Steel net template for cast-in-situ light concrete wall body and construction technology

A lightweight concrete and wall technology, applied to walls, building components, buildings, etc., can solve the problems of increased raw material costs, uneven release agent, and reduced sound insulation effect, so as to avoid uneven painting and reduce environmental pollution , The effect of improving the sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

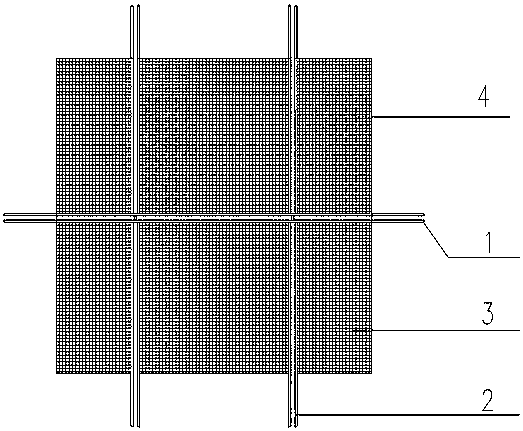

[0015] The steel mesh formwork structure of the cast-in-place lightweight concrete wall of the present invention is as follows figure 1 As shown: there are main back flute 1 and secondary back flute 2, steel wire mesh 3 is fixed on the inner side of main back flute 1 and secondary back flute 2, and needle punched cloth 4 is covered on the steel wire mesh 3. The mesh size and material of the steel wire mesh 3 should satisfy the needling cloth (acupunctured non-woven fabric) to breath and prevent slurry after working together and meet the strength requirement of pouring lightweight concrete.

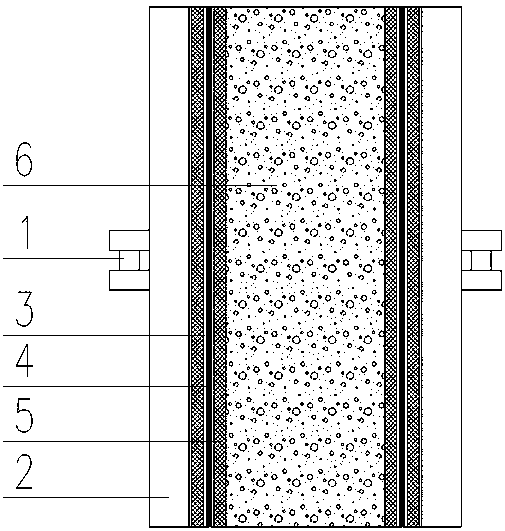

[0016] The construction technology of steel mesh formwork for cast-in-place lightweight concrete wall is as follows: figure 2 As shown, proceed as follows:

[0017] a. Install cast-in-place lightweight concrete walls with non-demolition keel metal mesh 5;

[0018] b. Cover (paste) the needle-punched cloth 4 on the non-removable keel metal mesh 5;

[0019] c. Fix the steel wire mesh 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com