Screw extruding welding method

A welding method and screw extrusion technology, which is applied in the field of screw extrusion welding, can solve the problems of many weld seams, slow work efficiency, and unsatisfactory welding strength, and achieve the effect of high welding strength and saving work efficiency

Inactive Publication Date: 2007-06-06

JIANGSU SERO ANTICORROSION EQUIP

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In the past, hot air welding was used for plastic pipe welding. The hot air was used to heat the welding rod and the welding surface to a molten state, and a certain force was applied to weld the surface. The disadvantage is that the size of the welding rod is basically fixed, so the larger the welding surface, the more welds, and the work efficiency Slow, the welding strength is not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] Injection material temperature ℃

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

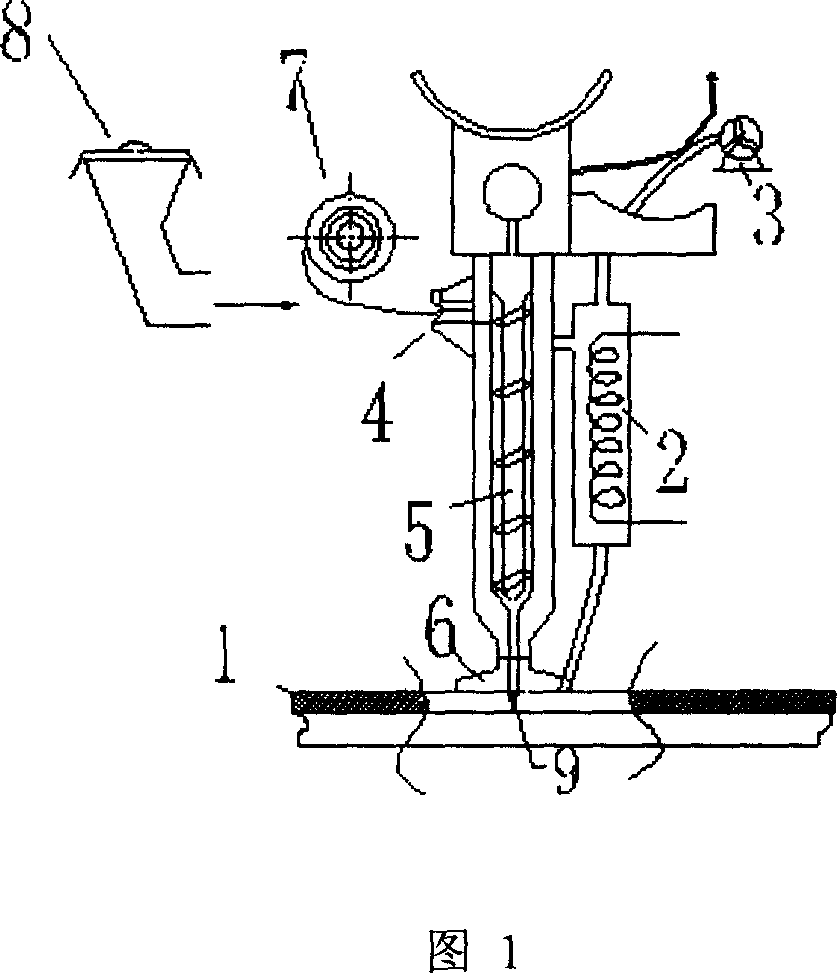

The present invention belongs to the field of welding mode, and is especially one kind of screw extruding welding method. The extrusion welding apparatus includes one small ejecting machine and one motor driven softening mechanism, which heats the welding machine to the welding temperature before starting a blower to heat air. The welding wire fed to the ejecting mechanism is plasticized and extruded before being distributed and pressed to the welded surface with one welding seat, and the welding machine moving forward smelts the welded surface and the extruded material simultaneously to form tightly combining weld seam without wave. The excessive ejected material in the edges of the weld seam is then eliminated with some special tool and the weld seam is finished. The present invention has the advantages of weld seat selection based on the welded surface size, high welding strength, high efficiency, etc.

Description

technical field [0001] The invention belongs to a welding method, in particular to a screw extrusion welding method. Background technique [0002] In the past, hot air welding was used for plastic pipe welding. The hot air was used to heat the welding rod and the welding surface to a molten state, and a certain force was applied to weld the surface. The disadvantage is that the size of the welding rod is basically fixed, so the larger the welding surface, the more welds, and the work efficiency Slow, the welding strength is not ideal enough. 200610002534.3, "Extrusion machine, especially extrusion welding device", which is a hand-held extrusion welding device, in order to discharge the gas in the partially plasticized plastic to be extruded in the extruder, it proposed An unthreaded segment is set between the two threaded segments of the exit screw. Contents of the invention [0003] The purpose of the present invention is to provide a screw extrusion welding method. The...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C65/40B29C47/36B29C48/395

CPCB29C47/38B29C48/395

Inventor 姚迎春张跃生李慧张明开

Owner JIANGSU SERO ANTICORROSION EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com