Laminated flowing cooling water side-jetting sweeping system after high-strength low-alloy steel being rolled

A low-alloy steel, laminar cooling device technology, used in cooling bed, metal rolling, metal rolling and other directions, can solve the problems of poor steel plate, difficult to clean the shape of the plate, and achieve good shape, The effect of excellent plate shape and increased cooling water volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

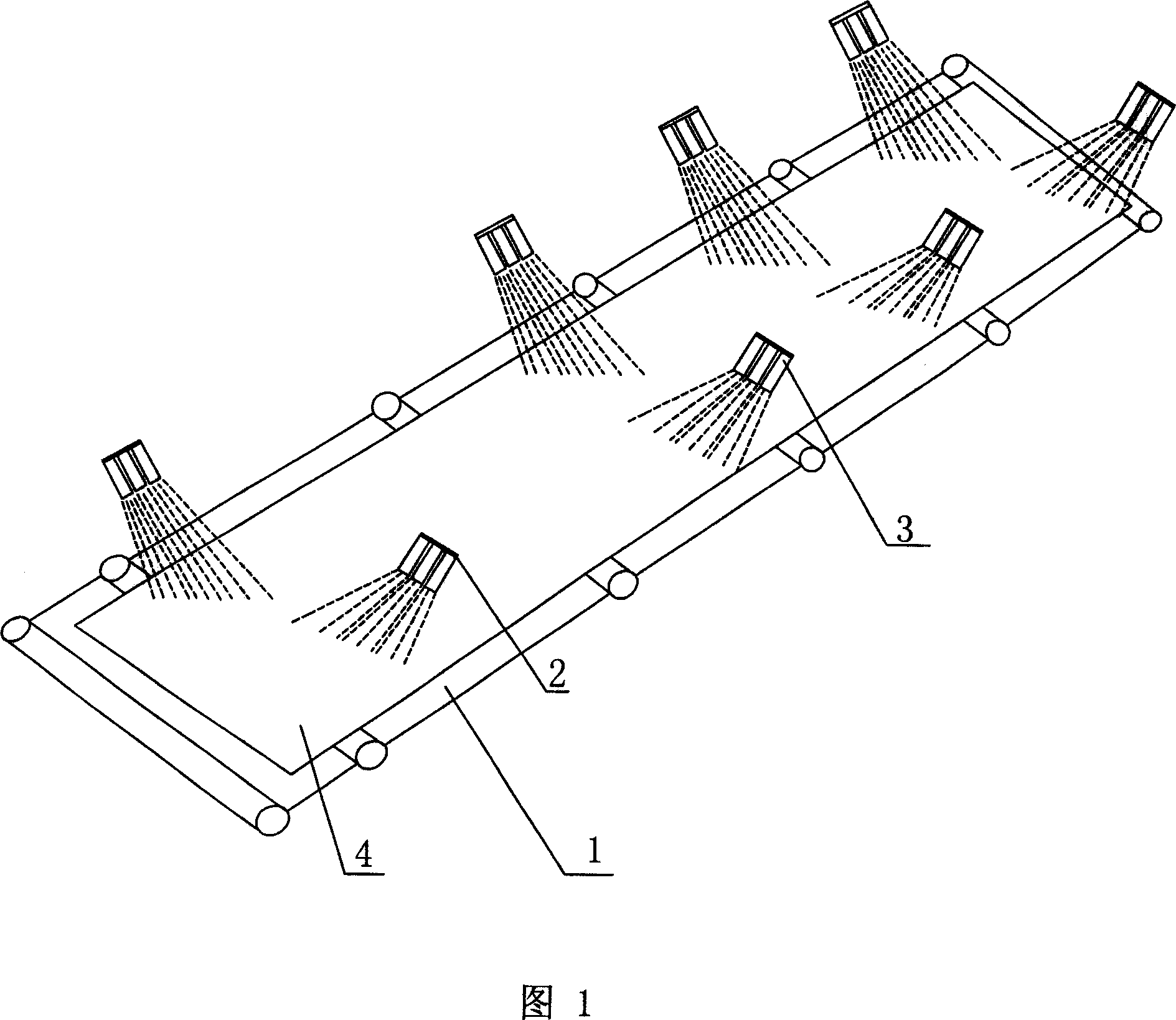

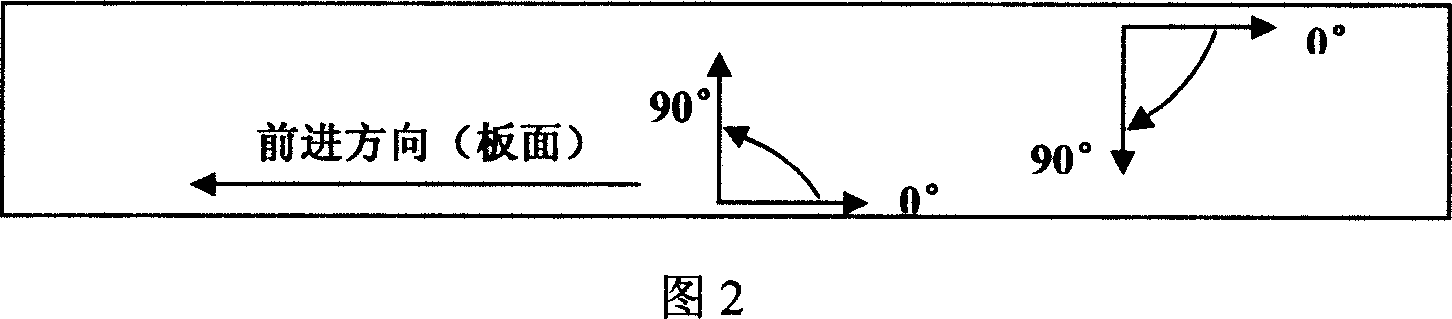

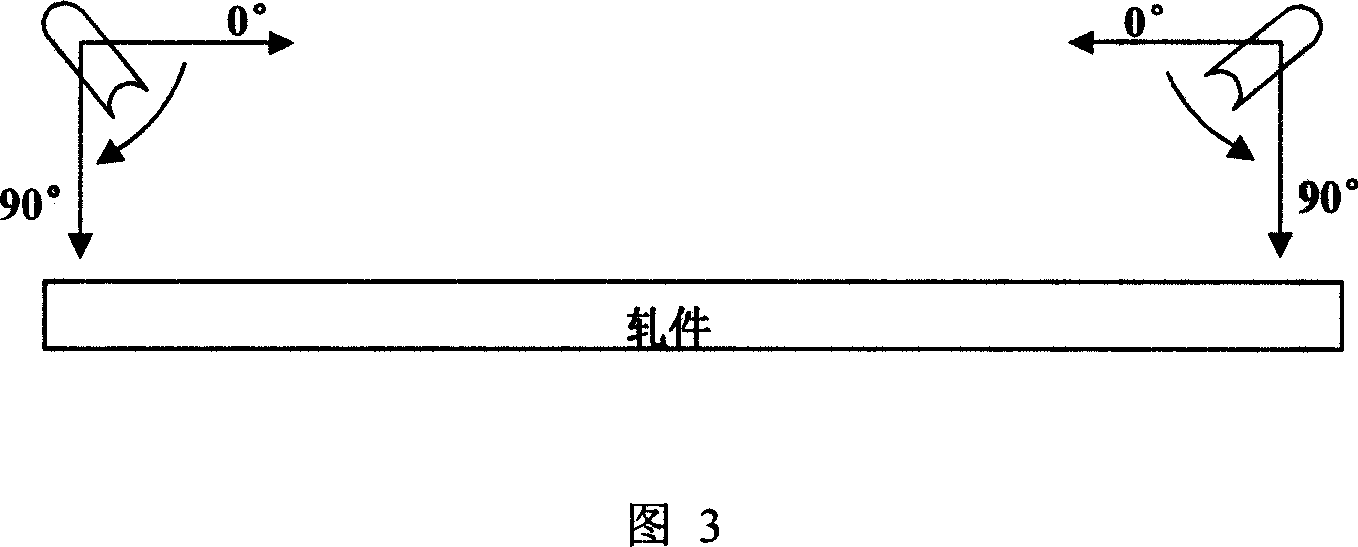

[0022] The structure of this embodiment is shown in FIG. 4 . This embodiment is provided with four groups of side spray devices 2 , and each group of side spray devices 2 is provided with three nozzles 3 . The water pressure of the side spray device 2 is selected between 10-50MPa, and the diameter of the nozzle 3 is selected between 20-100mm. The angle between the axis of the nozzle 3 and the rolling direction is 45°, and the angle between the axis of the nozzle 3 and the horizontal plane of the conveying roller table 1 is 45°. The side spray device 2 is provided with a group on both sides of the conveying roller table 1 before the steel plate 4 enters the laminar flow cooling device, so that the cooling water can be blocked in the laminar flow cooling area to prevent the loss of cooling water, so that the laminar flow cooling can reach Great cooling effect. The side spray device 2 is provided with a group between the strong cooling section and the intermediate cooling sectio...

Embodiment 2

[0024] The structure of this embodiment is shown in FIG. 5 . This embodiment is provided with four groups of side spray devices 2 , and each group of side spray devices 2 is provided with four nozzles 3 . The water pressure of side spray device 2 is 40MPa, and the diameter of nozzle 3 is 80 millimeters. The angle between the axis of the nozzle 3 and the rolling direction is 60°, and the angle between the axis of the nozzle 3 and the horizontal plane of the conveying roller table 1 is 60°. The side spray device 2 is provided with two groups on both sides of the conveying roller table 1 before the steel plate 4 enters the laminar flow cooling device, so that the cooling water can be blocked in the laminar flow cooling area to prevent the loss of cooling water, so that the laminar flow cooling achieve a good cooling effect. The side spray device 2 is provided with a group between the strong cooling section and the intermediate cooling section of the laminar flow cooling device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com