Process of preparing bismuth telluride-base thermoelectric material

A thermoelectric material, bismuth telluride-based technology, which is applied in the manufacture/processing of thermoelectric devices, the improvement of process efficiency, and the improvement of energy efficiency, etc., can solve the problems of reducing the ZT value of thermal conductivity, etc., and achieve stability and reliability. , the preparation process is simple, the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

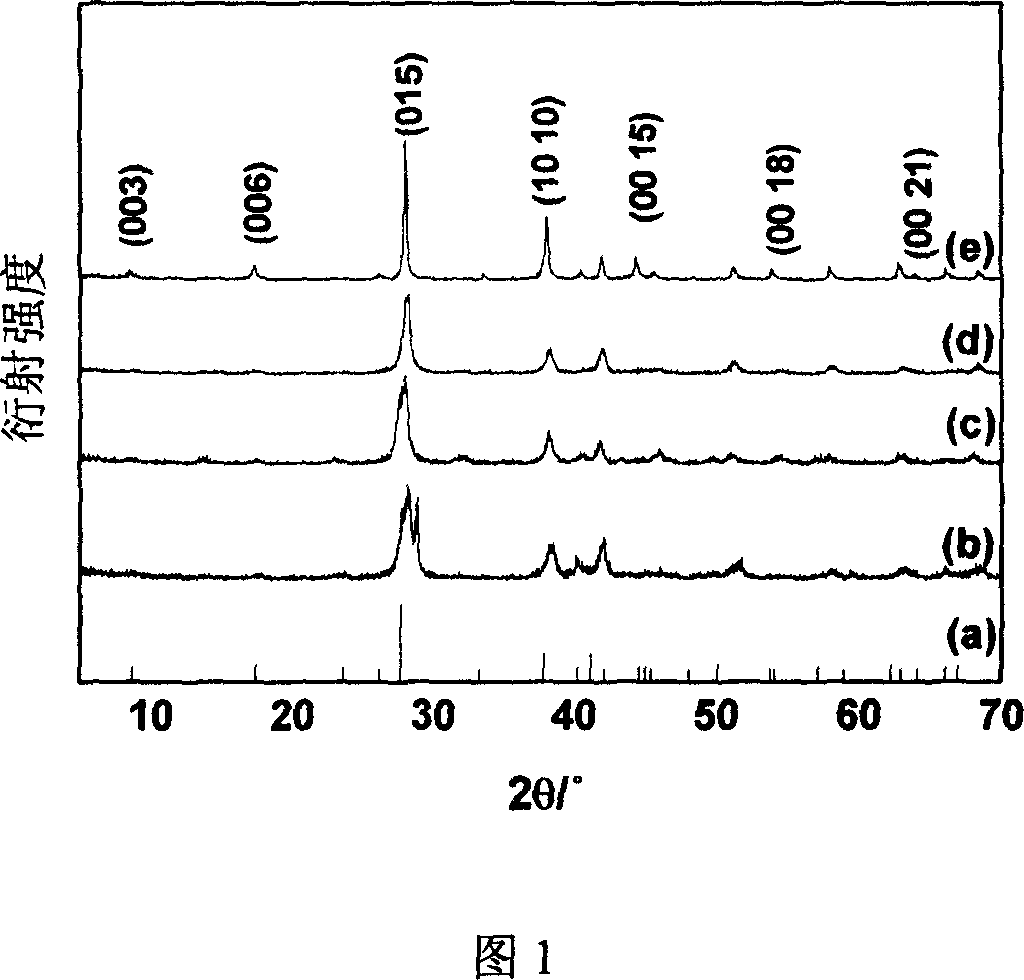

[0020] Example 1: N-type material whose matrix component is Bi-Te-Se

[0021] First weigh 21.15 g Bi, 18.01 g Te, 0.84 g Se and 0.04 g BiCl respectively 3 Four kinds of powders were then placed in a high-energy ball milling device, the ratio of ball to material was 20:1, the rotational speed was 800 rpm; the ball milling time was 24 hours. The charging and reclaiming process needs to be carried out in a glove box, and the protection of inert gas such as argon is introduced to avoid the introduction of oxidation problems during the preparation process.

[0022] The powder is then loaded into a graphite mold and placed in the SPS furnace. The sintering process was carried out under vacuum conditions, and the sintering temperature was 400 °C; the heating rate was 50 °C / min; the holding time was 4 min; The applied pressure was 60 MPa; finally, the samples were taken out after natural cooling to around room temperature. The flexural strength of the obtained bulk material is 82MP...

Embodiment 2

[0023] Example 2: P-type material whose matrix component is Bi-Sb-Te

[0024]Firstly, three kinds of powders, such as 6.01 g Bi, 11.08 g Sb and 24.12 g Te, were weighed respectively, and then placed in a high-energy ball milling device with a ball-to-material ratio of 20:1 and a rotational speed of 600 rpm; the ball milling time was 30 hours. The charging and reclaiming process needs to be carried out in a glove box, and the protection of inert gas such as argon is introduced to avoid the introduction of oxidation problems during the preparation process.

[0025] The powder is then loaded into a graphite mold and placed in the SPS furnace. The sintering process was carried out under vacuum conditions, and the sintering temperature used was 360 °C; the heating rate was 50 °C / min; the holding time was 2 min; The applied pressure was 60 MPa; finally, the samples were taken out after natural cooling to around room temperature.

[0026] The flexural strength of the obtained bulk ...

Embodiment 3

[0027] Example 3: Powder material with initial particle size less than 200nm

[0028] First, according to the same chemical ratio as in Example 1, each element powder was weighed, and then placed in a high-energy ball milling device, the ball-to-material ratio was 20:1, the rotational speed was 1000 rpm, and the ball milling time was 20 hours. The charging and reclaiming process needs to be carried out in a glove box, and the protection of inert gas such as argon is introduced to avoid the introduction of oxidation problems during the preparation process.

[0029] The powder is then loaded into a graphite mold and placed in the SPS furnace. The sintering process was carried out under vacuum conditions, and the sintering temperature was 320 °C; the heating rate was 60 °C / min; the holding time was 2 min; The applied pressure was 40 MPa; finally, the samples were taken out after natural cooling to around room temperature.

[0030] The flexural strength of the obtained bulk mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com