Lithium ion secondary battery

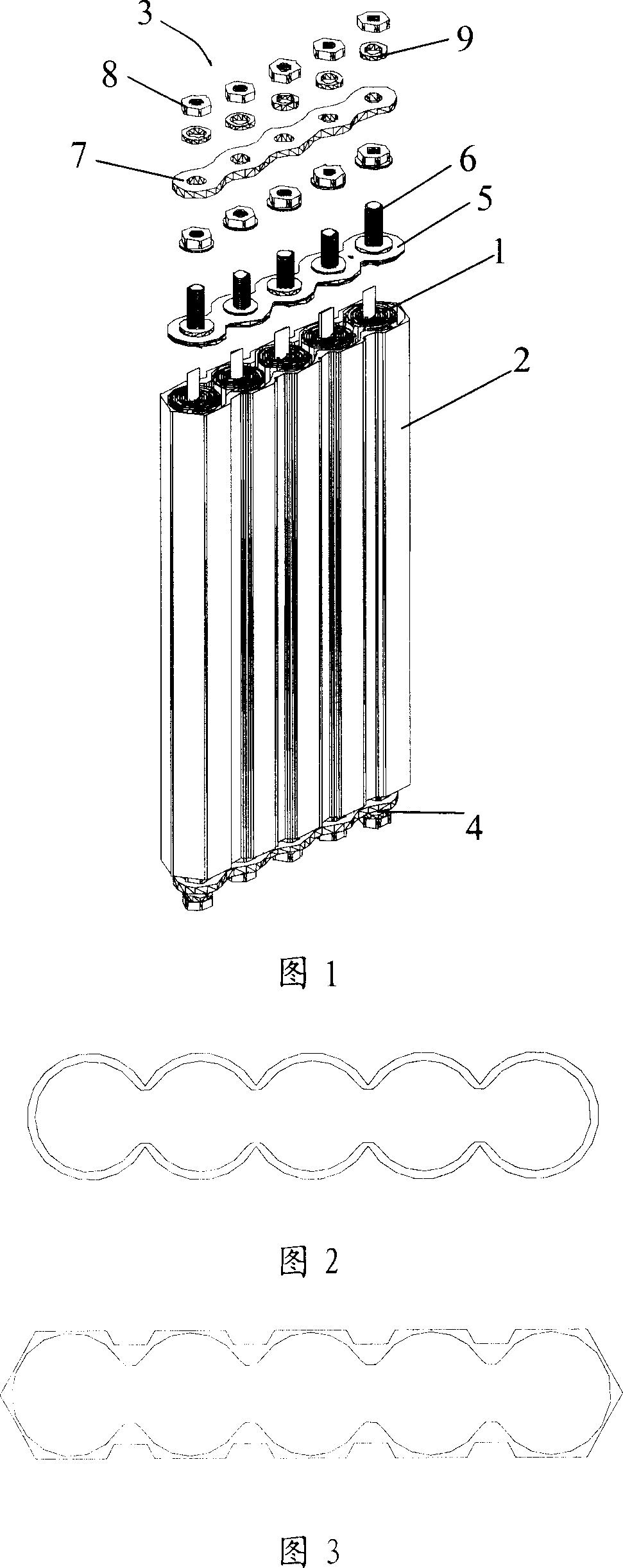

A secondary battery and lithium-ion technology, which is applied in secondary batteries, secondary battery manufacturing, battery pack components, etc., can solve the problem of difficult winding, low conduction capacity, and long pole piece of single-pole core winding structure. and other issues, to achieve the effect of expanding the heat dissipation surface area, easy preparation process, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Pole core preparation:

[0047] Positive sheet preparation process: Dissolve PVDF (polyvinylidene fluoride) in NMP (N-methylpyrrolidone), and LiCoO 2 and acetylene black are added to the solution, mixed thoroughly to make a slurry, the composition of which is LiCoO 2 : Acetylene black: PVDF (polyvinylidene fluoride) = 92:4:4. This slurry was uniformly coated on a 20 μm aluminum foil, and dried at 120° C. After cutting and rolling, a positive electrode sheet with a thickness of 120 μm was obtained.

