Wool fabric soft finish and application therefor

A technology for softening and finishing agent and wool fabric, applied in the field of wool fabric finishing auxiliaries, which can solve the problems of decreased softness, easy pilling, poor hand feeling, etc., and achieves the effects of good quality, good pilling performance and uniform cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Materials: warp and weft yarn metric count ≥ 70 S / 2×70 S / 2 and single weft metric count ≥ 35 S / 1, weight≤220g / m 2 Pure wool and blended fabrics. The pre-treatment of pure wool and blended fabrics adopts conventional technology, and the formula of the finishing agent for soft post-treatment is:

[0043] D 100 parts, E 6 parts, G 35 parts, H 2 parts

[0044] I.5 parts, J 3 parts.

[0045] Preparation of D:

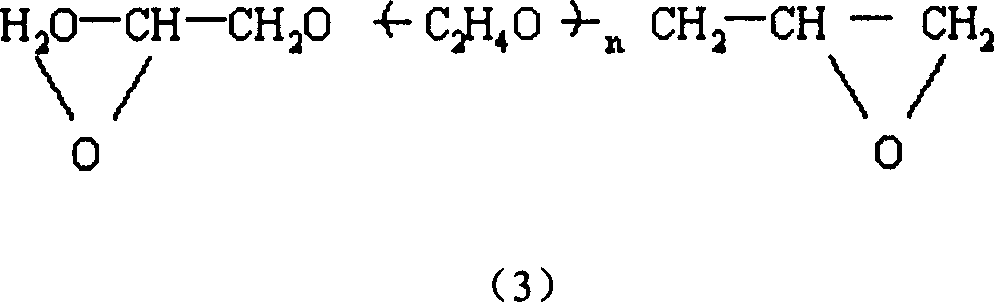

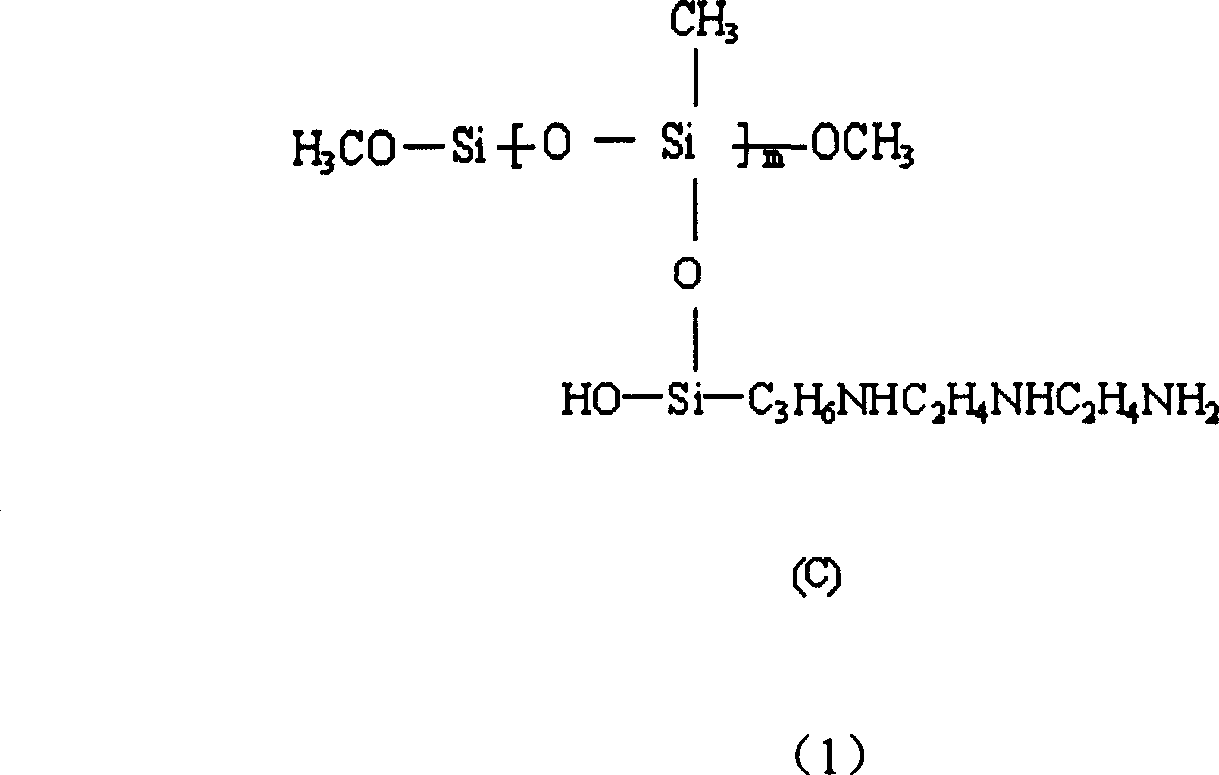

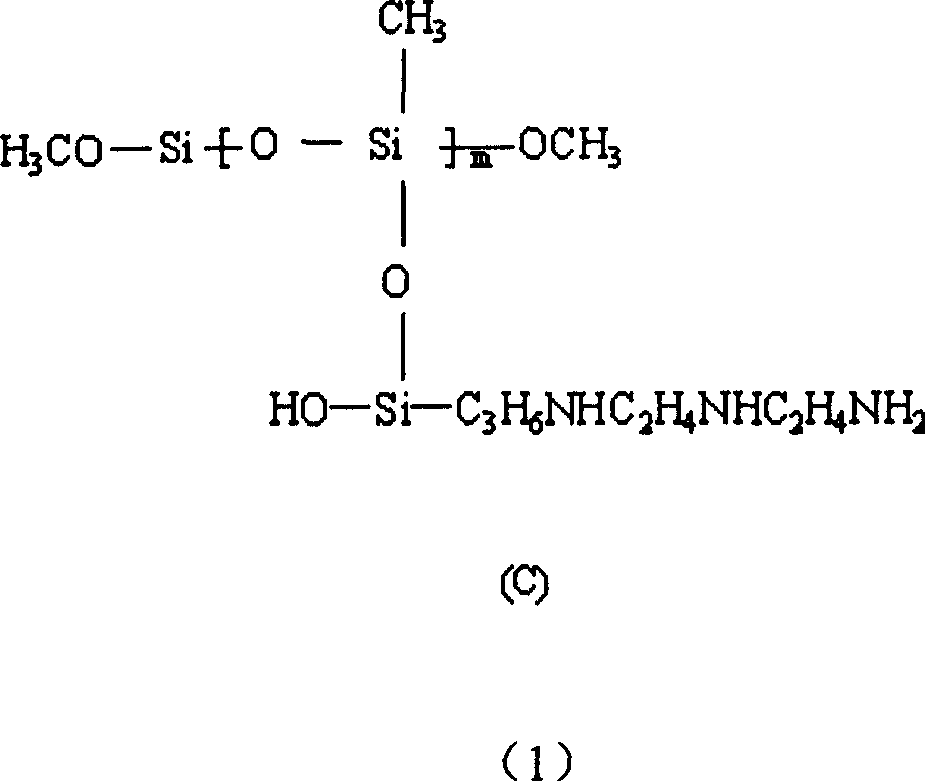

[0046] (A) represented by the formula (1) was mixed with γ-diethylenetriaminopropylmethyldimethoxysilane. Under the condition of pH 9, the coupling reaction was carried out at 80°C for 4 hours to obtain (C), wherein, m=47,

[0047] (A): (B)=6:1, weight ratio;

