Alkalline battery-use anode active material and production method therefor, and alkalline battery

A cathode active material, alkaline battery technology, applied in the direction of alkaline storage battery electrodes, alkaline storage batteries, battery electrodes, etc., can solve problems such as the inability to use high energy density, the inability to obtain large-capacity alkaline batteries, and the lack of battery capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] [Example]

[0096] The embodiment of the present invention will now be described with reference to FIGS. 1 to 6.

[0097] In this example, a cathode active material was manufactured, and an alkaline battery using the cathode active material was manufactured.

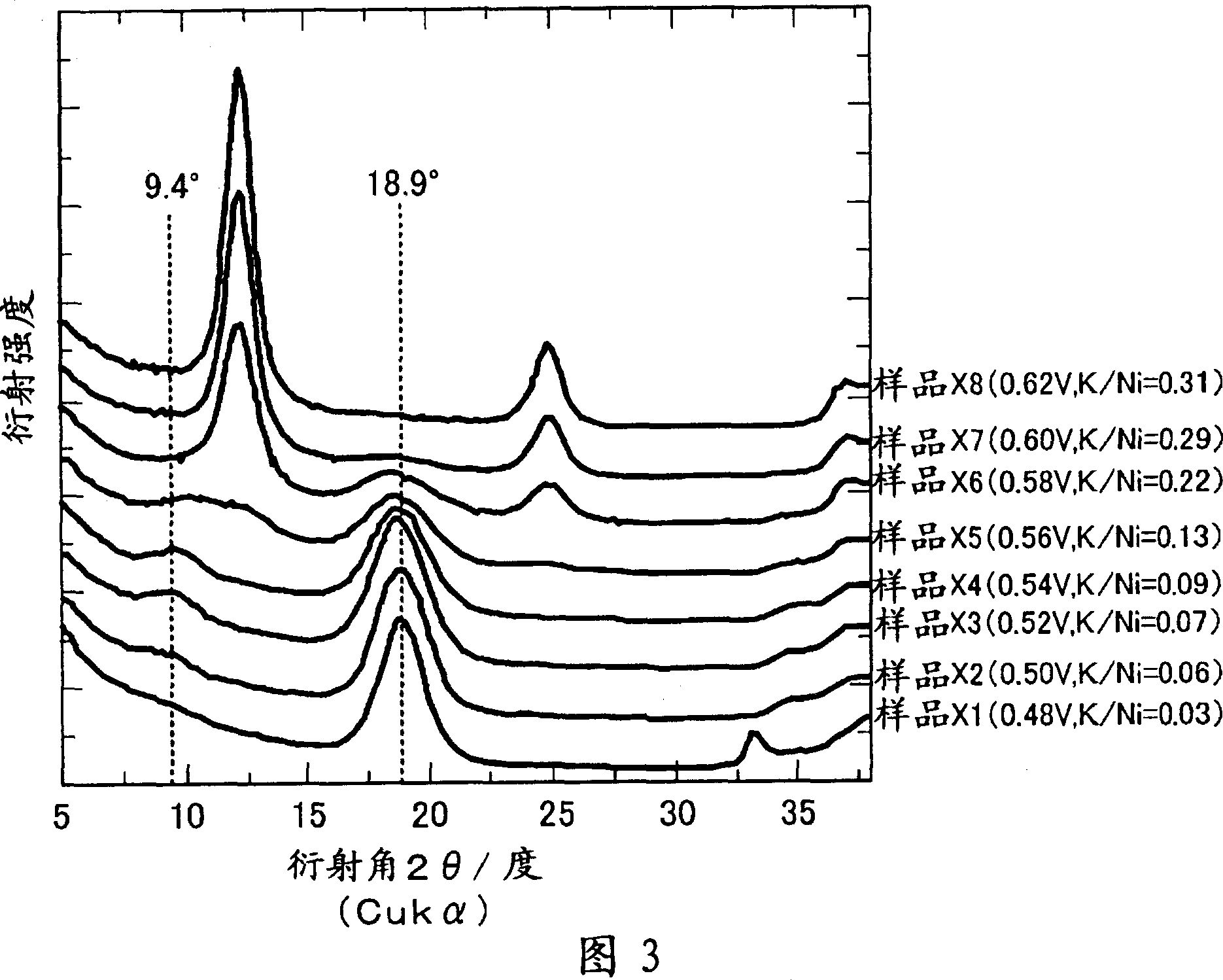

[0098] The cathode active material of this embodiment is used for an alkaline battery including nickel oxyhydroxide having a platelet structure. When X-ray diffraction is performed using CuKα rays, the cathode active material has diffraction peaks positioned in the range of diffraction angle 2θ of 8.4 degrees to 10.4 degrees.

