A quadrate lithium ion cell electrode core and its battery

A technology of lithium-ion batteries and pole cores, which is applied in non-aqueous electrolyte battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of fast capacity decay, poor cycle performance, slow capacity decay, etc., and achieve improved cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A conventional positive electrode sheet is prepared by coating a slurry containing positive active material and a binder on a wide-width electrode sheet, drying, rolling and slitting to obtain the positive electrode sheet. Wherein, the solvent containing positive electrode active material and binder slurry is selected from conventional solvents, such as N-methylpyrrolidone (NMP), dimethylformamide (DMF), etc., and the amount of solvent can make the slurry What is necessary is just to apply to the said current collector. Generally, the solvent is used in an amount of 40-90% by weight of the content of the positive active material in the slurry, preferably 50-85% by weight. The drying temperature is generally 50-160°C, preferably 80-150°C. Rolling is to roll the commercially available wide-width pole piece into the required thickness of the positive pole piece, which can vary in a wide range according to the needs of various batteries. The purpose of slitting is to cut ...

Embodiment 1

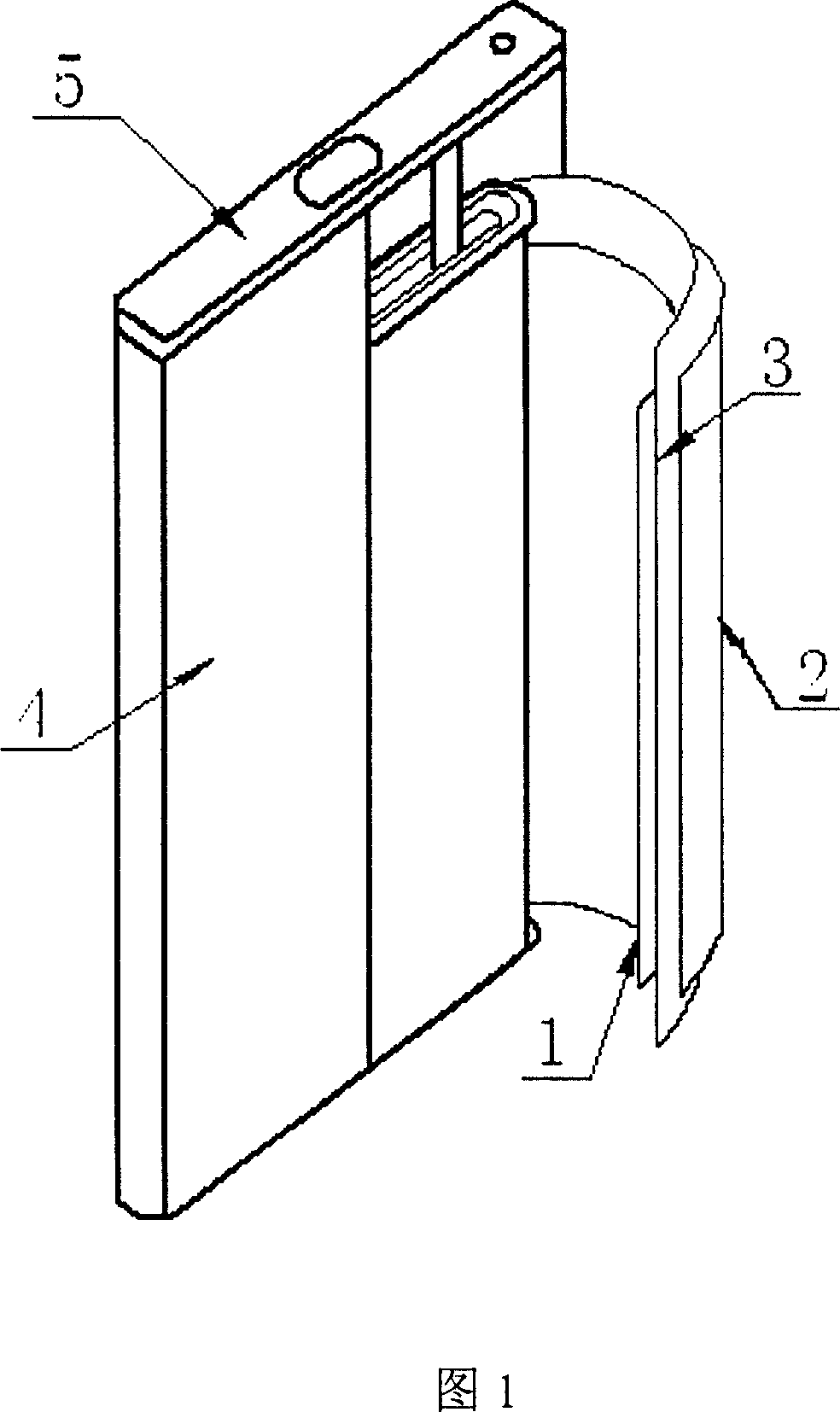

[0063] Design and make the square battery of the present invention, namely thickness is 4.5 millimeters, and width is 34 millimeters, and height is the square aluminum case lithium ion secondary battery of 50 millimeters.

