Wash tub for drum washing machine

A technology for drum washing machines and washing tubs, applied in the field of washing tubs, which can solve the problems of easy deformation, unformed, and hindering the normal flow of injection resin 21, and achieve the effect of improving strength and rigidity and facilitating forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

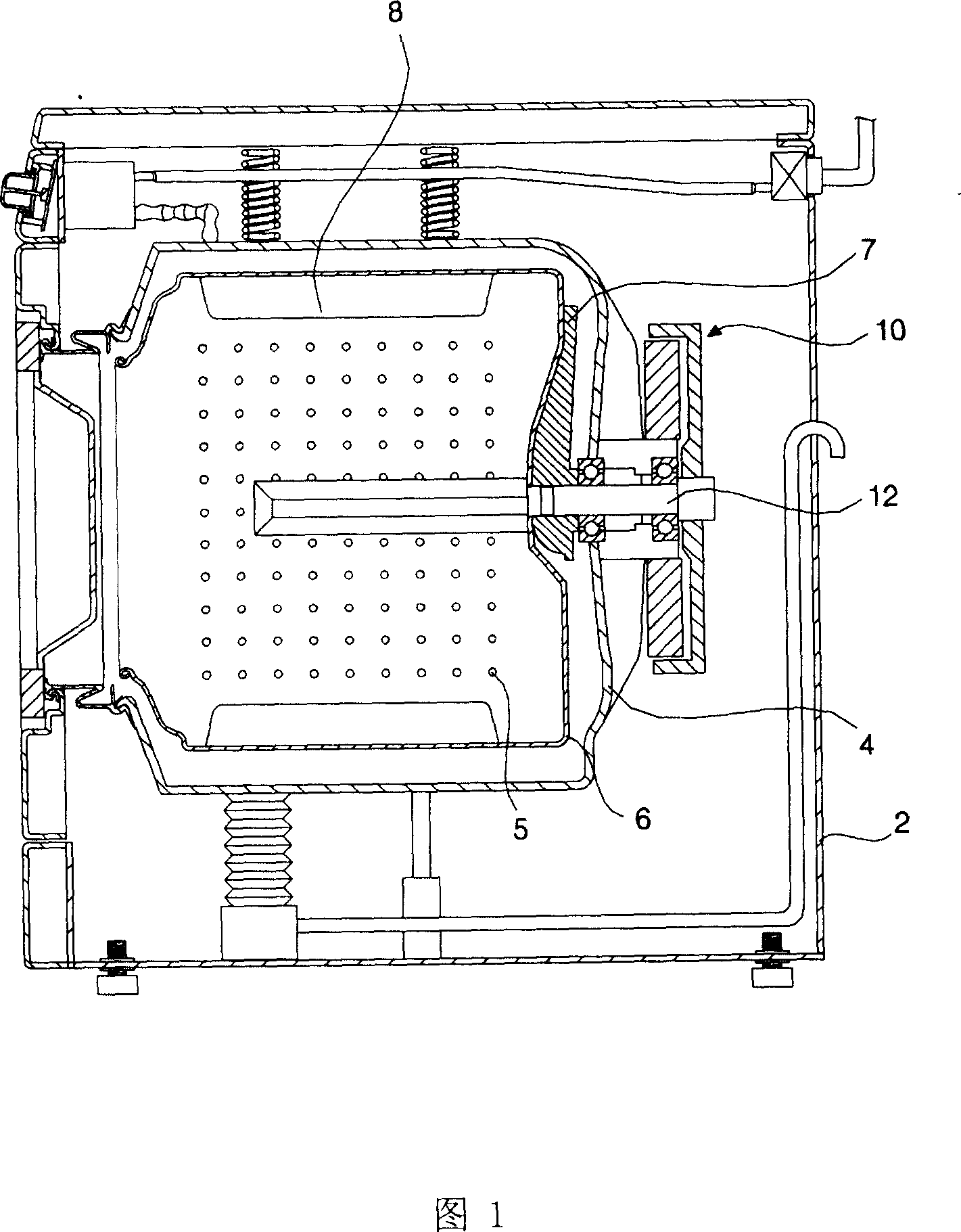

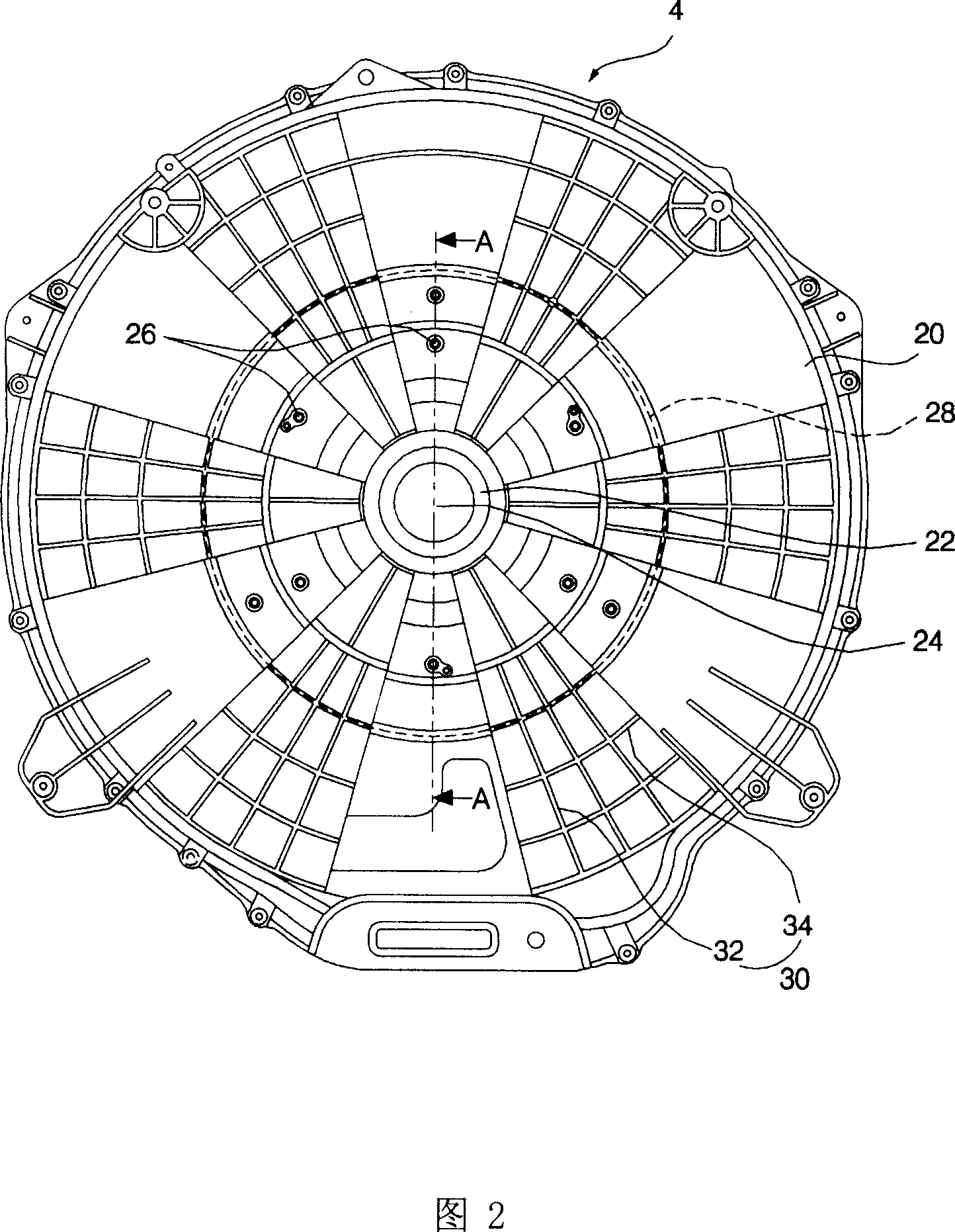

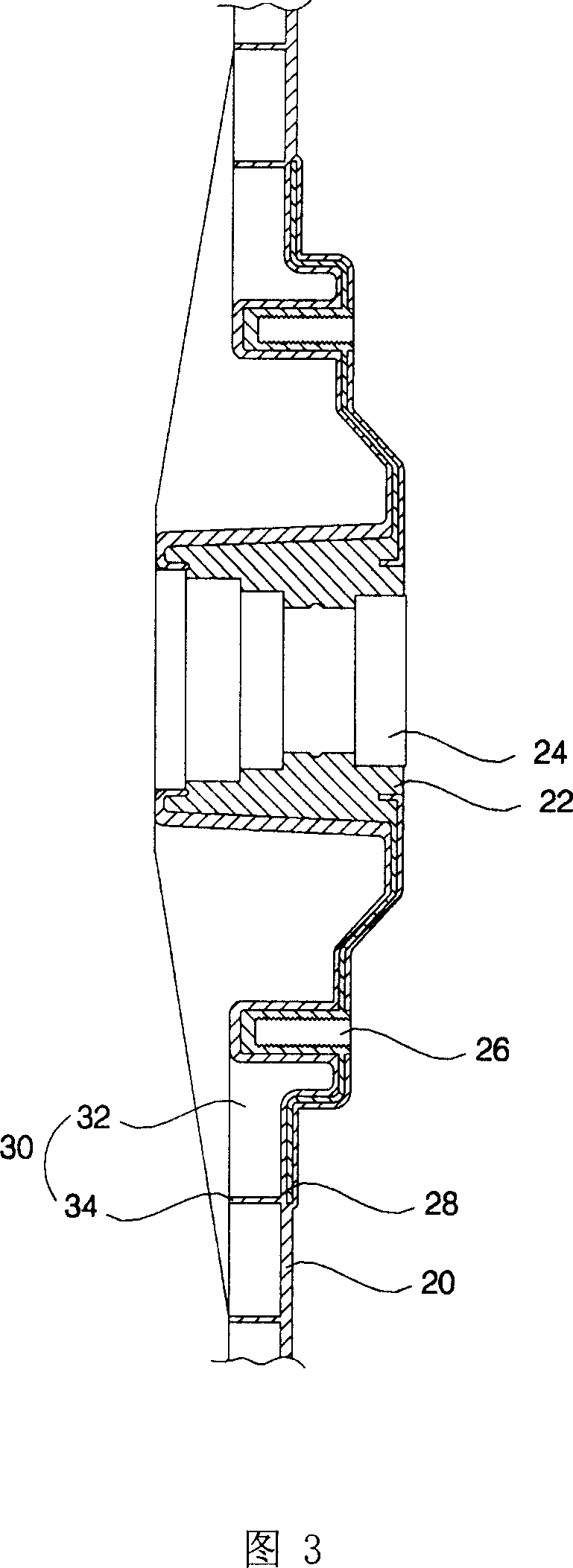

[0029] As shown in Figures 5 to 7, the washing tub 50 of the drum washing machine provided by the present invention mainly includes a drum 52 capable of rotating inside and a washing tub main body 60 with a motor 54 on the back; and a bearing sleeve 70 that can rotate the rotating shaft 58 on the supporting motor 54; Wherein the rotating shaft 58 of the motor 54 is connected with the drum 52 . The washing tub main body 60 is made of synthetic resin material, and its back center is formed with a hole not shown in the figure that can pass through the rotating shaft 58 on the motor 54, and the bearing sleeve 70 is inserted in the state of the back center. Formed by inlay injection molding. In order to ensure the strength and rigidity of the washing tub 50 and reduce its weight, the bearing sleeve 70 is preferably made of aluminum alloy, and its diameter is smaller than that of the back surface of the washing tub main body 60 . A central portion of the bearing sleeve 70 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com