Planet wheel inner hole drum-shaped raceway machining device

A processing device and planetary gear technology, which is applied in metal processing equipment, manufacturing tools, grinding racks, etc., can solve the problems of poor control of processing accuracy and difficulty in drum-shaped processing, so as to improve processing accuracy and improve Service life and precision, favorable effect of forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

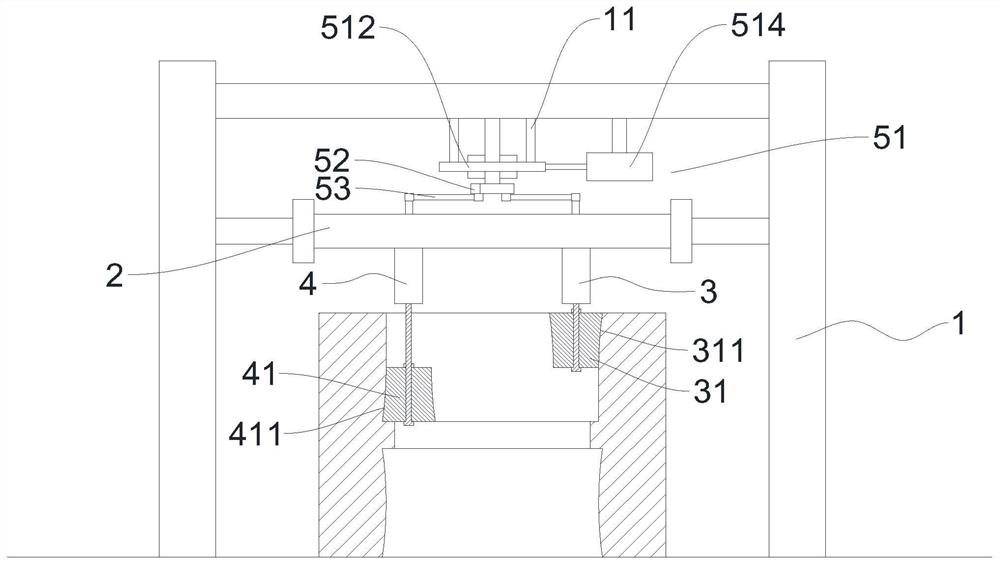

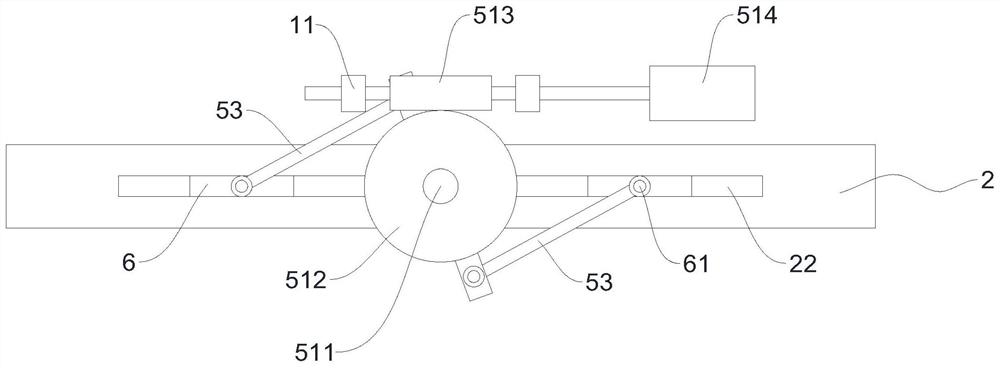

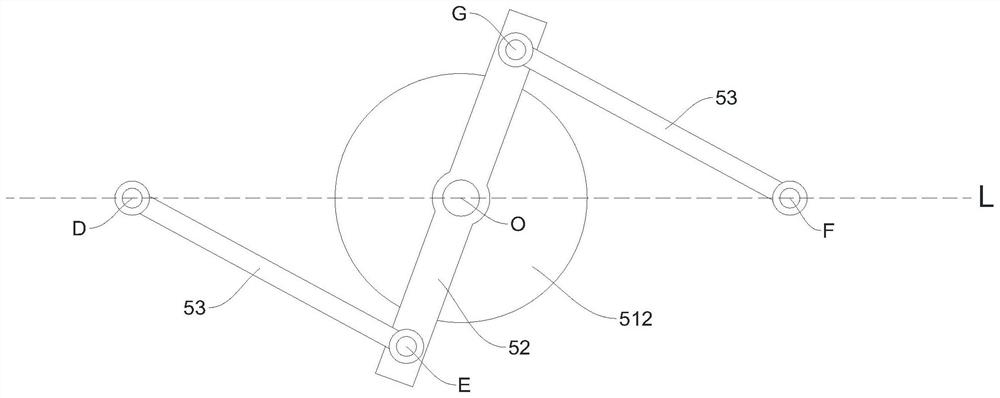

[0025] refer to figure 1 , is a kind of planetary wheel inner hole drum-shaped raceway processing device of the present invention, specifically, the processing device includes a support frame 1, a guide frame 2, a first grinder 3, a second grinder 4 and a driving mechanism 5; the guide The frame 2 is installed on the support frame 1, and the bottom of the guide frame 2 is provided with a chute 21 extending in the horizontal direction, and two slide blocks 6 are fitted in the chute 21 for conformal sliding; the first grinder 3 and the second grinder 4 are respectively installed on a slider 6; the first grinder 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com