxidation capacity than other common oxidants, which can directly damage the DNA of microorganisms and cause the death of microorganisms.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and embodiment one is: while irradiating the ship's ballast water with ultraviolet light in step c, add TiO in the photocatalytic reactor 2 Metal doped photocatalysts. Other steps are the same as those in Embodiment 1.

[0019] TiO 2 Holes are generated under UV radiation (h + ) and electrons (e - ), and then produce hydroxyl radicals:

[0020]

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com