Flat type discharge lamp and lighting device

A discharge lamp, a planar technology, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of insufficient voltage at the front end of the lamp, decrease in lamp brightness, and decrease in lamp quality, and achieve reduction Effects of heat loss, resistance value reduction, and voltage drop suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0048] Fig. 1 is a perspective view showing a flat discharge lamp according to a first embodiment of the present invention.

[0049]The front substrate 1 and the back substrate 2 made of light-transmitting glass plates are arranged facing each other at a substantially constant interval, and the edge portions of the two glass plates are bonded by the side walls 3 with the sealing glass 4 to form a planar substrate. the discharge container. In addition, the planar container can also adopt a structure in which any one of the glass substrates is formed in a basin shape, thereby omitting the side wall, or instead of using sealing glass, the edge part of the glass substrate is heated to melt the glass and bonded. up structure.

[0050] Inside the planar discharge vessel, as a discharge medium, one or a mixture of two or more of mercury vapor, xenon, krypton, argon, neon, and helium is filled at an inflation pressure of several kPa to hundreds of kPa.

[0051] Fluorescent layers 5a...

no. 2 Embodiment

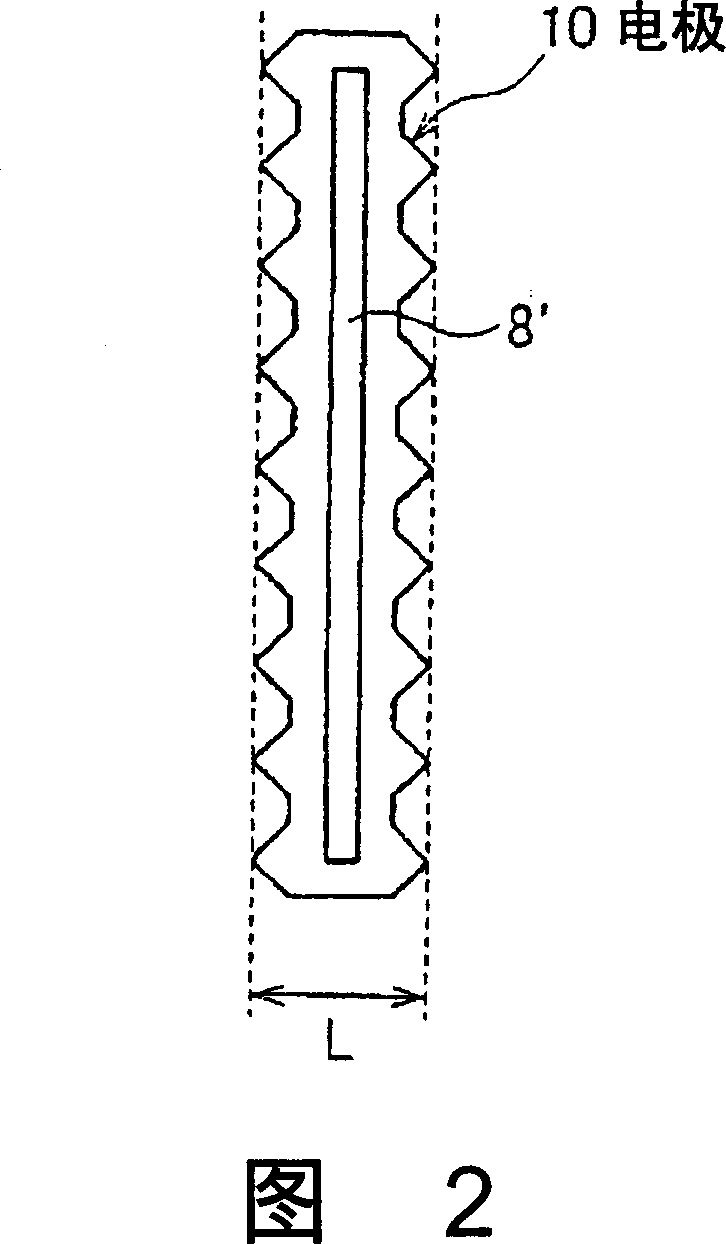

[0060] 15 to 17 respectively show a perspective view, a plan view, and a cross-sectional view of a flat discharge lamp 20 according to a second embodiment of the present invention. In addition, FIG. 18 is a sectional view taken along line A-A' in FIG. 16 . Between the front substrate 1 and the rear substrate 2, a spacer 8 is formed in a hollow cylindrical shape such as a cylindrical shape or a quadrangular cylindrical shape to prevent collapse due to atmospheric pressure. Utilize front substrate 1 and back substrate 2 and side wall 3 (though not shown in figure, but be formed on the 4 sides of front substrate 1 and back substrate 2), keep the airtightness in the discharge vessel, at least fill the inside with mercury vapor or More than one inert gas is used as the discharge medium.

[0061] In addition, the airtightness of the interior of the hollow spacer 8 should also be maintained, and mercury vapor or more than one inert gas should also be filled. Here, the inert gas in ...

no. 3 Embodiment

[0064] 19 and 20 are perspective views of a flat discharge lamp 20 according to a third embodiment of the present invention, and are perspective views of the flat discharge lamp 20 viewed from the rear substrate 2 and the front substrate 1, respectively.

[0065] In this embodiment, the front substrate 1 made of a light-transmitting glass plate is thermoformed to have a concavo-convex cross-section, and the convex portion 1b is in contact with the back substrate 2 also made of a light-transmitting glass plate. function as a spacer. That is, between the front substrate 1 and the rear substrate 2 , a plurality of elongated discharge spaces are formed by full-shaped recesses. Then, elongated strip-shaped external electrodes 6 and 7 are formed on the outer surface of rear substrate 2 . Then, the structure is the same as that of the first embodiment, and the bonding surface between the convex portion 1b of the front substrate 1 and the rear substrate 2 is provided within the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com