Ternary microemulsified diesel oil and method for preparing same

A technology of diesel oil and polyol amine, which is applied in the field of ternary microemulsion diesel oil and its preparation, can solve the problems of high cost of emulsifier, expensive emulsification equipment, short storage period of emulsified oil, etc., and achieve low production cost and excellent storage stability Good, low emulsification temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 9.1 kg of commercially available mixed fatty acids and 0.9 kg of mixed polyol amines into the reaction kettle, and stir while heating. When the temperature rises to 90°C, maintain the reaction temperature, continue stirring for 10 minutes, and terminate the reaction to obtain mixed fatty acid amine soaps. , and leave it for later use.

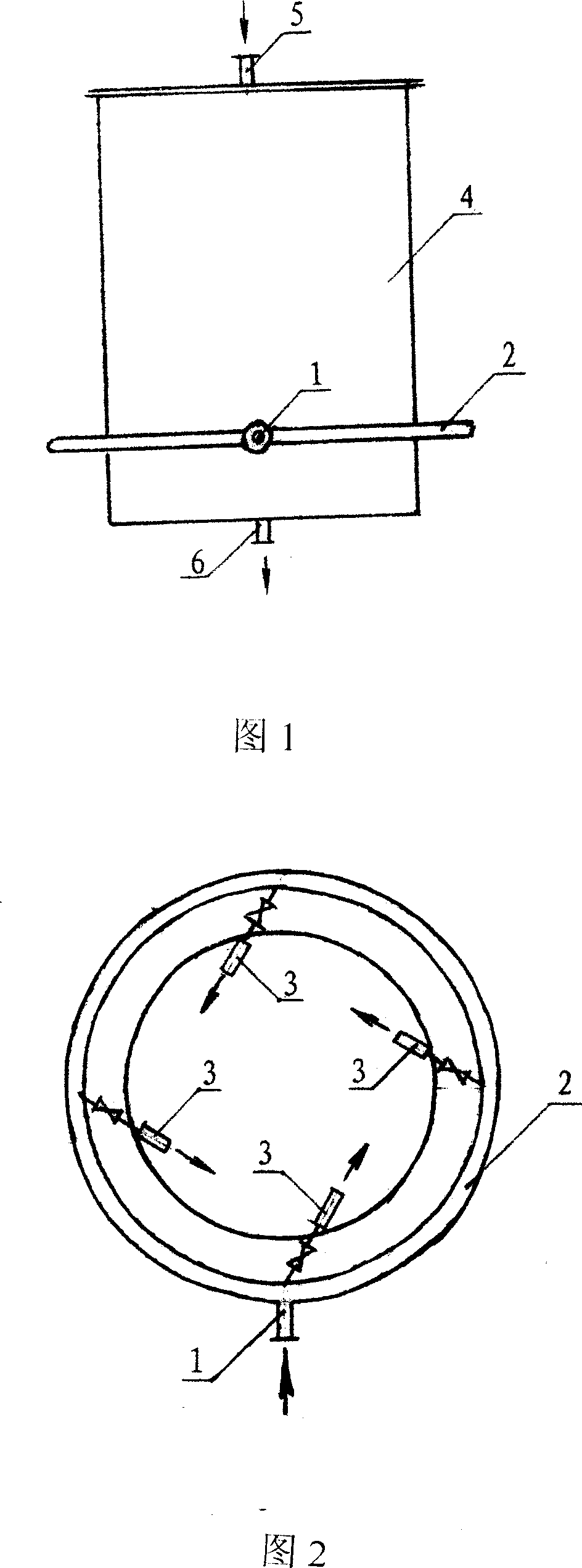

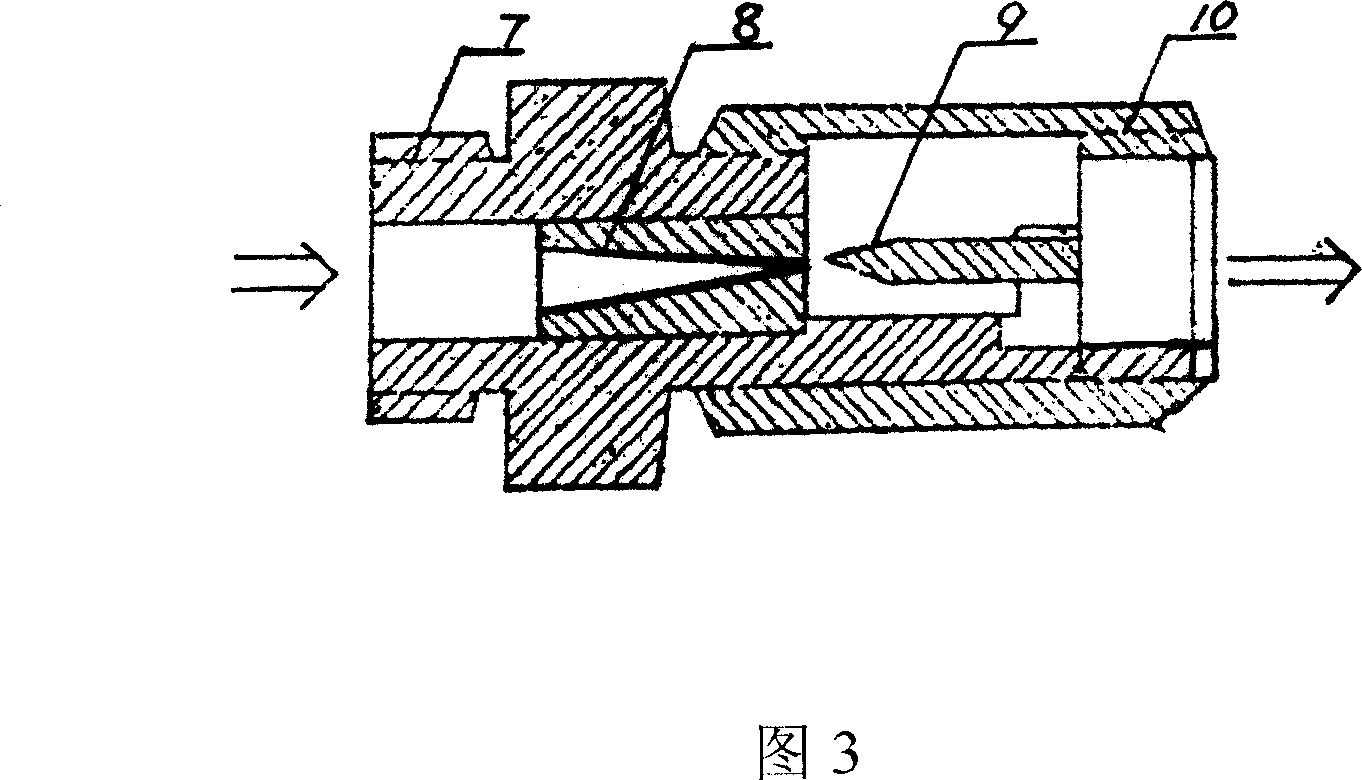

[0032] Take 10kg of the above-mentioned mixed fatty acid ammonium soap and dissolve it in 75kg of diesel oil, add it to an emulsifier with a steam reed whistle, while stirring with steam, add 10kg of deionized water slowly while heating, emulsify for 30 minutes, and the temperature of the material reaches 60°C. Transparent microemulsion, through metering, 5kg of water vapor is condensed in the process, the weight percentage of ingredients of synthetic mixed fatty acid ammonium soap is 91% of mixed fatty acid, 9% of mixed polyol amine, and the weight percentage of ingredients of microemulsified diesel oil is mixed fatty acid Ammonium ...

Embodiment 2

[0038] The preparation method is the same as above, and the material ratio is as follows (weight percentage):

[0039] When synthesizing ammonium soap: mixed fatty acid 90%, mixed polyol amine 10%.

[0040] When preparing emulsified diesel oil: mixed fatty acid ammonium soap 14%, water 20%, diesel oil 66%.

Embodiment 3

[0042] The preparation method is the same as in Example 1, and the material ratio is as follows (weight percentage): when synthesizing mixed fatty acid ammonium soap: 95% mixed fatty acid, 5% mixed polyol amine.

[0043] When preparing emulsified diesel oil: mixed fatty acid ammonium soap 8%, water 7%, diesel oil 85%.

[0044] The fatty acid ammonium soap of a single component can also be used in the above components, which is the synthesis of a single component fatty acid and a single component alcohol amine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com