Method for handling electric circuitry, and structure

A conductive circuit and manufacturing method technology, applied in the direction of conductive pattern formation, printed circuit components, etc., can solve the problems of inability to increase circuit layout density, easy to create public nuisance, copper foil falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

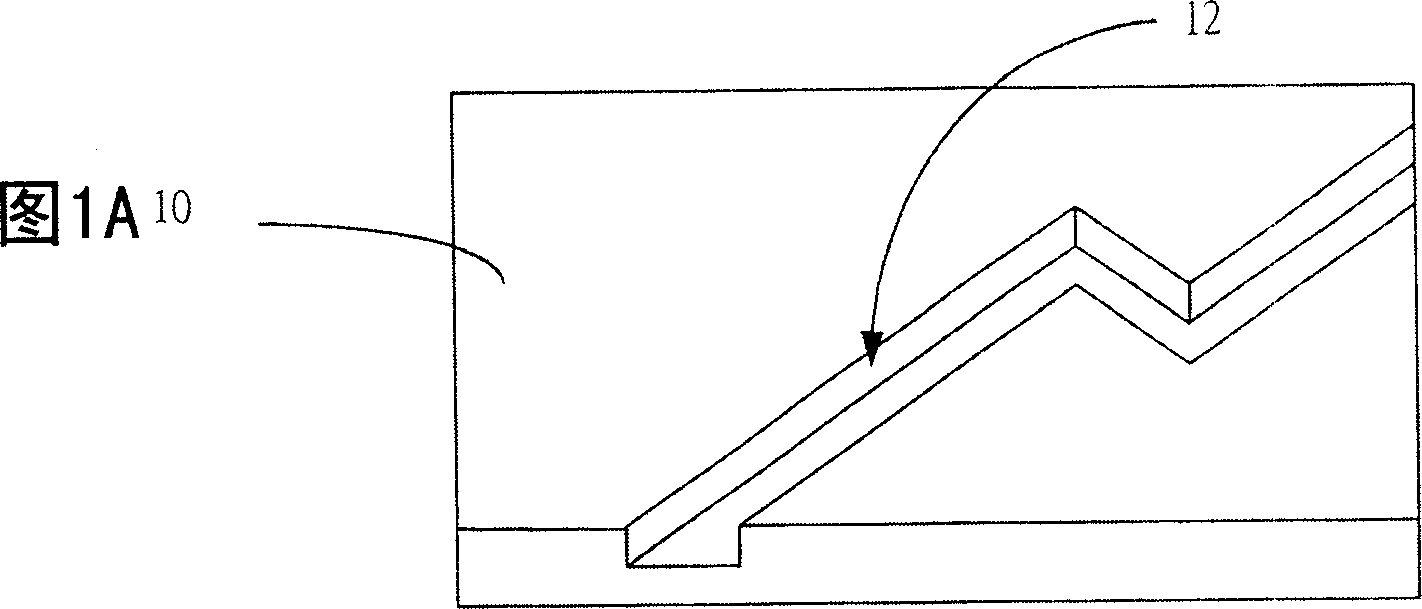

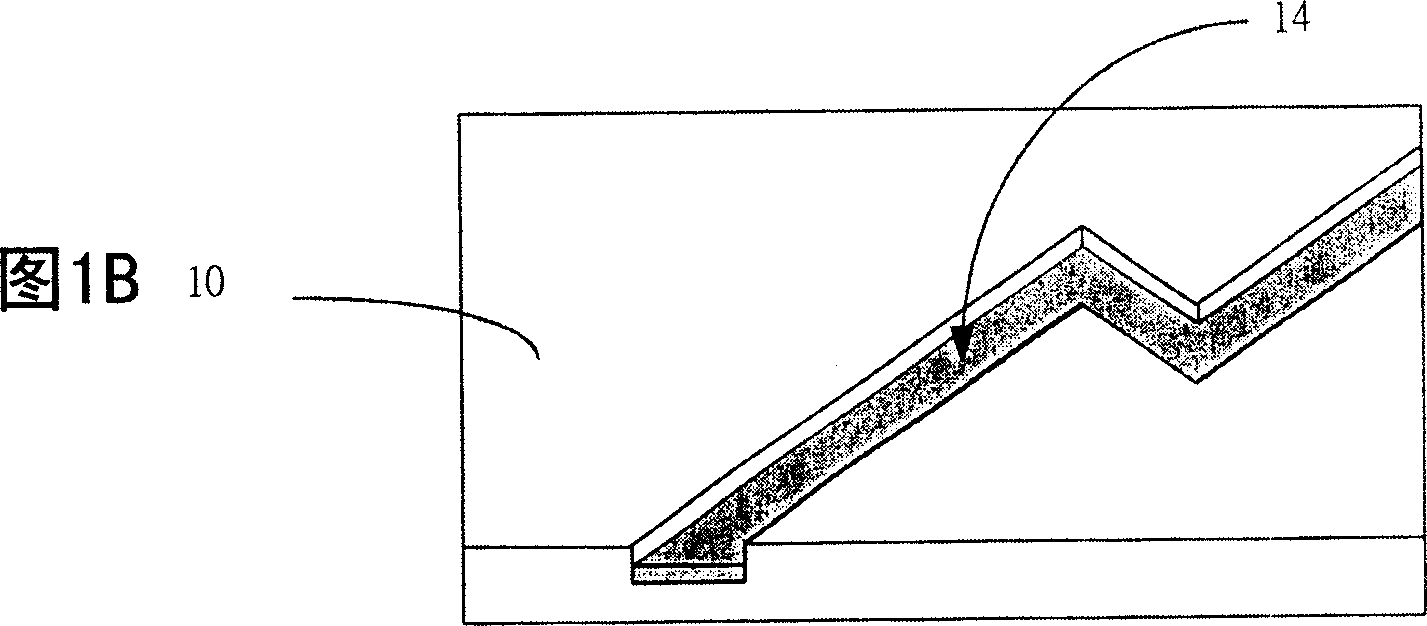

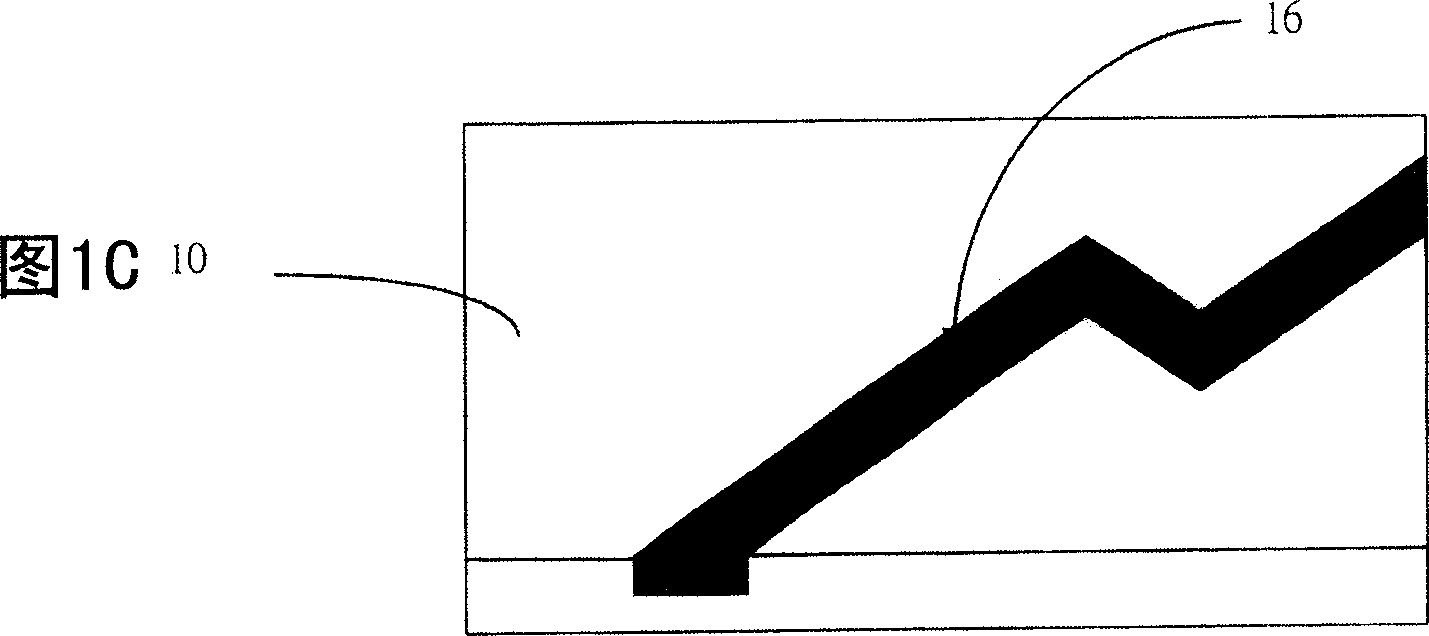

[0015] Please refer to FIGS. 1A-1C . FIGS. 1A-1C are schematic diagrams of a method for manufacturing a conductive circuit according to the present invention. Form the structure of the conductive circuit of the conductive colloid 16 of the present invention as shown in Figure 1C and mainly can be divided into three steps, namely form the groove 12 of the conductive circuit as shown in Figure 1A, form the groove 12 as shown in Figure 1B. The first colloid 14 forms the conductive circuit of the conductive colloid 16 shown in FIG. 1C.

[0016] The conductive colloid 16 is formed by the first colloid 14 and the second colloid (not shown) that will undergo chemical changes with the first colloid 14, and this chemical change makes the second colloid, which is originally in a colloidal state, and the first colloid 14. Form a solid conductive colloid 16 in the groove 12 of the conductive circuit. The first colloid 14 and the second colloid used in the present invention may be Electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com