[0048] Negative sheet preparation process: Dissolve PVDF (polyvinylidene fluoride) in NMP (N-methylpyrrolidone), add artificial graphite to the solution, and mix thoroughly to form a slurry, which consists of artificial graphite: PVDF (poly vinylidene fluoride)=95:5. Furthermore, this slurry was uniformly coated on the copper foil of 20 micrometers, and it dried at 120 degreeC. After cutting and rolling, a negative electrode sheet with a thickness of 120 μm was obtai...

Embodiment 2

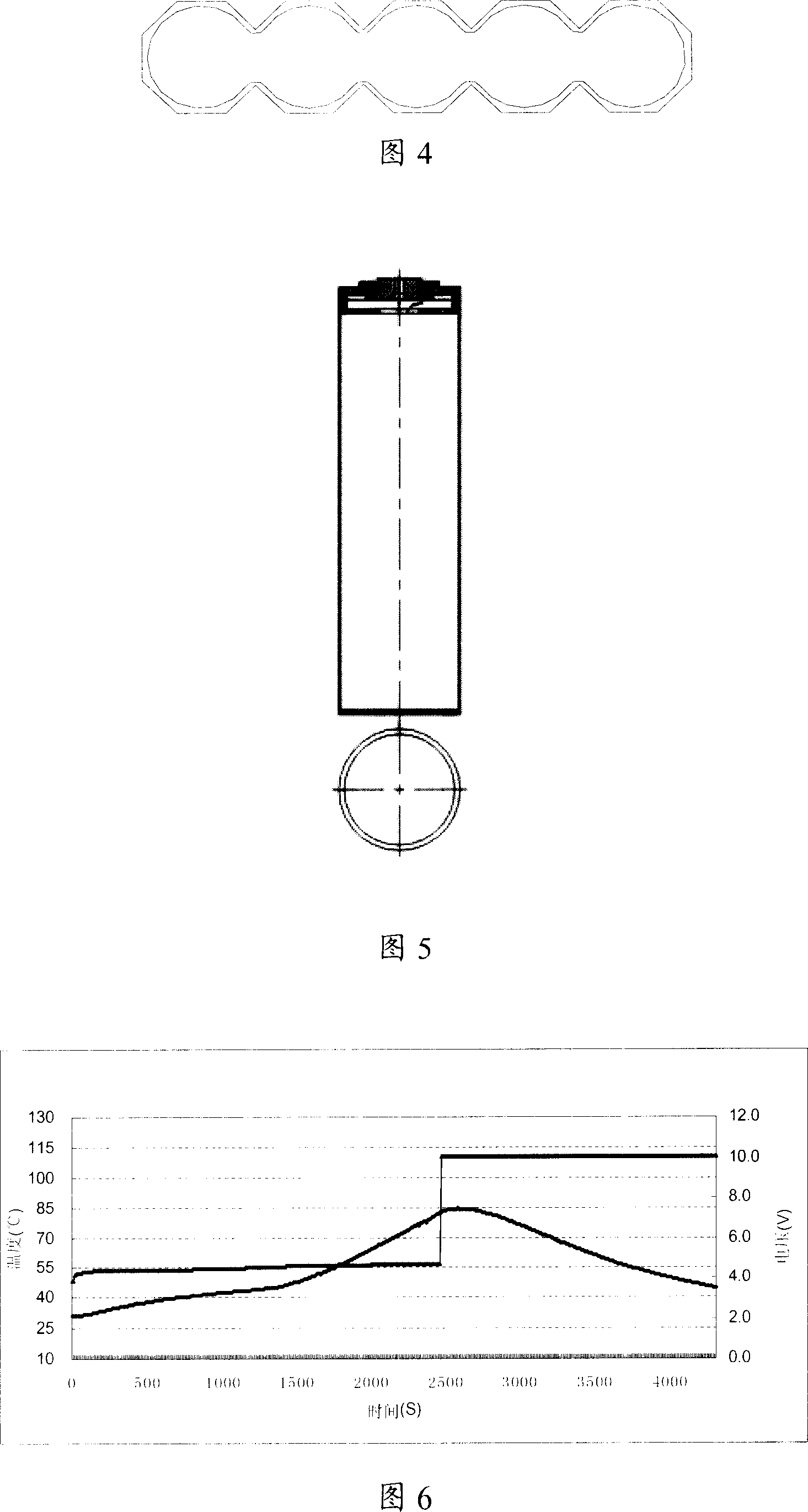

[0053] The battery pole core described in Example 1 and the battery assembly method similar to Example 1 are adopted, except that the top view of the outer wall of the casing is a cylindrical structure in which five hexagonal structures are arranged side by side and connected to each other as shown in FIG. 3 .

