Duprene rubber/vermicultie namo composite material and its preparing method

A nano-composite material and neoprene technology, applied in the field of neoprene/vermiculite nano-composite materials and their preparation, can solve problems such as unreported, and achieve the effects of wide application fields, improved elasticity, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: the preparation of neoprene / vermiculite nanocomposite

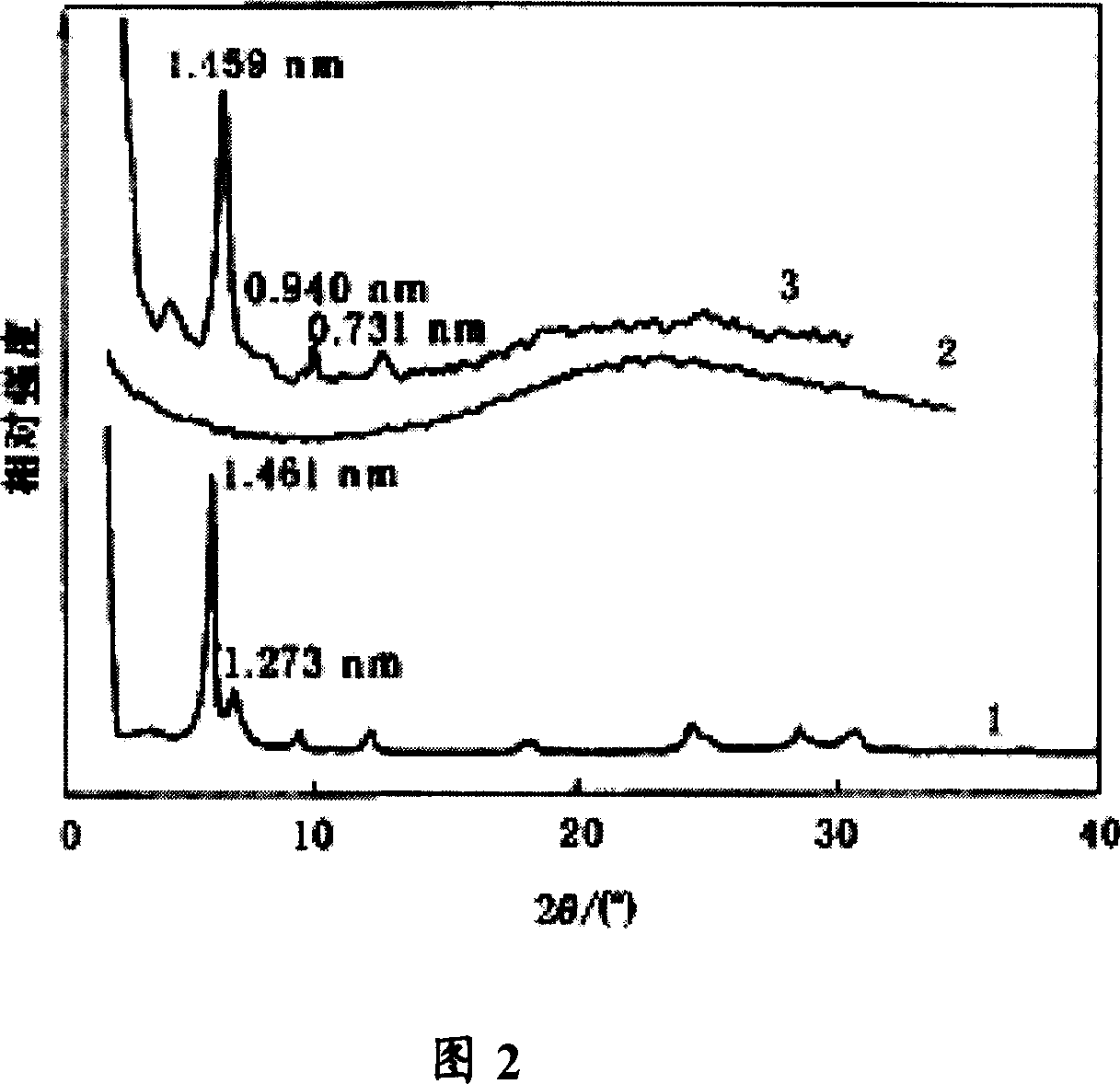

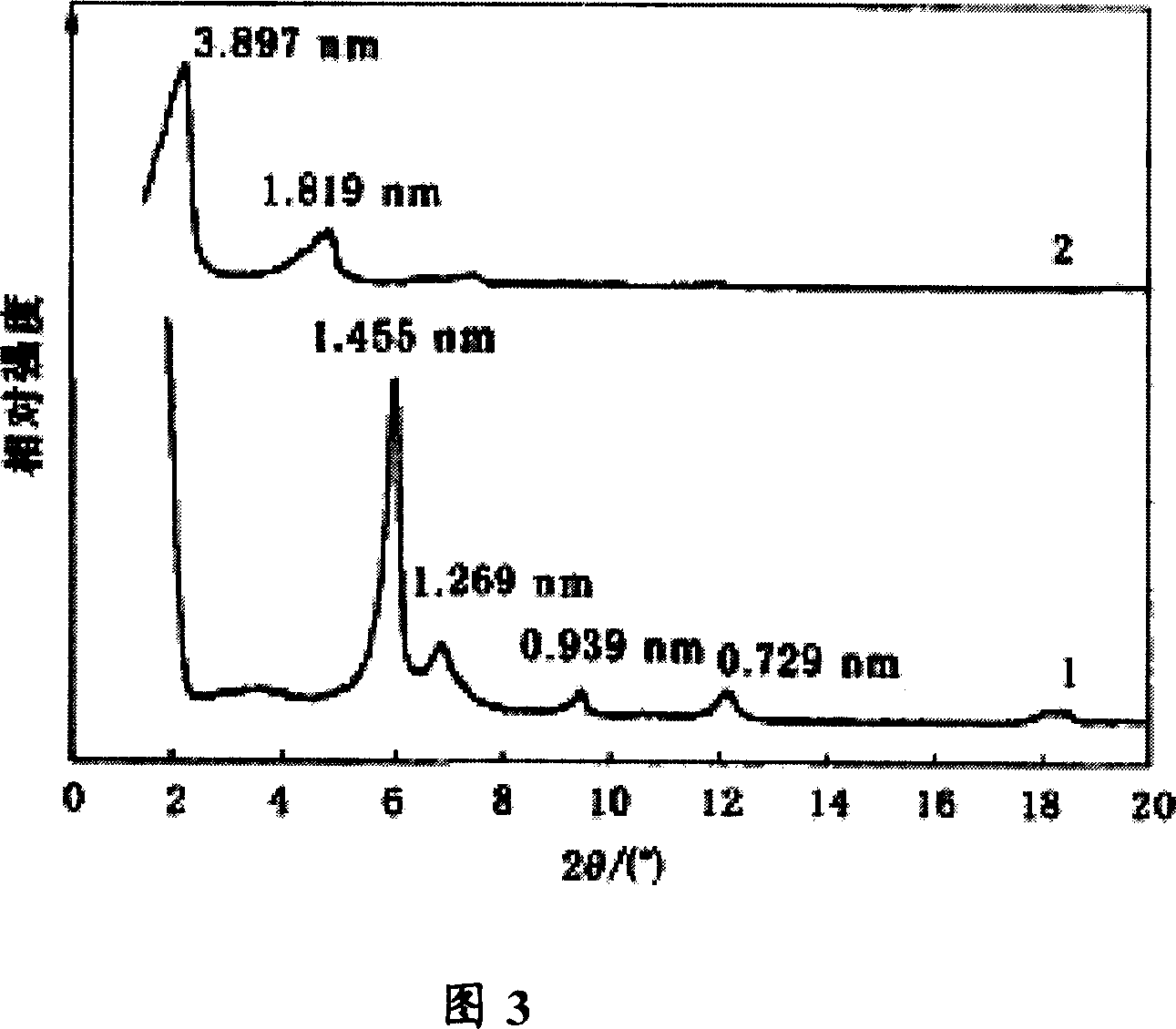

[0064] Add 6g of vermiculite with a cation exchange capacity of 105meq / 100g and a particle size of 200 mesh sieve into a three-necked bottle filled with 200ml of water, and evenly disperse in the solvent under electric stirring, and then add 3.4g of hexadecyl Trimethylammonium bromide, stir and heat up to 80°C, stir and react at 80°C for 2h, keep the temperature for 10 hours, cool to room temperature and centrifuge, wash the vermiculite sample fully with deionized water until 0.1mol / l AgNO 3 Check the solution until the supernatant does not appear precipitated. Dry the cleaned vermiculite sample in a drying oven at 70°C for several hours, and grind it until it passes through a 200-mesh sieve to obtain organic vermiculite.

[0065] Weigh 4g of the prepared organic vermiculite, soak it fully with 50ml tetrahydrofuran, and disperse it evenly in the solvent under magnetic stirring to obtain liquid A; d...

Embodiment 2

[0068] Embodiment 2: the preparation of neoprene / vermiculite nanocomposite

[0069] Add 6g of vermiculite with a cation exchange capacity of 90meq / 100g and a particle size of 200 mesh sieve into a three-necked bottle filled with 200ml of water, and disperse evenly in the solvent under electric stirring, and then add 2.88g of hexadecyl Trimethylammonium bromide, stir and heat up to 60-80°C, stir and react at 60-80°C for 2 hours, keep the temperature for 10 hours, cool to room temperature and centrifuge, fully wash the vermiculite sample with deionized water, until 0.1mol / l AgNO 3 Solution test supernatant until no precipitation occurs, dry the cleaned vermiculite sample in a drying oven at 70°C for several hours, and grind until it passes through a 200-mesh sieve to obtain organic vermiculite.

[0070] Weigh 5g of the obtained organic vermiculite and fully infiltrate it with 50ml xylene, and make it uniformly dispersed in the solvent under magnetic stirring to obtain liquid A;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com