Lifting mechanism of physical gas-phase deposition

A technology of physical vapor deposition and lifting mechanism, which is applied in the field of lifting mechanism, can solve the problem that the charge cannot be released, and achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

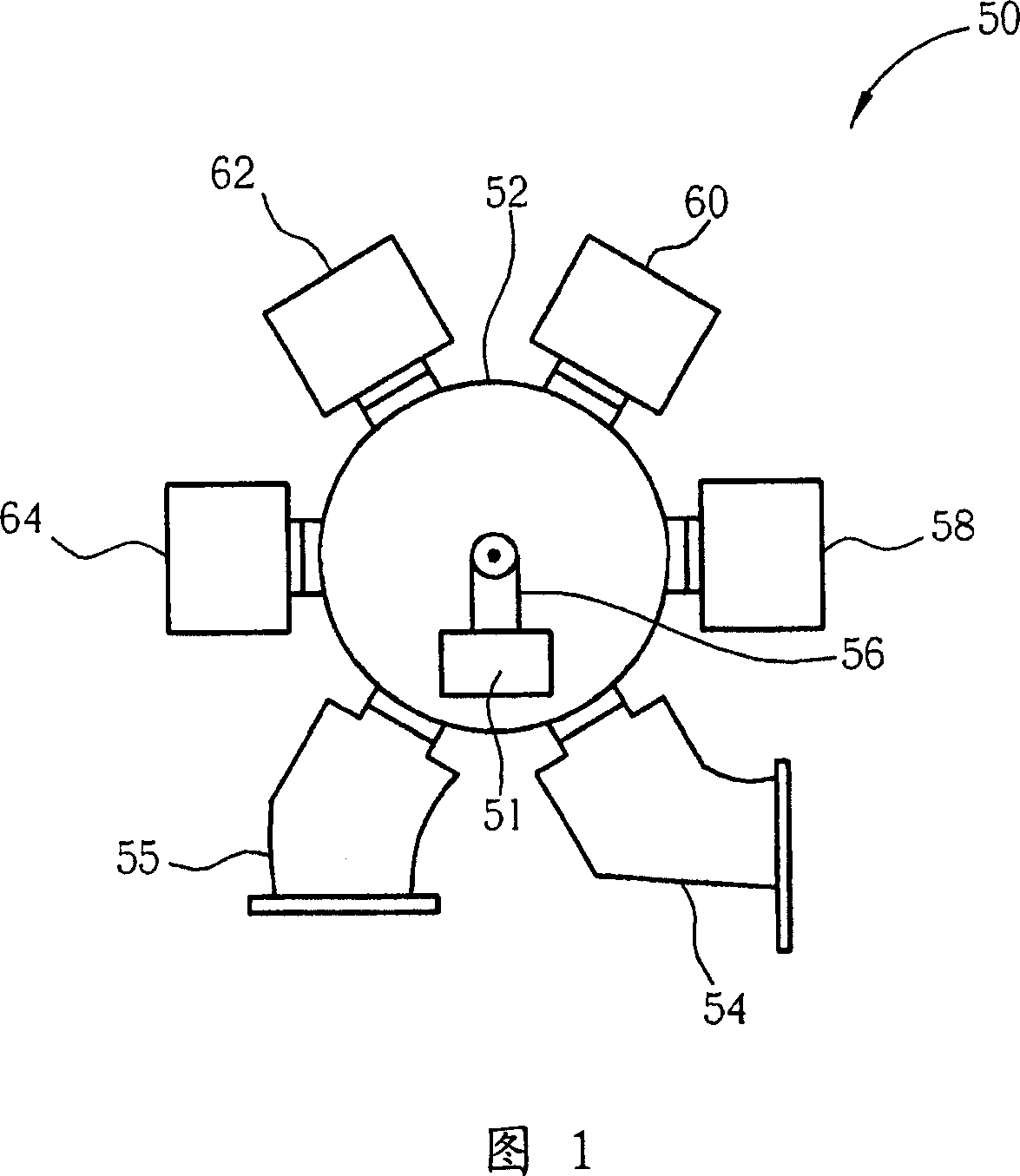

[0026] As mentioned earlier, before the physical vapor deposition manufacturing process, all glass substrates need to be loaded into the heating chamber for a preheating action. After the glass substrates are heated, the glass substrates are sent to each sputtering chamber for processing. The substrate film-forming work, and these actions all use ceramic hooks to lift the glass substrate and place it on the glass substrate bearing seat.

