Method for continuously thermal decomposing waste tire using gas burning kiln

A waste tire and pyrolysis technology, which is applied in the field of solid waste, especially waste tire treatment, can solve the problems of pollution, high cost, and small processing capacity, and achieve the effects of broad promotion prospects, high operating flexibility, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

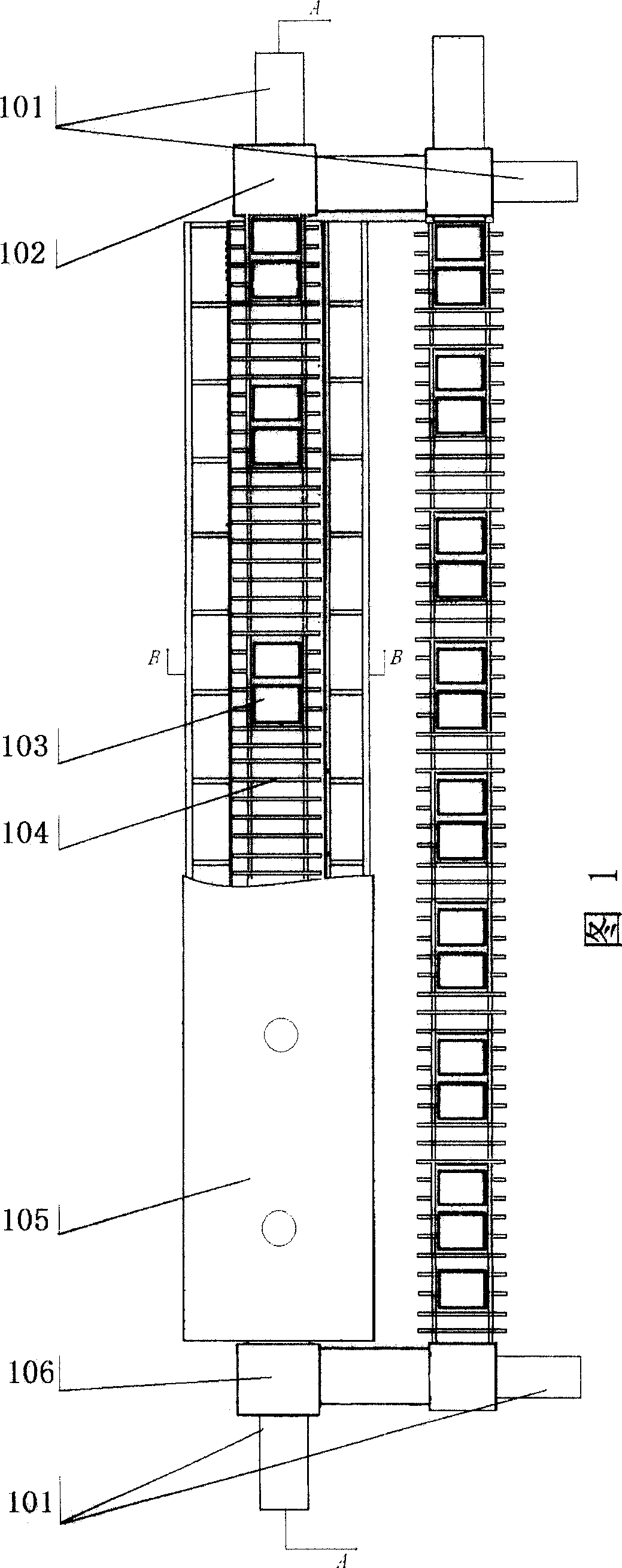

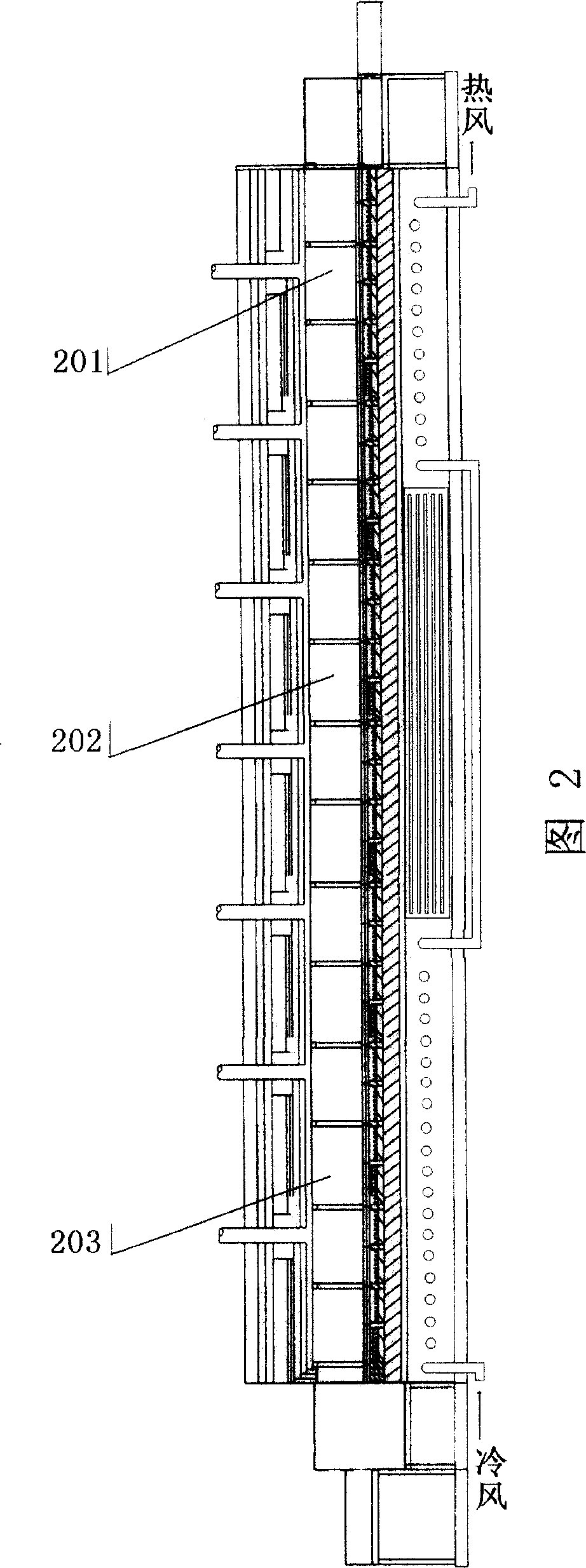

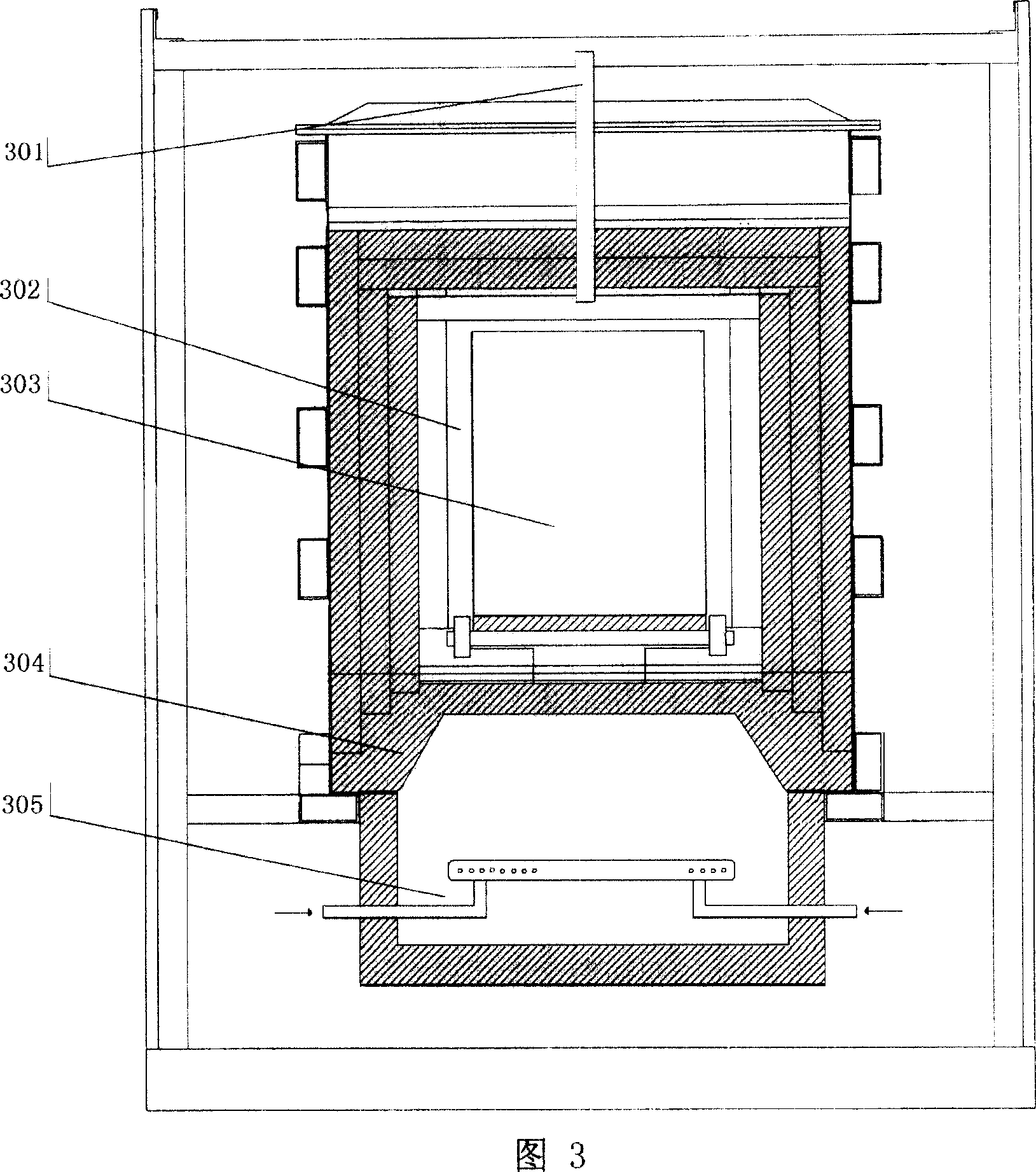

[0041]Ordinary car waste tires are cleaned and dried, put into the pyrolysis container (303), add catalyst mica at the same time, place on the push plate (103), and are fed by the hydraulic pusher (101) through the sealed chamber (102) Push it