Full-automatic colored paper box assembly line cutting apparatus

A fully automatic, production line technology, used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of production bottlenecks, large turnover of semi-finished products, long operation time, etc. The effect of fewer people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

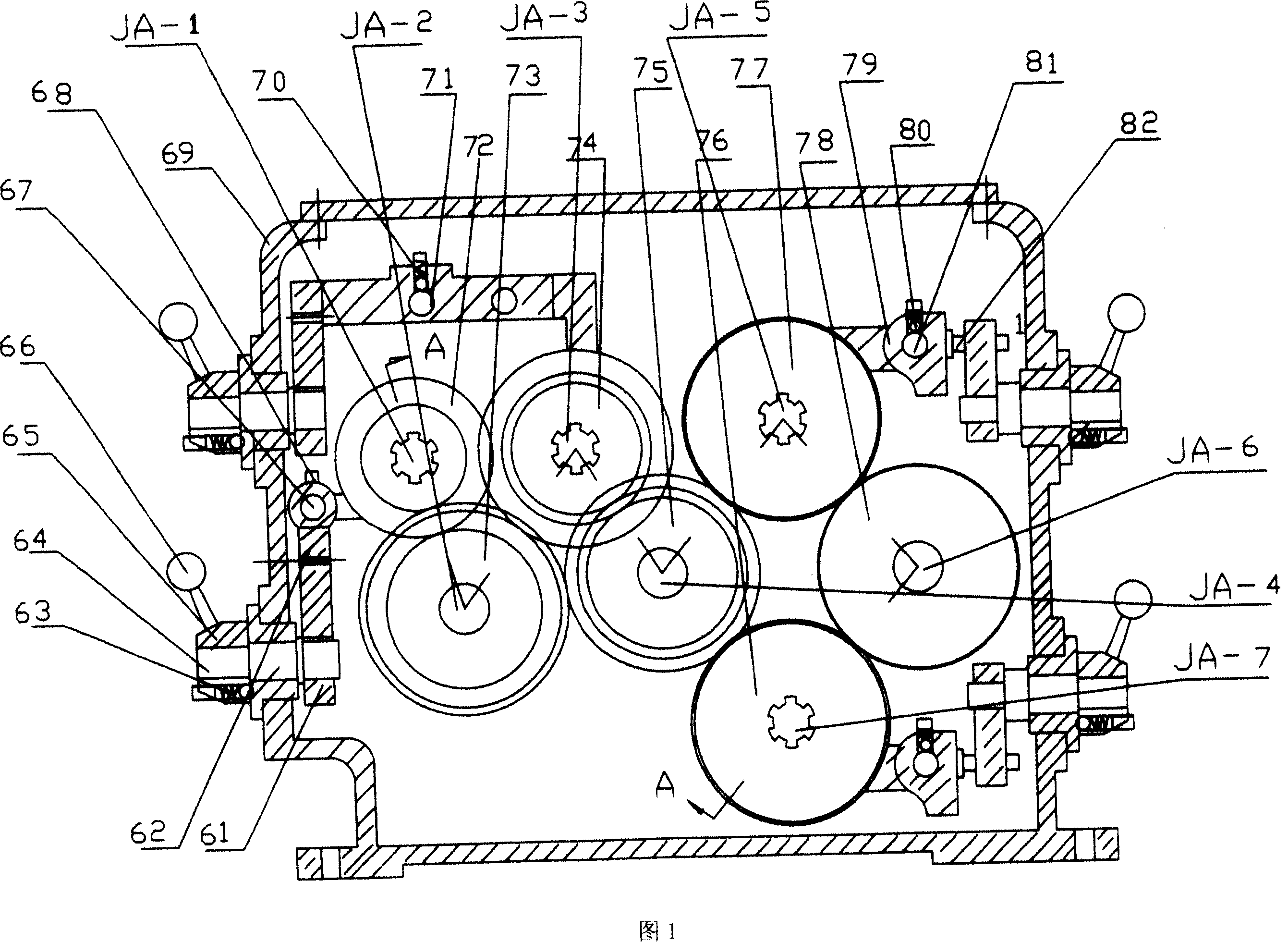

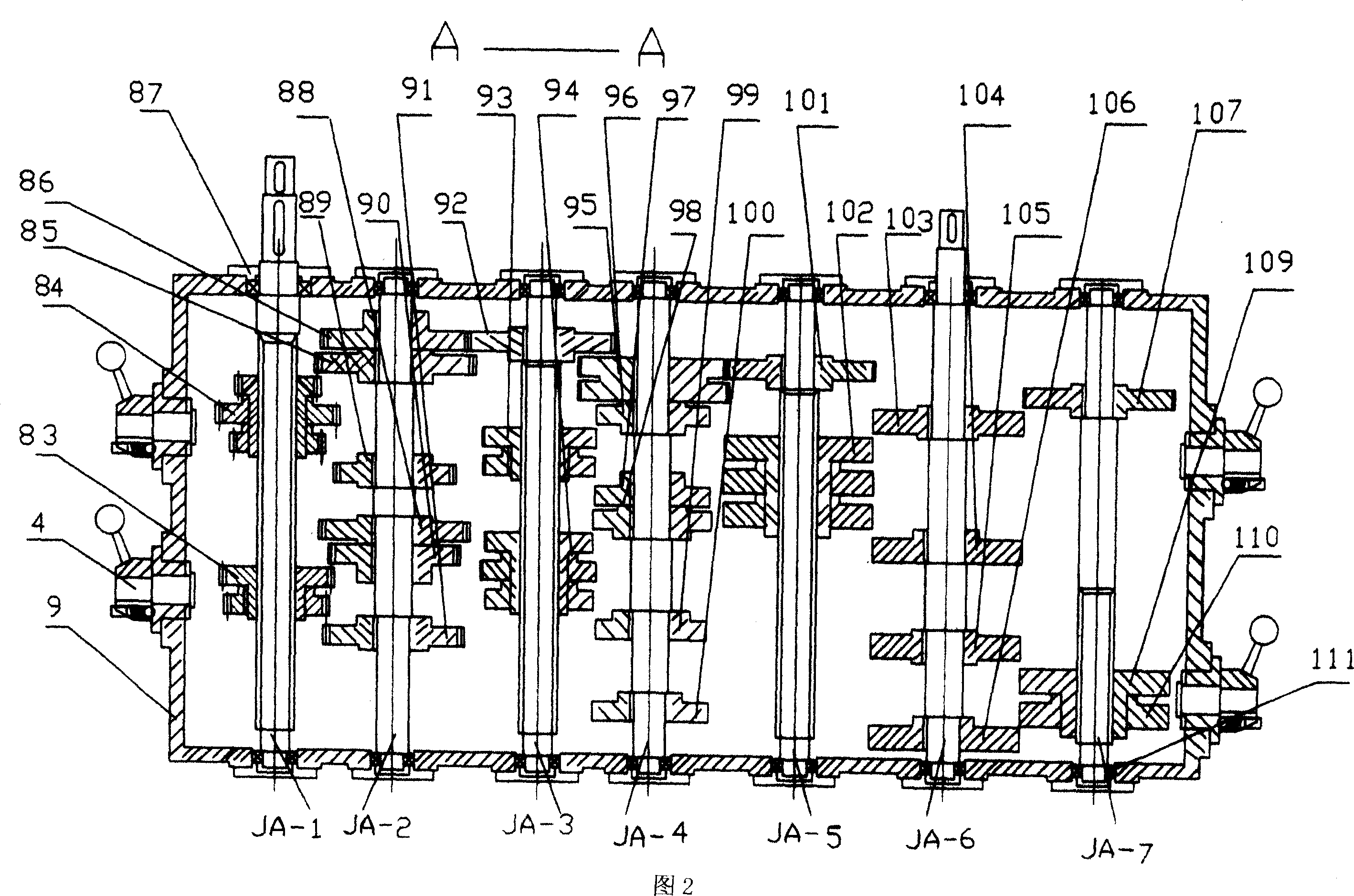

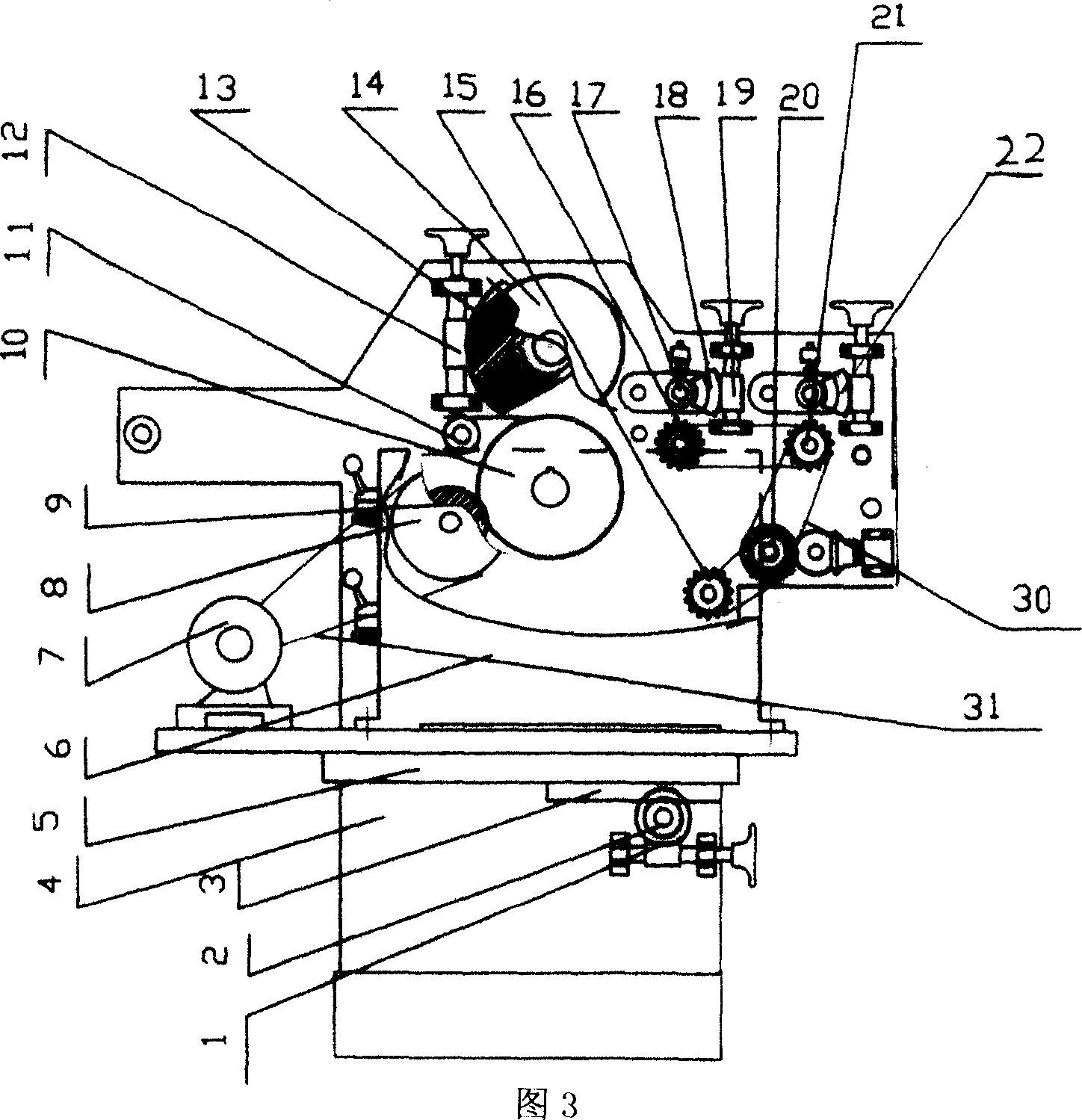

[0026] 3-7, the present invention includes a frame, a cutting mechanism arranged above the frame, a transmission mechanism arranged above the frame to connect the cutting mechanism and a paper feeder, a gearbox 6 arranged on one side of the cutting mechanism, and a transmission mechanism arranged on the side of the cutting mechanism. One side of the frame is connected to the main speed-regulating motor 7 of the gearbox 6, and the frame includes a machine body 45, a sliding chassis 4 and a frame adjustment mechanism installed on the sliding chassis 4, and the cutting mechanism includes The cutting knife, the cutting knife position adjustment mechanism and the paper adjustment mechanism arranged beside the cutting knife, the transmission mechanism includes a speed transmission mechanism connected to the gearbox, a transmission rod and a transmission bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com