Novel dry mineral pigment containing calcium carbonate, aqueous suspension containing said pigment, and the uses thereof

A technology of mineral pigments, calcium carbonate, applied in the direction of fibrous fillers etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This example serves to illustrate the prior art and relates to various preparation methods of prior art pigments.

[0082] test n o 1

[0083] This test illustrates the preparation of a prior art pigment in which 0.5 kg of natural calcium carbonate of the Norwegian marble type, calculated as dry pigment, is diluted with distilled water in a 10 liter container using a Sedigraph from the company Micromeritics TM The particle size distribution measured by the 5100 is 65% by weight of particles having a diameter of less than 1 μm in the form of a 75% dry content aqueous suspension dispersed with 0.6% polyacrylate de soude until diluted to obtain dry matter Aqueous suspension at a concentration of 15% by weight. The suspension thus formed was then treated with 10% phosphoric acid (in a 10% by weight solution) at 65° C. for 20 minutes with stirring at 500 rpm for 20 minutes. Thereafter, the pH is adjusted to 8-8.5 with a lime suspension having a concentration equal to 10%...

Embodiment 2

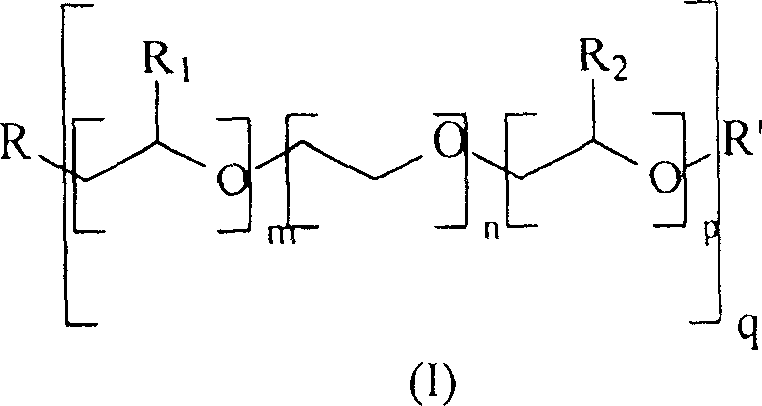

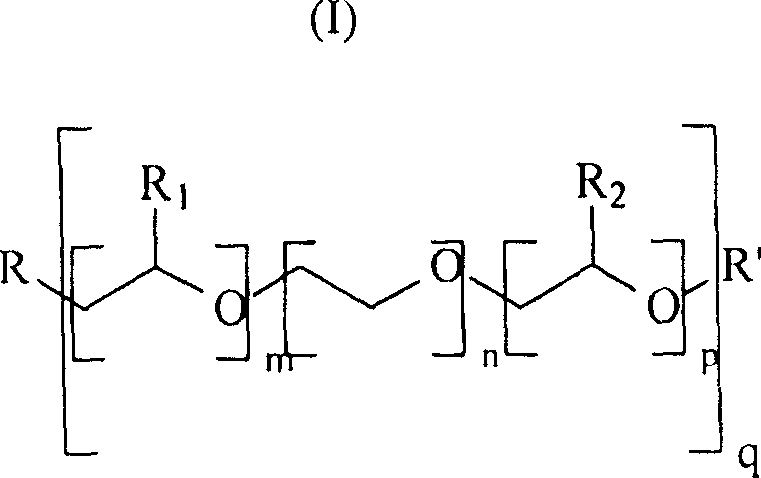

[0099] This example illustrates the invention and relates to a process for the production of dry mineral pigments comprising products formed in situ from multiple reactions between natural calcium carbonate and a or a variety of medium strength to strong H 3 o + One or more reaction products of the ion donor and the carbonate with the gaseous CO formed in situ and / or supplied externally 2 One or more reaction products of and one or more compounds of general formula R-X; and mineral pigments obtained by the process.

[0100] test n o 4

[0101]This test illustrates the invention and relates to the process for obtaining the pigments of the invention, wherein the treatment with a 2% mixture of palmitic and stearic acids (approximately 1 / 1 weight ratio) takes place during the reaction of calcium carbonate with phosphoric acid.

[0102] For this purpose, in a 10 liter ESCO reactor, 0.746 kg of natural calcium carbonate of the French chalk type, calculated as dry pigment, was di...

Embodiment 3

[0216] This example relates to the use of pigments according to the invention as rheology modifiers for the preparation of polyvinyl chloride (PVC) based plastisols.

[0217] The filled plastisols were prepared by mixing the unfilled PVC-based plastisols with calcium carbonate or the mineral pigment to be tested in a container with a diameter of 7 cm and homogenizing with a spatula. The total weight of the mixture is 200 g. Subsequent use of Pendraulik TM The mixture was dispersed for 2 minutes in an LD50 laboratory mixer with a dispersing disc having a diameter of 5 cm and a rotational speed of the disc at 2700 rpm (manually adjusted to position 3).

[0218] When dispersion is complete, use Rheomat 120 at 20°C TM Viscosity is measured by machine according to standard DIN 125.

[0219] After aging at a temperature of 23°C for 24 hours and 30 days, the pour point was determined using the Bingham model well known to those skilled in the art.

[0220] In all tests of this ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com