into the furnace body (105); in the state of slight negative pressure, the pyrolysis container moves at a constant speed on the roller bar (104) under the push of the subsequent push plate, and is preheated by the preheating section (201) ( 200°C), pyrolysis section (202) pyrolysis (450°C), cooling section (203) after cooling (100°C), the residence time is 3.5h, and the hydraulic pusher (101) pushes out the discharge sealed cabin (106) . The gas production rate is 17%, of which 85% is used for kiln heating, the oil production rate is 45%, the pyrolysis carbon production rate is 38%, and the discharge temperature is 90°C.

Embodiment 2

[0043] Ordinary car waste tires are cleaned and dried, put into the pyrolysis container (303), add catalyst mica at the same time, place on the push plate (103), and are fed by the hydraulic pusher (101) through the sealed chamber (102) Push it into the furnace body (105); in the state of slight negative pressure, the pyrolysis container moves at a constant speed on the roller bar (104) under the push of the subsequent push plate, and is preheated by the preheating section (201) ( 250°C), pyrolysis section (202) pyrolysis (550°C), cooling section (203) cooling (100°C), the residence time is 3.5h, and the hydraulic pusher (101) pushes out the discharge sealed cabin (106) . The gas production rate is 19%, of which 89% is used for kiln heating, the oil production rate is 49%, the pyrolysis carbon production rate is 34%, and the discharge temperature is 95°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com