A flow field plate and fuel cell stack containing the same

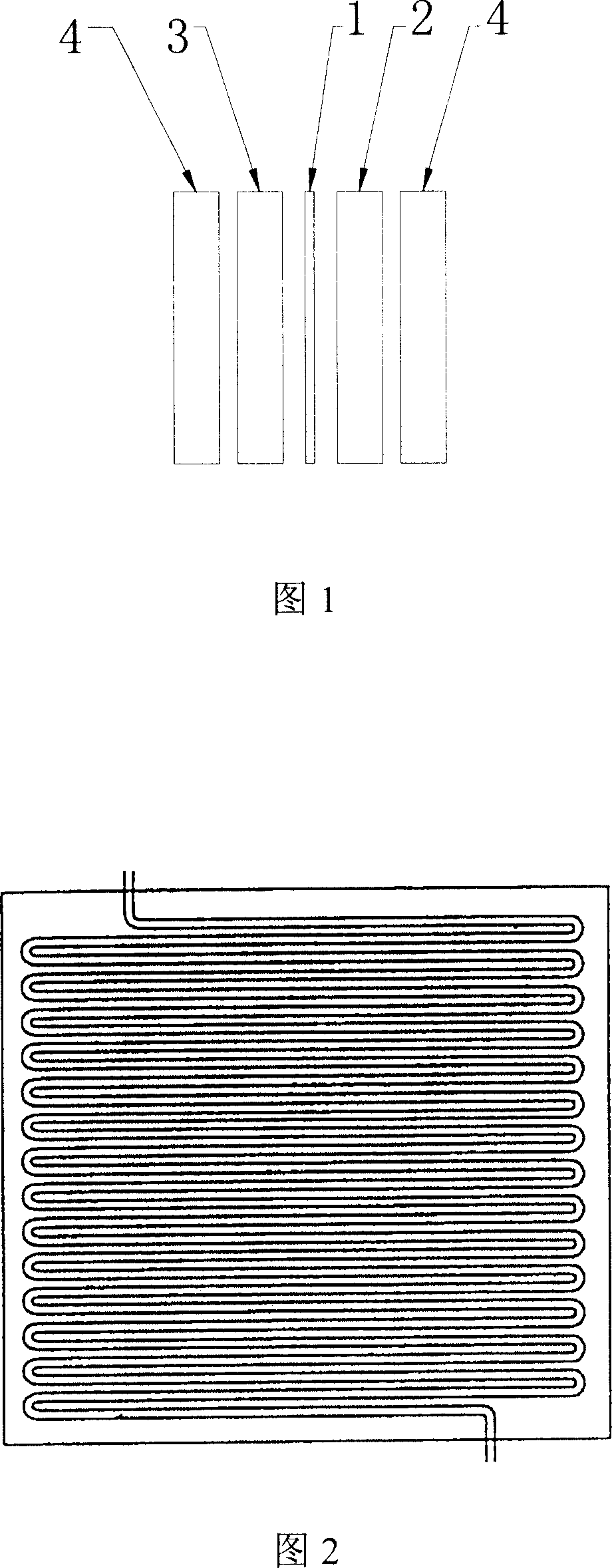

A fuel cell stack and flow field plate technology, which is applied to fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of reactant diffusion, reaction product discharge, etc., and achieve short process, high utilization rate, effective The effect of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