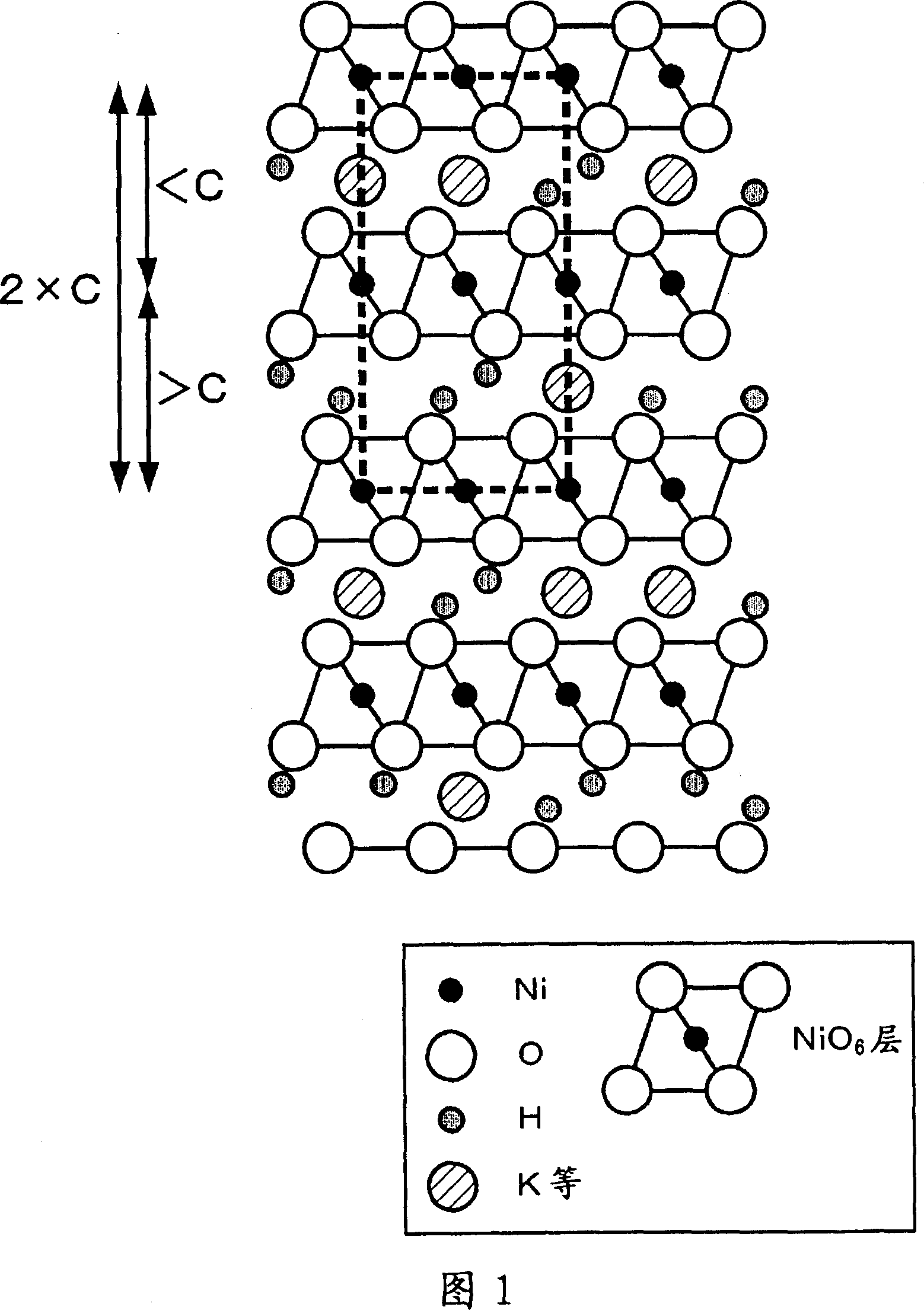

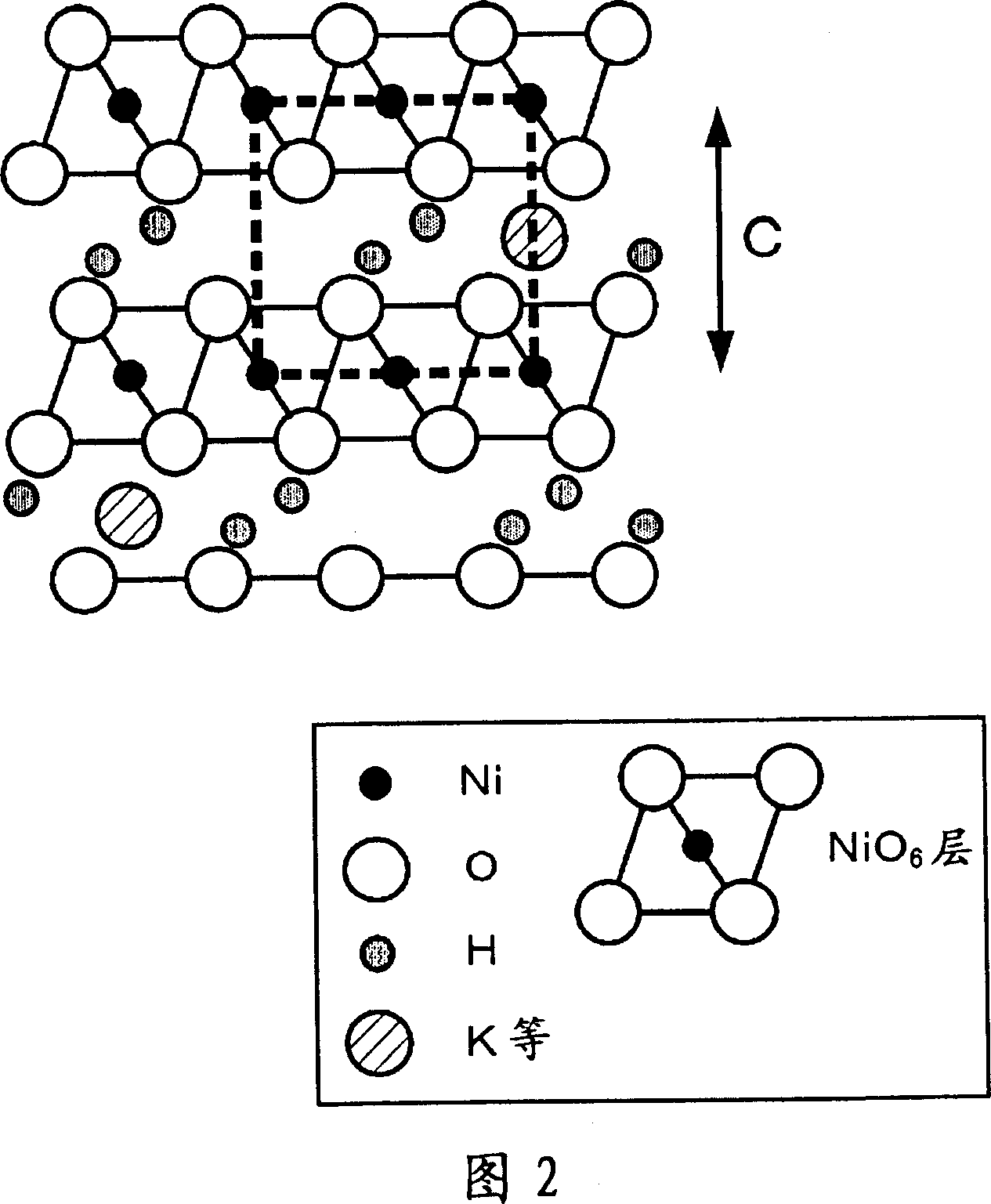

[0099] The cathode active material of the present embodiment includes β'-type nickel oxyhydroxide, which has diffraction peaks positioned in the range of diffraction angle 2θ of 8.4 degrees to 10.4 degrees when X-ray diffraction is performed using CuK α rays. The crystal structure of this β'-type nickel oxyhydroxide is shown in Fig. 1. As shown in the same figure, β'-type nickel oxyhydroxide ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com