Magnetic flowing deformation elastomer frequency shift type attenuator and control method

A magnetorheological elastomer and vibration absorber technology, which is applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of narrow control frequency band, insignificant influence of vibration absorber characteristics, and high energy consumption, etc., to achieve vibration reduction frequency Wide bandwidth, easy control method, and high system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

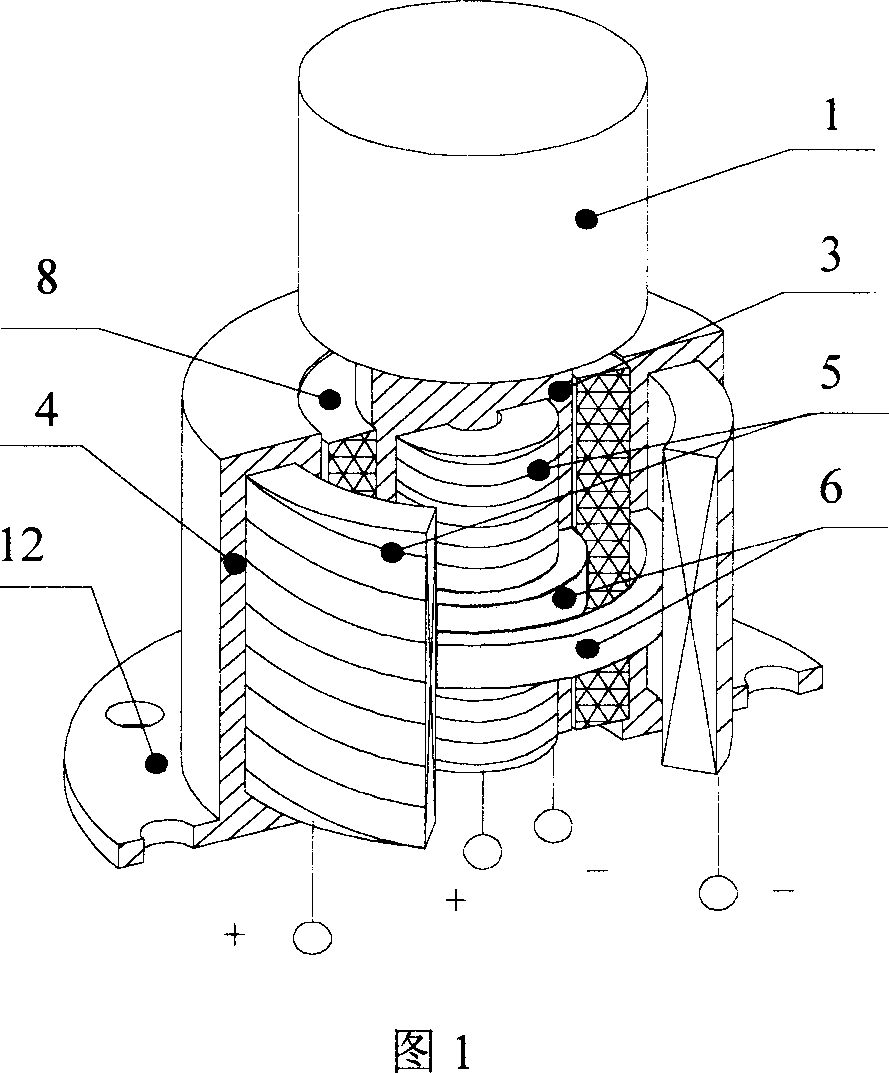

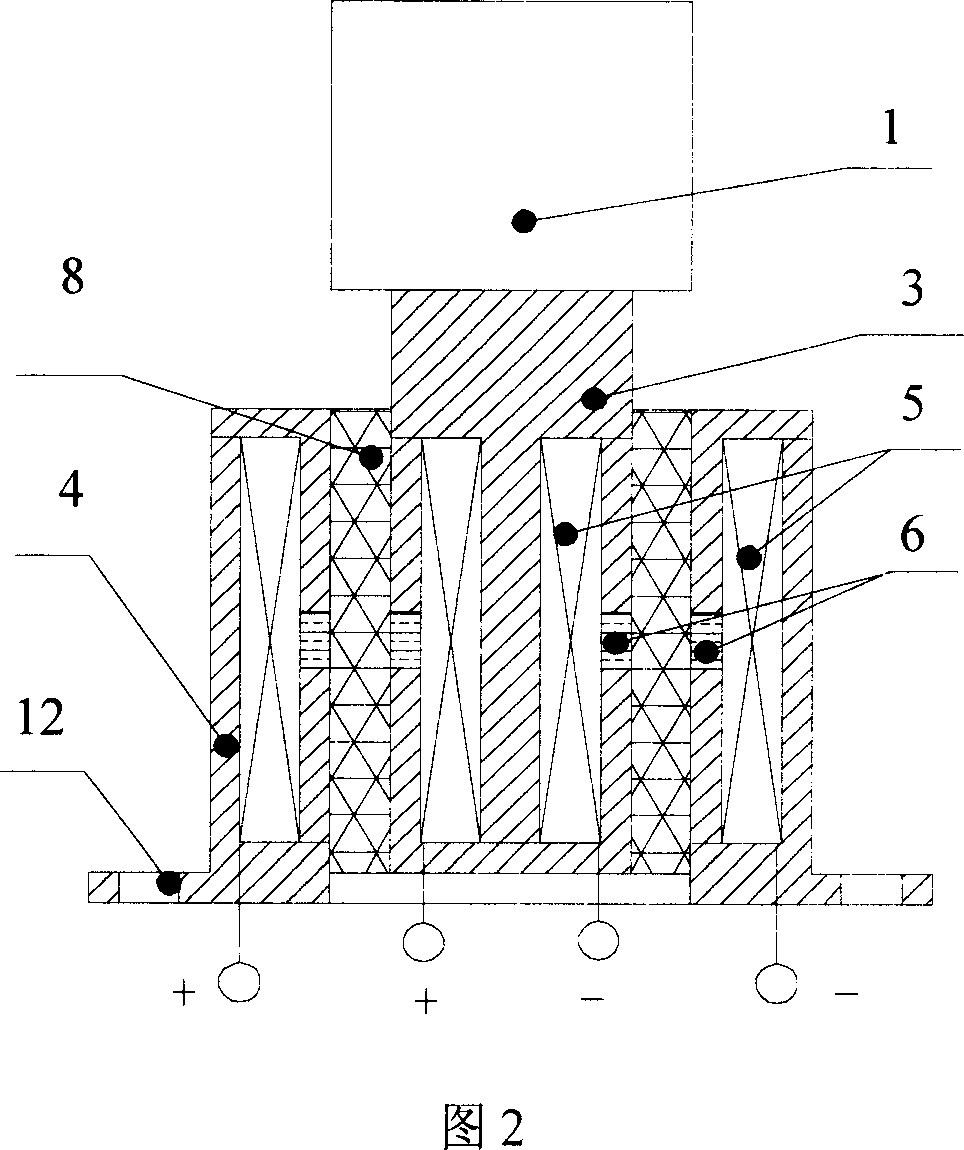

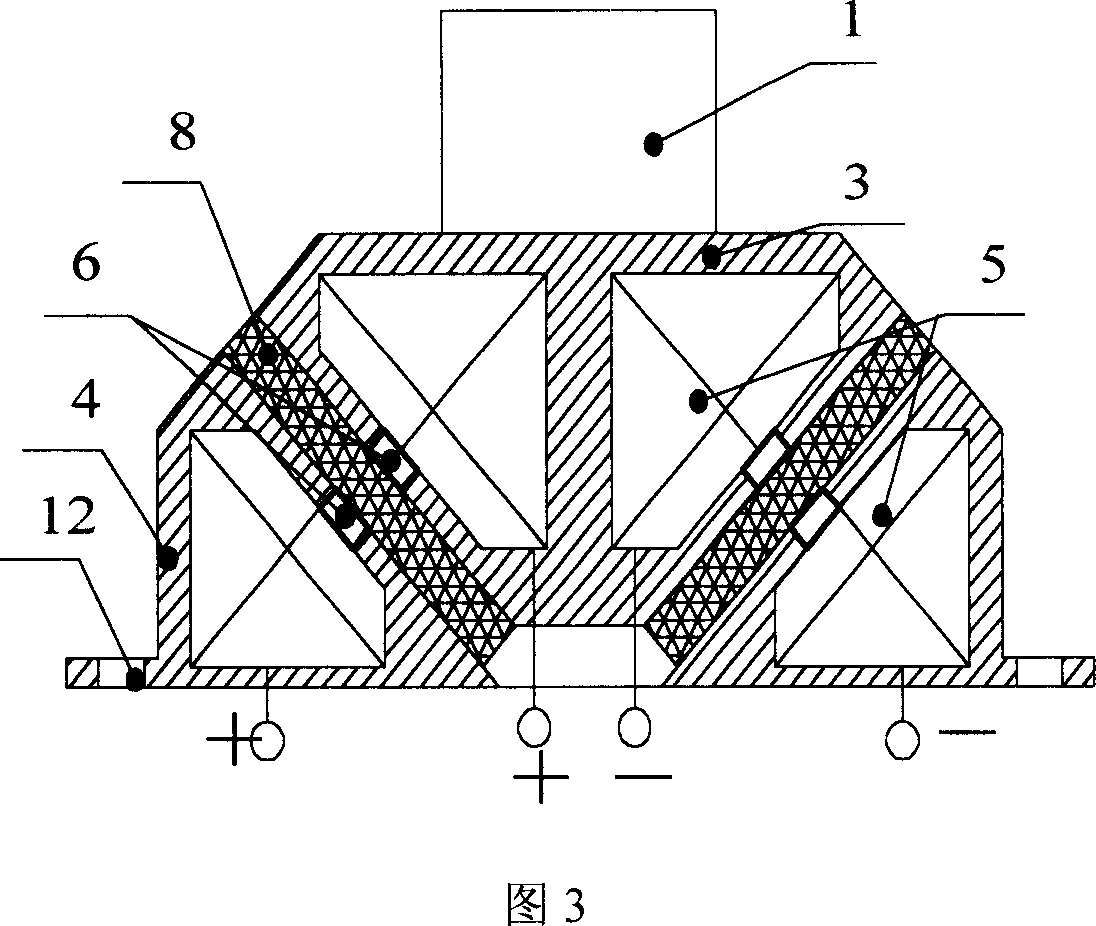

[0029] Embodiment 1: The shear-type magnetorheological elastomer frequency-shifting vibration absorber shown in Figure 1 and Figure 2 is composed of an inner sleeve 3 and an outer sleeve 4, a coil 5, a magnetic isolation ring 6, a magnetorheological Elastomer 8 and vibration-absorbing mass 1, base 12 constitute, sleeve and base are made of electrical pure iron, magnetic isolation ring is made of brass, and vibration-absorbing mass is also made of brass. The outer sleeve 4 is cylindrical, and the cross-sectional shape of its half is C-shaped, and the C-shaped opening faces inward, that is, there is