Blocking and antiunloading nut

A nut and anti-unloading technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of reduced performance, cumbersome assembly, uncomfortable tightening, etc., and achieve the effects of reducing friction, good anti-theft effect, and convenient screwing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

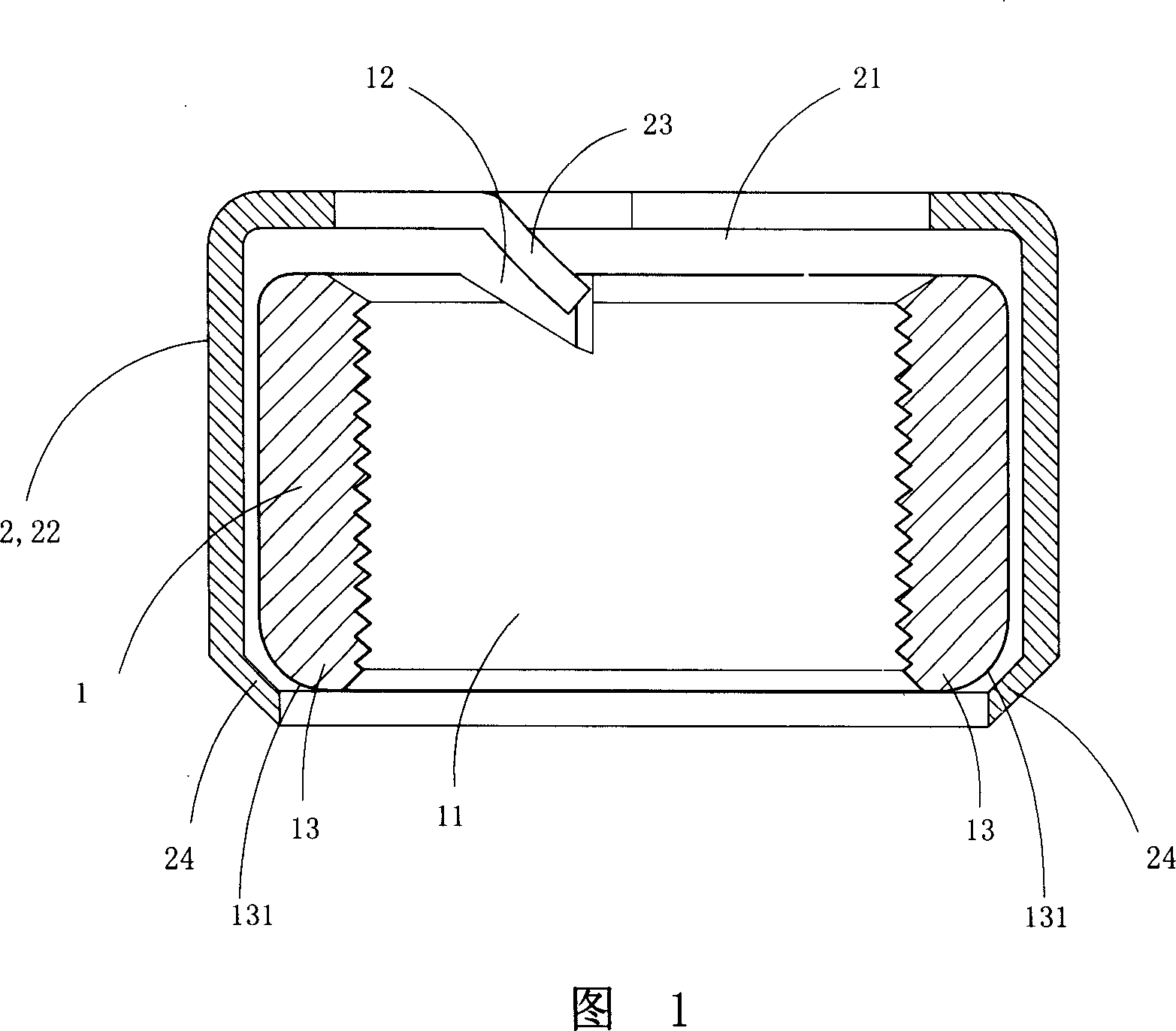

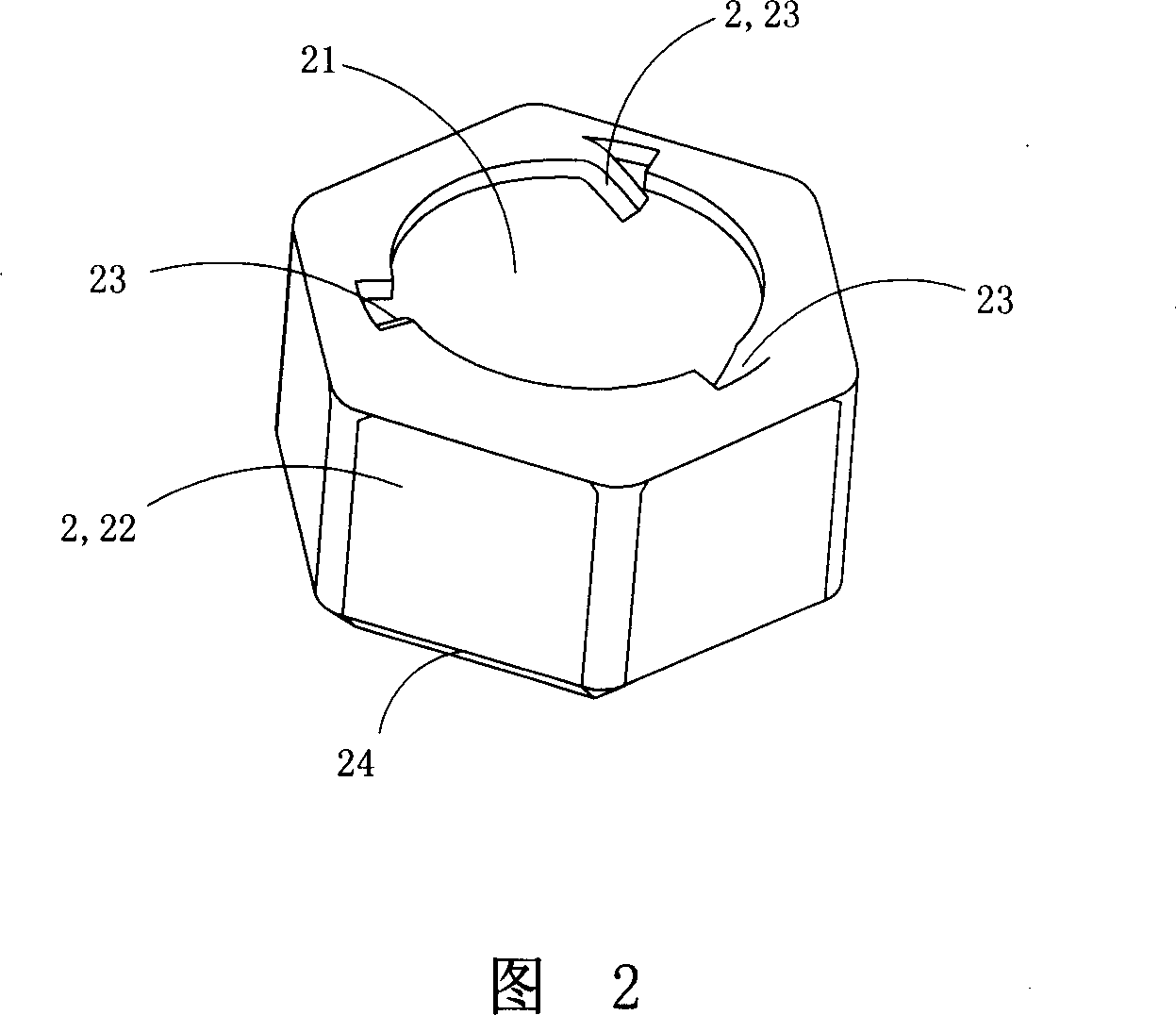

[0025] See Figures 1 to 6, this embodiment is an anti-loosening and anti-unloading nut, which includes a round nut body 1 and a hexagonal outer cover 2; the center of the nut body 1 is provided with an inner screw hole 11, so that The upper surface of the nut body 1 is provided with three fastening grooves 12, and the fastening grooves 12 are surrounded by a downwardly inclined guide surface 121 and a blocking surface 122; in this embodiment, the guide surface 121 It is an inclined surface, and the blocking surface 122 is a vertical surface; the lower part of the nut body 1 is provided with a supporting portion 13 having an arc-shaped surface 131 . The supporting part 13 with the arc surface can reduce the friction force between the nut body and the outer cover when fastening and screwing in, making the screwing in more convenient and easy.

[0026] The center of the outer cover 2 is provided with a circular cavity 21, the outer wall of the outer cover 2 is provided with a hex...

Embodiment 2

[0033] See Figure 8, the anti-loosening and anti-unloading nut of this embodiment is basically the same as that of Embodiment 1, the difference is that: the guide surface 121 is a downwardly inclined arc surface, and the blocking surface 122 is a slightly oriented As for the downward inclined surface, the inclination direction of the blocking surface 122 is the same as the inclination direction of the guiding surface 121 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com