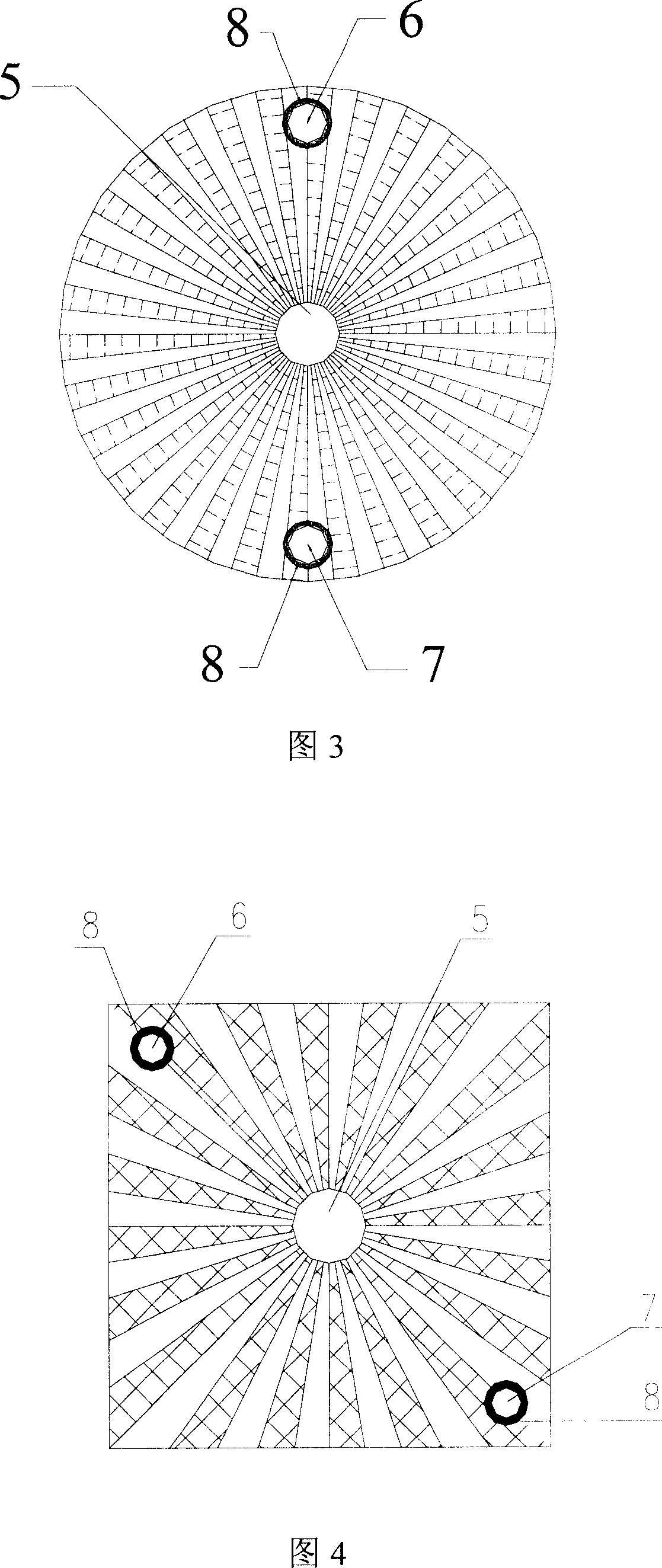

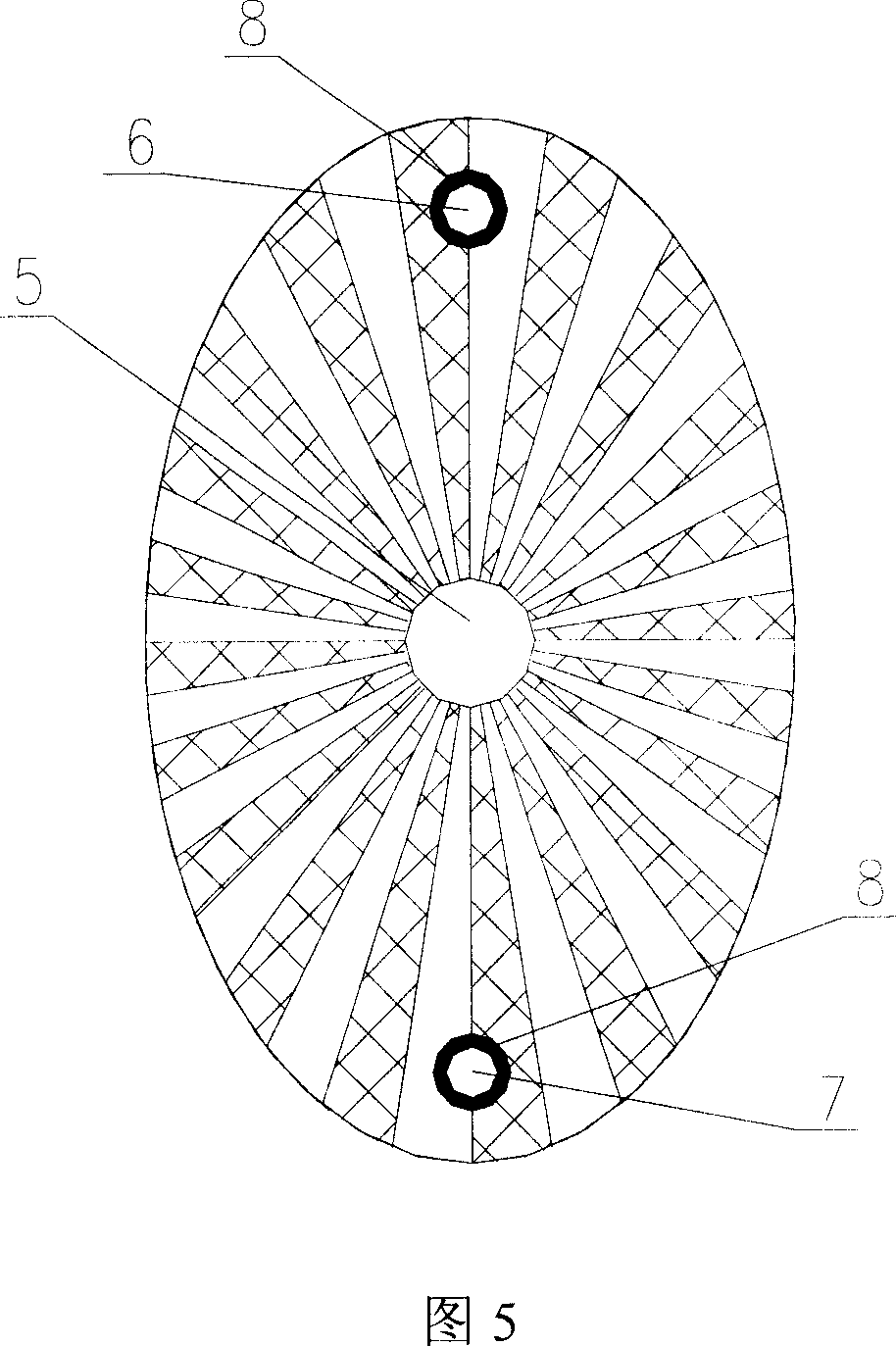

[0026] The flow field plate provided by the present invention includes a central hole 5 located at the center of the flow field plate, an inflow hole 6 and an outflow hole 7 located at two positions close to the edge of the flow field plate, preferably, the inflow hole 6 and the outflow hole 7 The position is symmetrical with respect to the central hole 5 . One side of the flow field plate includes flow guide grooves diverging from the central hole 5 to the surroundings.

[0027] Wherein, the flow field plate can be made of graphite or metal materials, such as titanium, stainless steel, gold, silver or copper, and other materials with good electrical conductivity. The flow field plate can be in various shapes, such as circular, elliptical or polygonal, preferably circular, rectangular or elliptical. The central hole 5, the inflow hole 6 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com