a cavity inside the sleeve and an opening on the inner side wall. The coil 5 is just placed in the cavity, and the C-shaped opening on the inner side wall The opening is closed with an annular magnetic isolation ring 6, and the inner sleeve 3 is columnar or cylindrical (that is, there may be a longitudinal through hole or no longitudinal through hole at its axis), and the cross-sectio...

Embodiment 2

[0036] Embodiment 2: The tension-compression type magnetorheological elastomer frequency-shifting vibration absorber shown in Figure 4 consists of a U-shaped iron core 2, a magnetorheological elastomer 8, an armature 9, a vibration-absorbing mass 1, a base 12 and The coil 5 is formed, wherein the U-shaped iron core 2 and the armature 9 are made of industrial pure iron, the coil 5 is wound around the bottom of the U-shaped iron core, and the armature 9 is horizontally placed on the upper part, and the armature is strip-shaped. A sheet magnetorheological elastomer 8 is fixed between the armature 9 and the U-shaped iron core 2, and the vibration-absorbing mass 1 is fixed on the armature 9 with threads. The screw holes on the base 12 are fixed to the damping object, and other control methods are the same as in the first embodiment. It works in the state of tension and compression, which can eliminate the linear vibration consistent with the vibration direction of the vibration dam...

Embodiment 3

[0037] Embodiment 3: The torsion-bending composite magnetorheological elastomer frequency-shifting vibration absorber as shown in Figure 5 consists of an upper plate 10, a lower plate 11, a coil 5, a columnar iron core 7, a magnetorheological elastomer 8, and a base The seat 12 and the vibration-absorbing mass 1 are formed, the upper plate 10, the lower plate 11 and the columnar iron core 7 are made of industrial pure iron, the base 12 is made of aluminum, the columnar iron core 7 is wound around the coil 5, and the columnar iron core 7 is up and down. Fix one end of the upper plate 10 and the lower plate 11 or any part in the middle with threads, and the remaining parts between the two plates are fixed with a block-shaped magnetorheological elastomer 8, the upper plate 10, the lower plate 11, the magnetorheological The elastic body 8 forms a sandwich biscuit-like sandwich beam as a whole and welds one end of it to the base to form a cantilever beam. The other end of the cantil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com