Tapered roller bearing

A technology of tapered rollers and bearings, applied in the field of tapered roller bearings, can solve problems such as adding cages, and achieve the effect of preventing surface starting wear and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

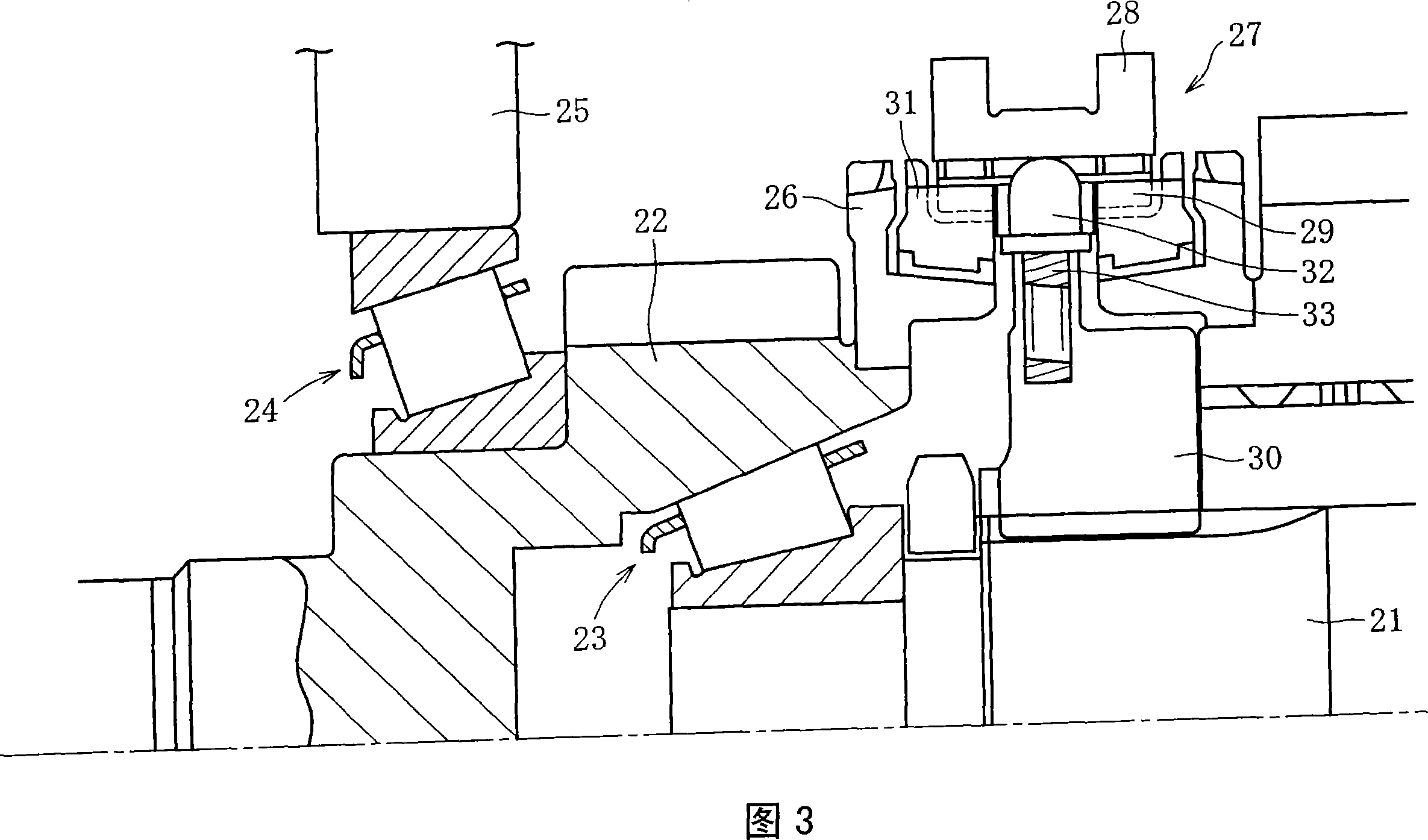

[0036] The transmission (main transmission unit) of an automobile is roughly classified into a manual type and an automatic type. In addition, they can also be classified according to the drive system of the vehicle: front-wheel drive (FWD) transmission differential, rear-wheel drive (RWD) gearbox and four-wheel drive (4WD) transfer case (auxiliary transmission unit ). They are used to shift the drive power from the engine and transmit it to the drive shaft, etc.