Embodiment 3

[0055] The battery pole core described in Example 1 and the battery assembly method similar to Example 1 are adopted, except that the top view of the outer wall of the housing is a cylindrical structure in which five octagonal structures arranged side by side are connected to each other as shown in FIG. 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

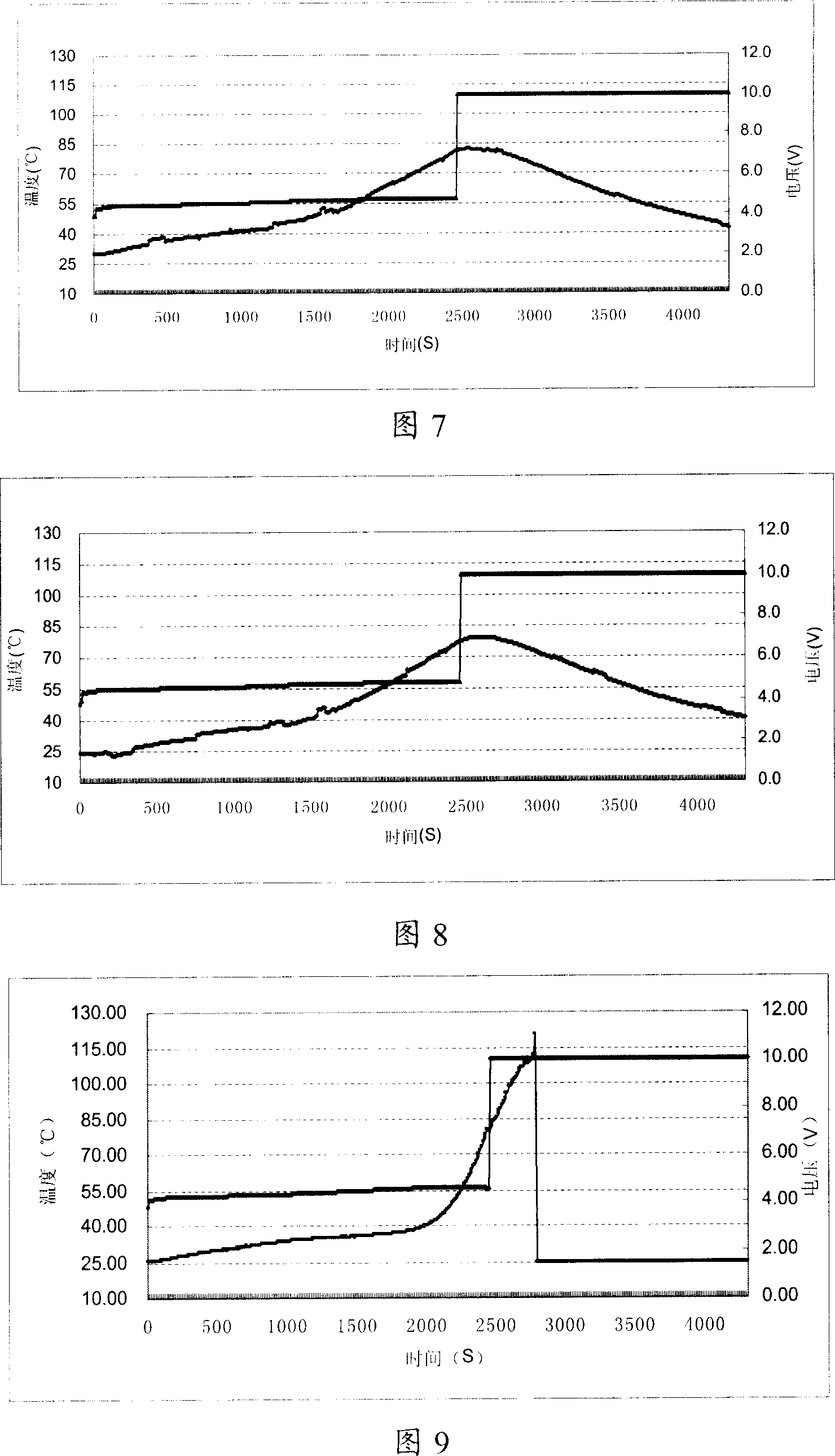

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com