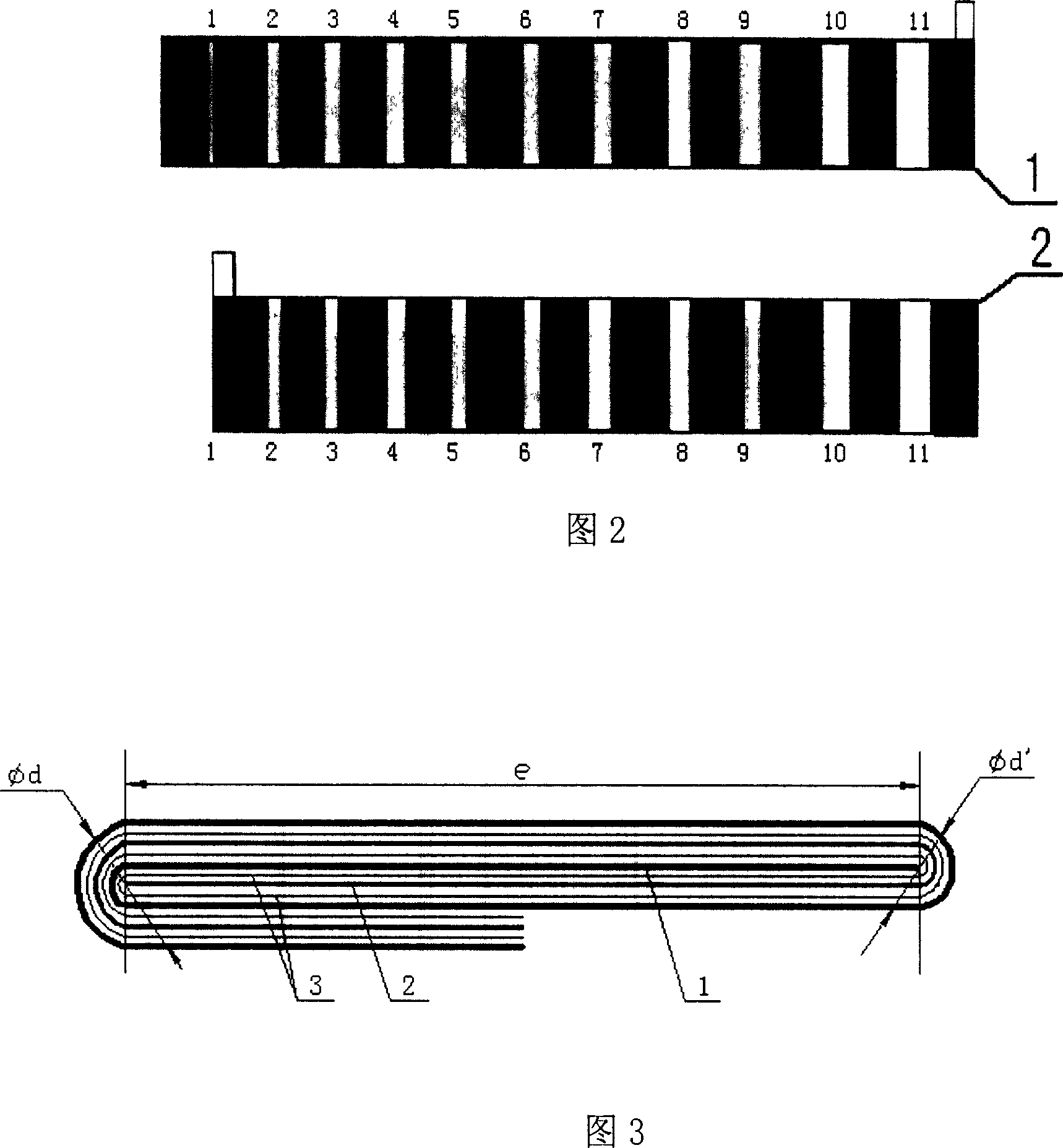

[0064] (1) Preparation of positive electrode sheet 1

[0065] 100 parts by weight of the positive electrode active material LiCoO 2 , 5 parts by weight of conductive agent acetylene black, and 5 parts by weight of binder PVDF are added to 50 parts by weight of NMP and mixed evenly, and then evenly coated on an aluminum foil with a thickness of 0.02 mm, and then coated evenly Scrape off the positive electrode material at the position not coated with the active material, put it into a vacuum oven, bake and dry it at 120°C, and then press and cut it into positive electrode sheets of 374×44×0.135 mm. The positive active material LiCoO on the positive electrode sheet 2 The content is 6.4 grams.

[0066] (2) Preparation of negative electrode sheet 2

[0067] ...

Embodiment 2

[0081] The inner and outer rings of the positive electrode 1 and the negative electrode 2 are not coated with active materials at the positions where the positive electrode 1 and the negative electrode 2 are curved to form a semicircle. The rest of the manufacturing process of the battery is the same as that of the battery in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com