Synthetic cork compound

A technology for mixtures, cork, used in liquid handling, closure with stoppers, transport and packaging, to solve problems such as breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

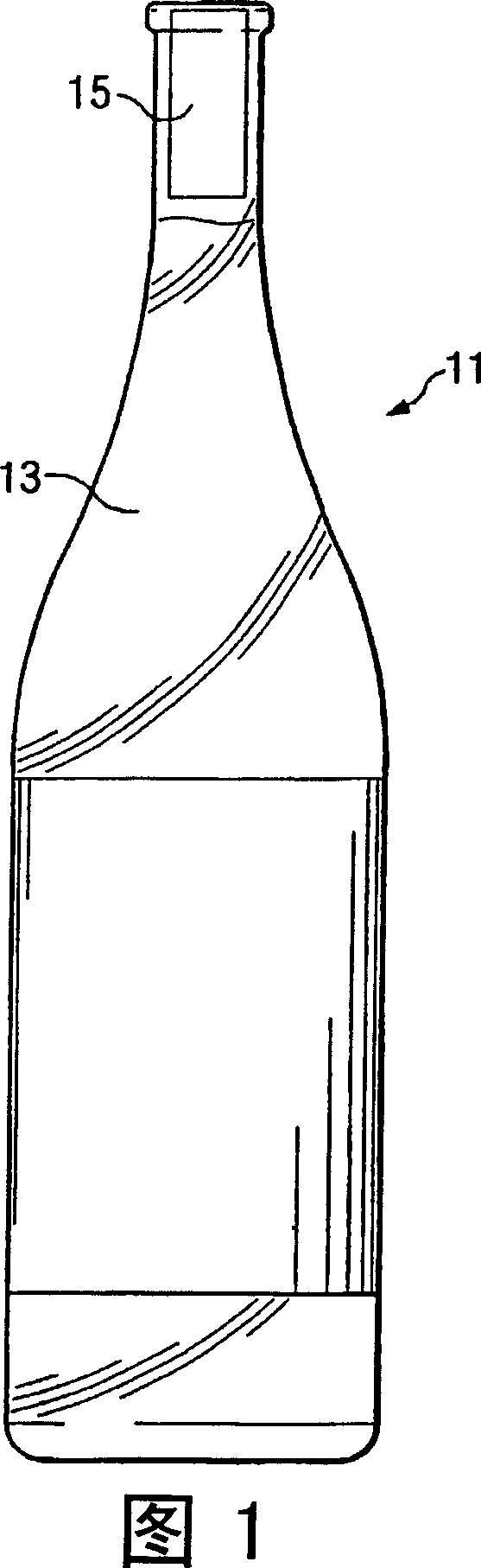

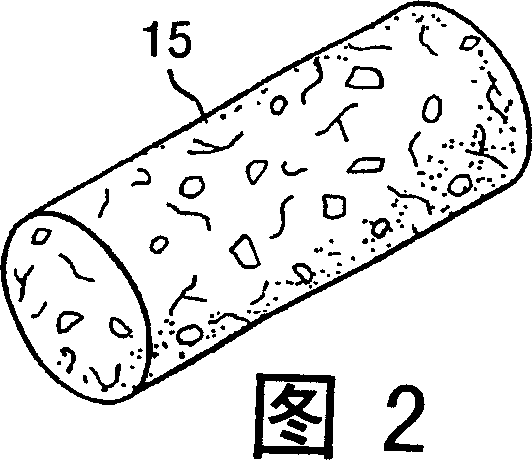

[0034] A synthetic cork mixture was formulated using about 40.7% by weight polydimethylvinylpolysiloxane polymer and about 27.1% by weight fumed silica filler. About 1.3% by weight of high vinyl polysiloxane polymer was added to provide sufficient active sites for the silicon hydride to react with the polymer during crosslinking. About 1.0% by weight toasted oak chips and about 0.25% by weight zinc ferrite pigment were then mixed with the silicone polymer and filler. While a variety of different pigments can be used, zinc ferrite pigments can help mimic the look of natural cork. After adding about 26.2% by weight of soda lime borosilicate and about 0.08% by weight of ethylcyclohexanol, about 2.3% by weight of silicon hydride was added and mixed. The last ingredient added was about 0.99% by weight chloroplatinic acid. Add this component and mix well with other ingredients. The order in which the various ingredients of the mixture are mixed is very important to ensure that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com