Thinfilm solar cell component and its manufacturing method

A technology of solar cells and manufacturing methods, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as film layer peeling, battery reliability and stability decline, solar cell failure, etc., to increase bonding Strength and conductivity, and the effect of preventing peeling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

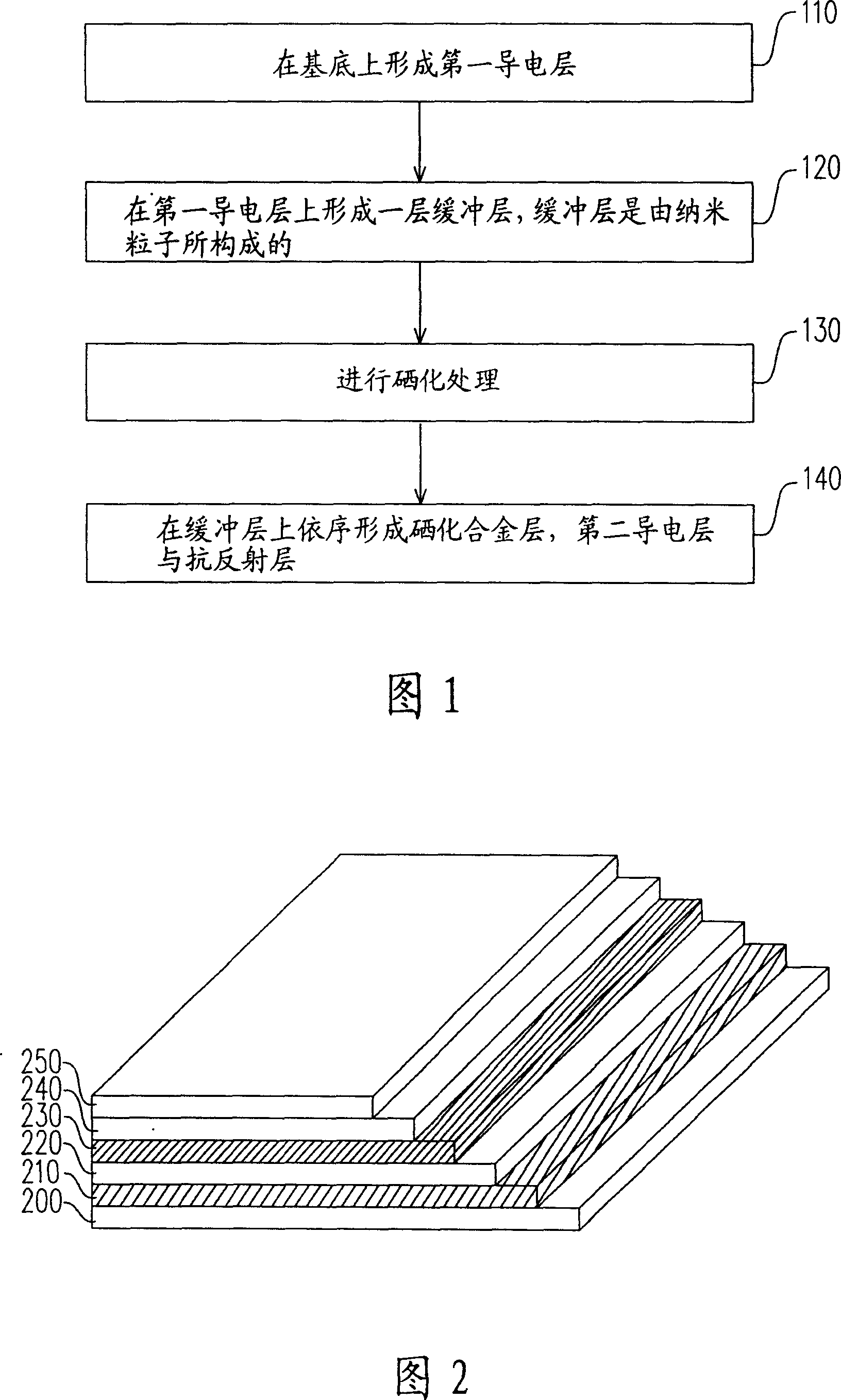

[0029] FIG. 1 is a flow chart showing a manufacturing process of a thin-film solar cell element according to an embodiment of the present invention.

[0030] Please refer to FIG. 1 , the manufacturing method of the thin film solar cell element is, for example, to firstly form a first conductive layer on the substrate (step 110 ). The material of the substrate is, for example, glass, metal foil, PET, and the like. The material of the first conductive layer is, for example, metal such as molybdenum or aluminum, and its forming method is, for example, physical vapor deposition. The thickness of the first conductive layer varies according to different current requirements, for example, it is between 0.2-1.0 μm.

[0031] Then, a buffer layer is formed on the first conductive layer, the buffer layer is composed of nanoparticles (step 120 ), and the particle size of the nanoparticles is, for example, less than or equal to 50 nm. The material of the buffer layer is, for example, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com