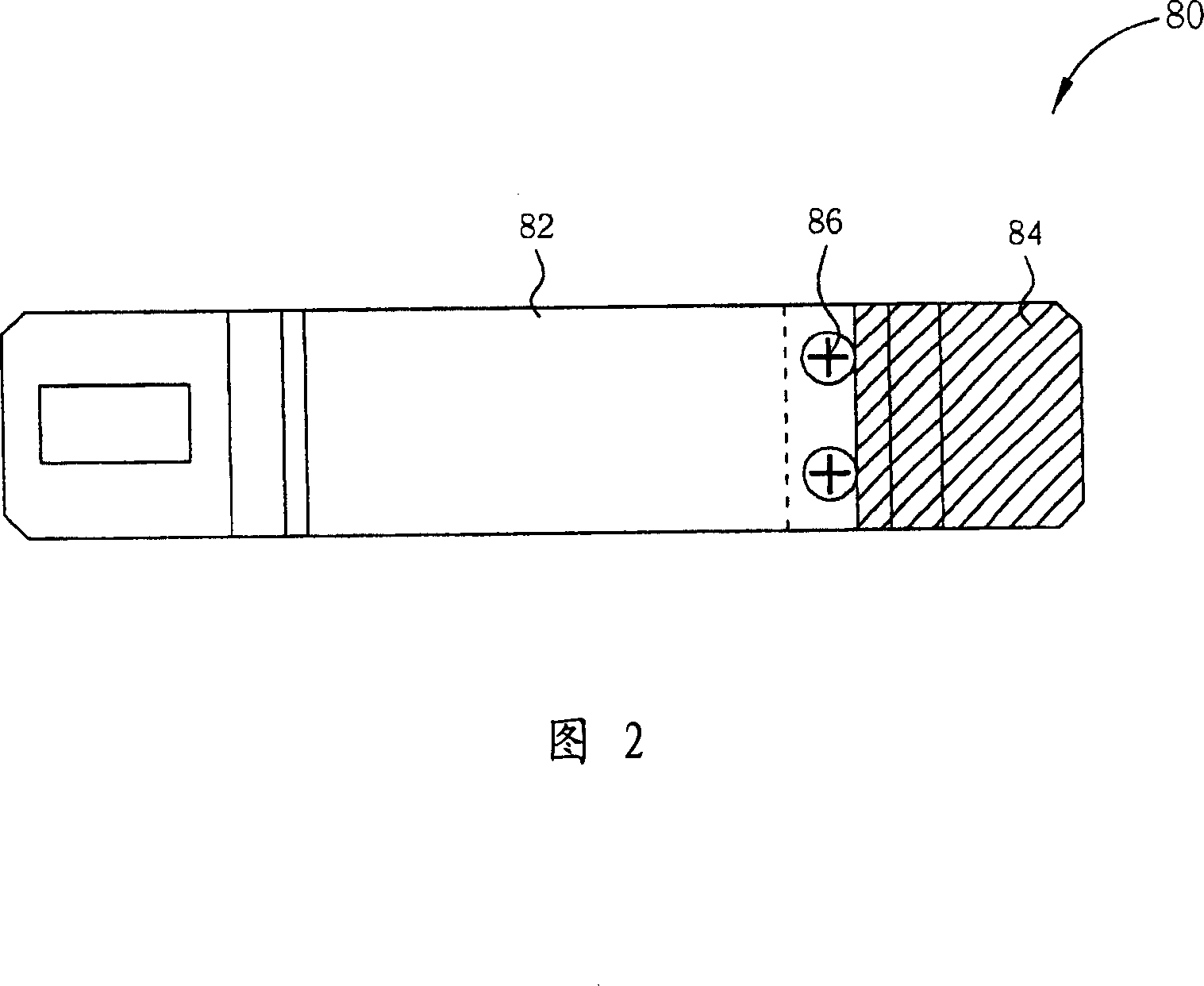

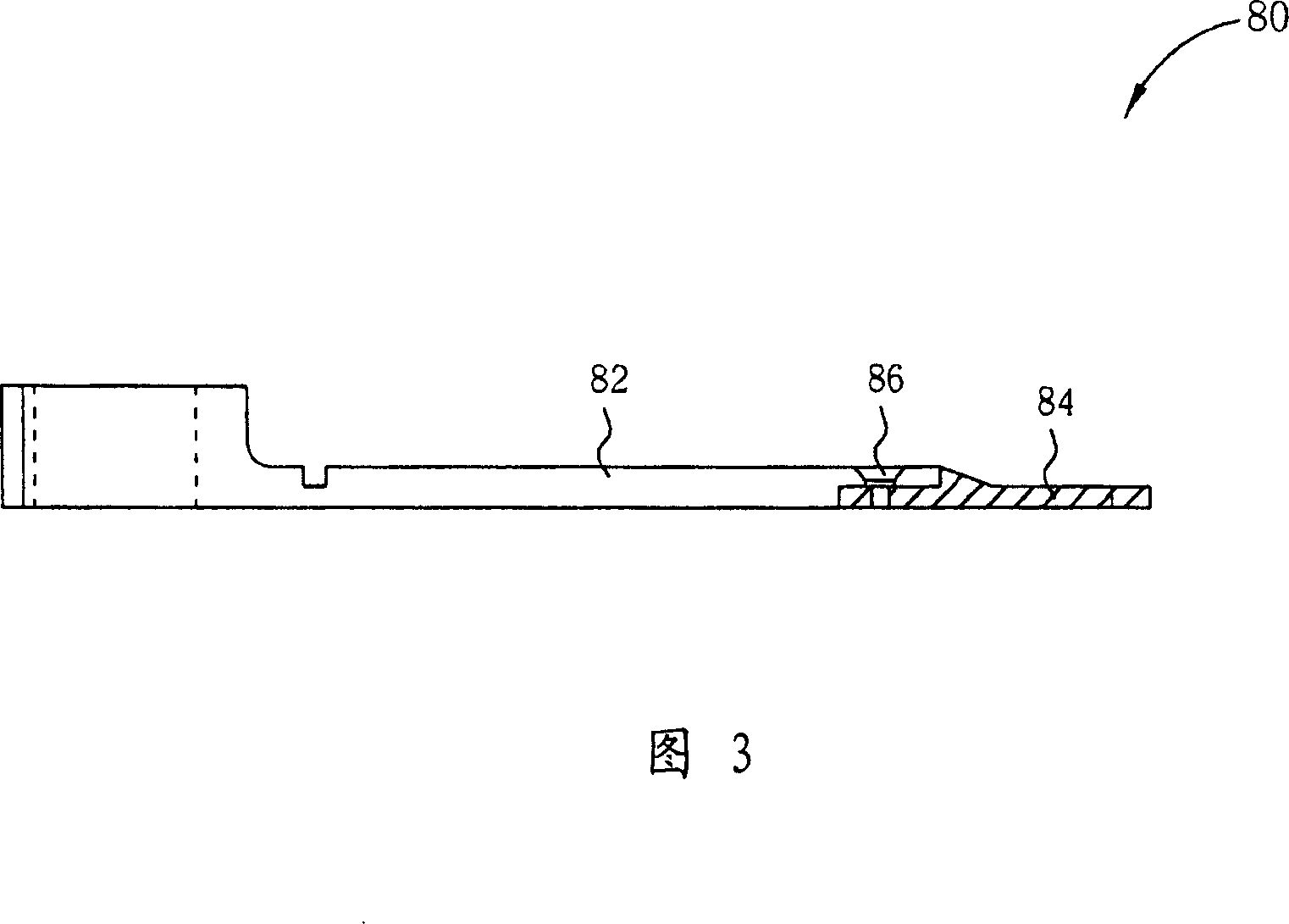

[0027] Please refer to FIGS. 2 and 3. FIG. 2 is a top view of the ceramic hook 80 of the present invention, and FIG. 3 is a side view of the ceramic hook 80 of the present invention. As shown in FIGS. 2 and 3, the ceramic hook 80 of the present invention includes a ceramic body 82 and a metal plate 84. The ceramic main body 82 includes a front end and a rear end, and the metal plate 84 is connected to the front end of the ceramic main body 82 in a detachable and fixed manner by using at least one Phillips flat head screw 86. In addition, the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com