[0048] Add acetic acid to the product (C) to adjust the pH to 6, then add a mixed emulsifier at a temperature of 65°C, stir and emulsify to obtain the compound shown in formula D;

[0049]Said mixed emulsifier is isomeric tridecyl alcohol (EO) 12 and cetyl trimethyl ammonium chloride, and the weight...

Embodiment 2

[0057] Materials: Metric count of warp and weft yarns S / 2×70 S / 2 and single weft metric count S / 1, weight > 220g / m 2 For pure wool and blended fabrics, the pre-treatment adopts conventional technology, and the formula of the finishing agent for soft post-treatment is:

[0058] D 100 parts, E 4 parts, G 25 parts, H 1 part

[0059] I 2.5 parts, J 1 part.

[0060] Others are the same as Example 1, D, E, G, H, I and J are mixed, diluted into the aqueous solution of 30g / l, woolen fabric is dipped and rolled twice at 25 ℃ of temperature, and the liquid rolling rate is 60%, and the speed of a vehicle is 25%. m / min, dry at 125°C, and generate epoxy-siloxane block copolymerized wool fabric softening resin on the fabric, so that the wool fabric has a very significant effect of uniformity, softness and firmness.

[0061] The test results are shown in Table 1. The physical properties are shown in Table 2.

[0062] Table 1

[0063] Table 2

[0064] Note: "Shrinkage" is repres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com