Construction method for middle inspection well through reverse construction method

An intermediate inspection and construction method technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as soil loosening, settlement of buried objects in inspection wells, and greater influence of surrounding buried objects, so as to facilitate forming and improve The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

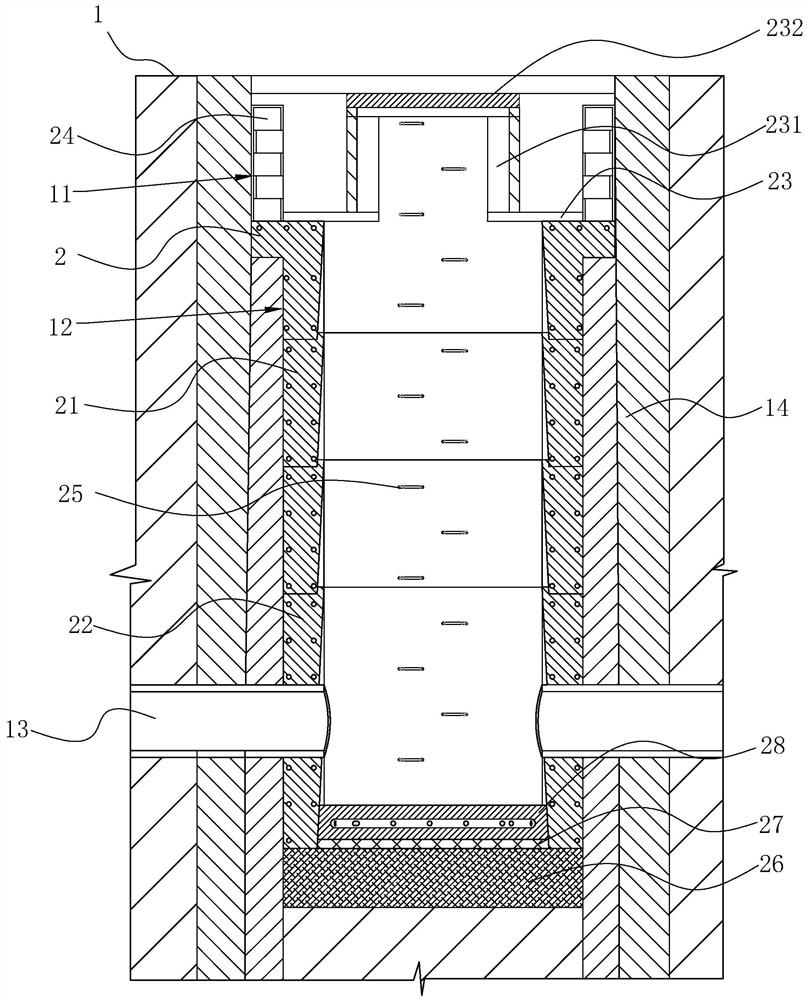

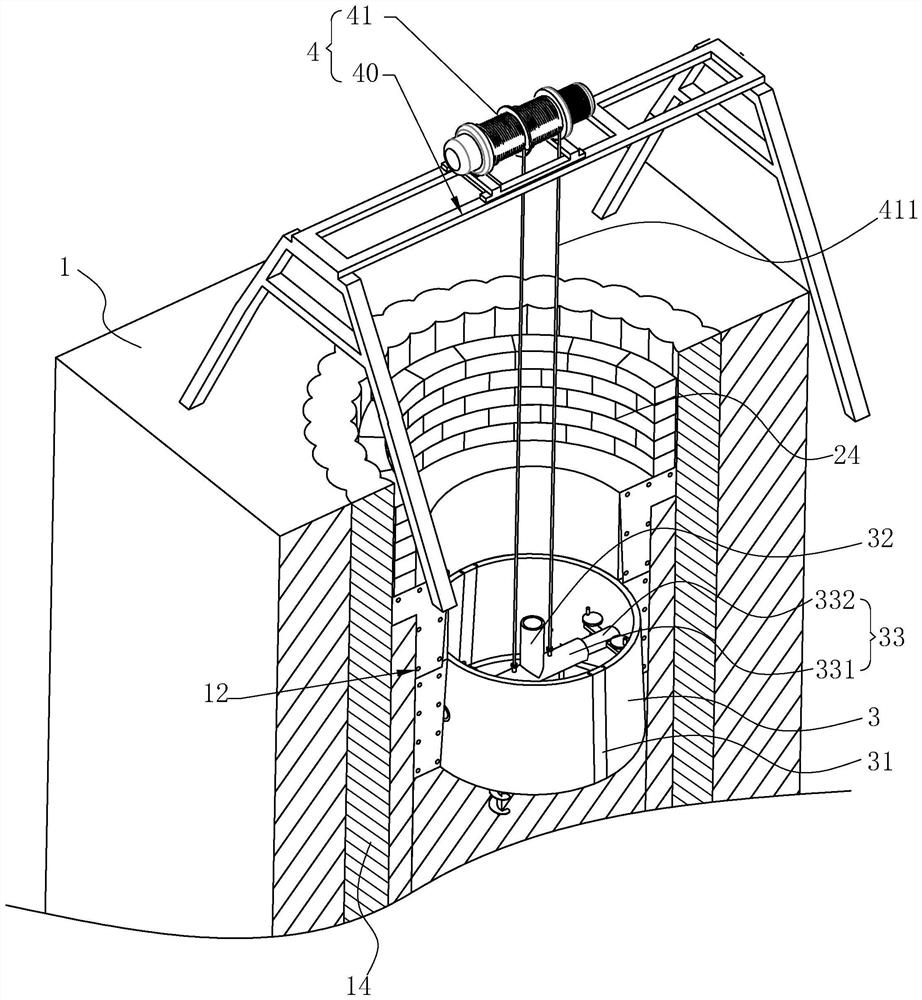

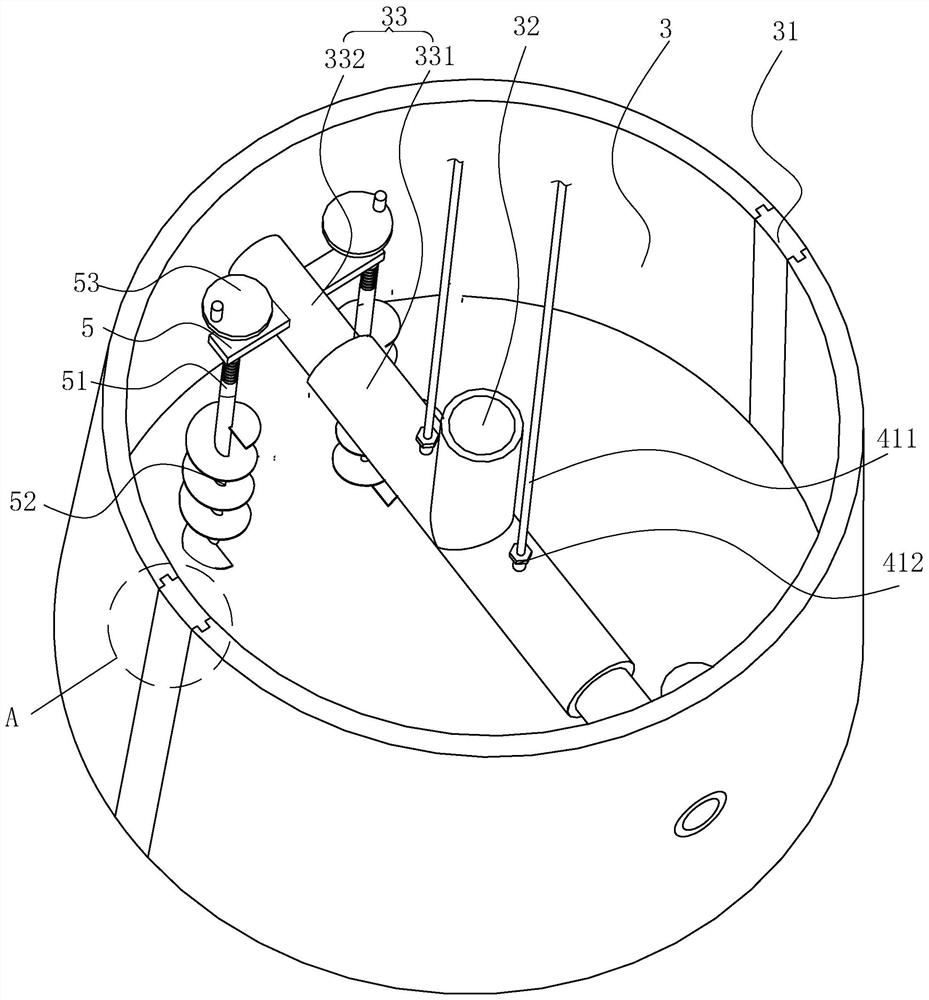

[0048] The following is attached Figure 1-4 This application is described in further detail.

[0049] The embodiment of the present application discloses a construction method of an intermediate inspection well by the reverse method, referring to figure 1 and figure 2 , including the following steps:

[0050] S1: prefabricated cover plate 23, well shaft 231, well cover 232, annular formwork, lifting component 4 and several pouring formwork, lifting component 4 is connected with annular formwork; cover plate 23 well shaft 231 and well cover 232 are all reinforced concrete structures;

[0051] S2: Combined with the design drawings, stake out the axis of the inspection well to the road surface through the total station and other related instruments; determine the construction area of the inspection well by setting out the axis of the inspection well to the ground 1;

[0052] S3: Build support structures around the construction area of the inspection well, and the project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com