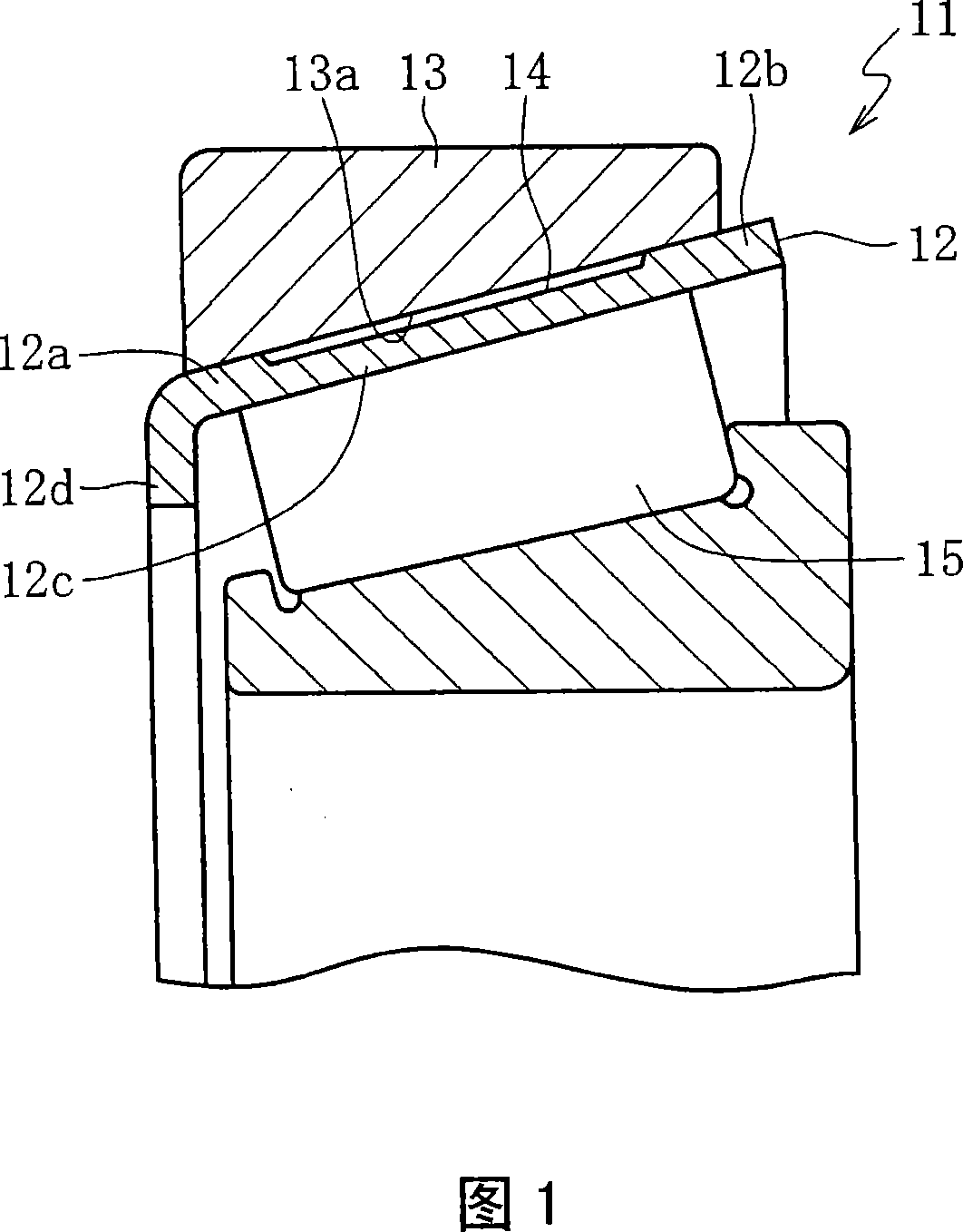

[0037]Fig. 3 shows an example of the structure of an automobile gearbox. This gearbox is of the synchromesh type, where in the same figure, the left side is the engine side and the right side is the drive wheel side. A tapered roller bearing 23 is inserted between the main shaft 21 and the main drive gear 22 . In this example, the inner periphery of the main drive gear 22 is directly formed with the outer ring raceway surface of the corresponding tapered roller bearing 23 . The main drive gear 22 is supported by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com