Microvalve integrated in flow passage

A micro valve and flow channel technology, applied in valve devices, safety valves, balance valves, etc., can solve the problems of difficulty in implementation, low reliability, and large additional volume, and achieve easy mass production, cost savings, and processing technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

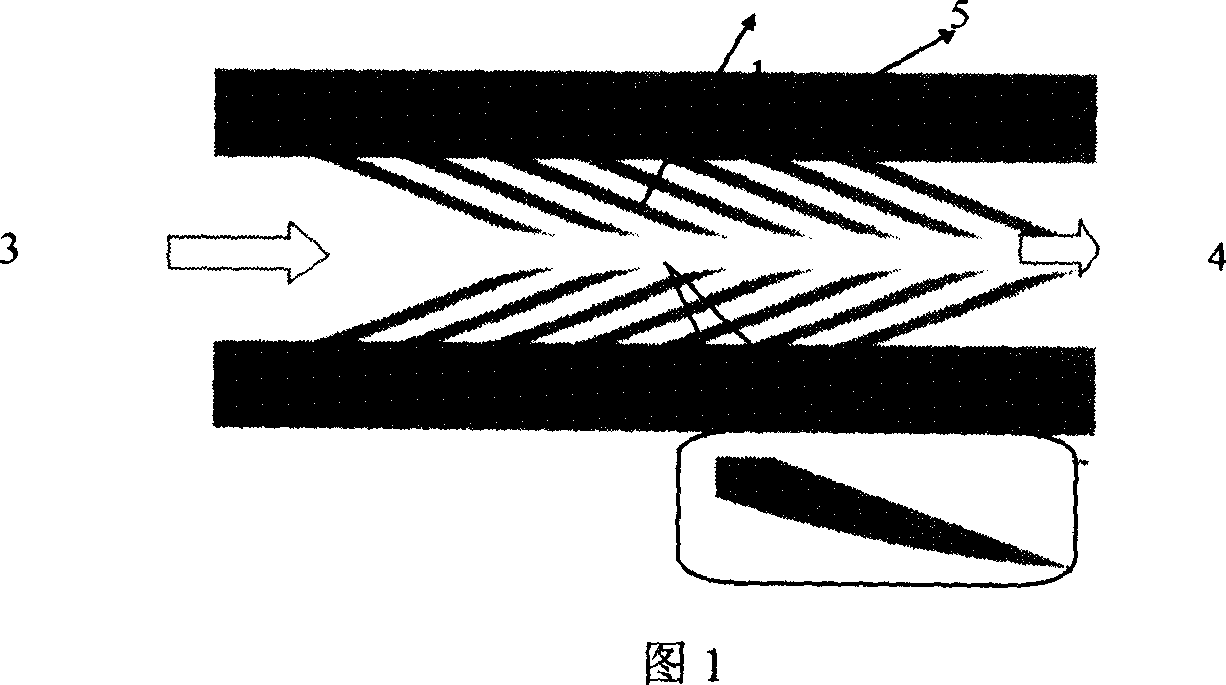

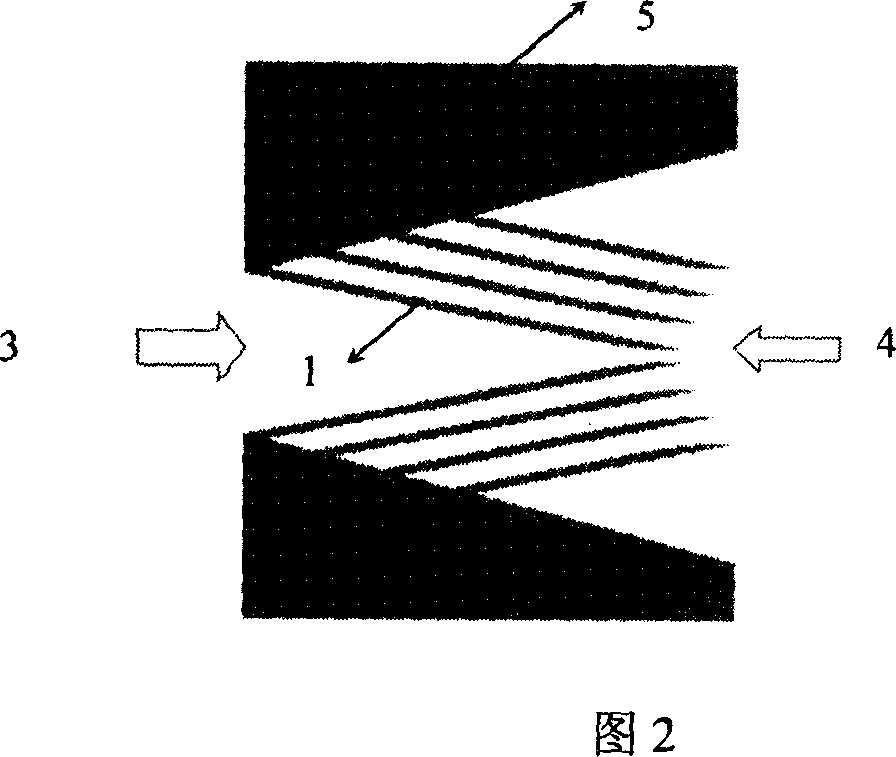

[0021] Embodiment 1: The valve body includes a micro-channel 5 and a parallel arrangement of micro-movable scale structures 1 connected to its side wall. The micro-channel can be a columnar structure, or a diffusion tube structure with a certain cone angle. As shown in Figure 2, the micro-scales 1 should be arranged along the direction of diffusion. Here, the micro-movable scales 1 play the role of valve plates. The opening and closing of the scales 1 cater to the inertial flow inside the fluid. When the fluid flows in the opposite direction, the resistance is small and the flow is smooth; on the contrary, when the fluid flows against the direction of the scales 1, the scales 1 are opened, and the distance of the flow channel is narrowed. At the same time, the reverse disturbance is increased, so that the reverse The flow rate decreases, and the flow rate in the forward direction is greater than the flow rate in the reverse direction, which can play the role of a one-way valve....

Embodiment 2

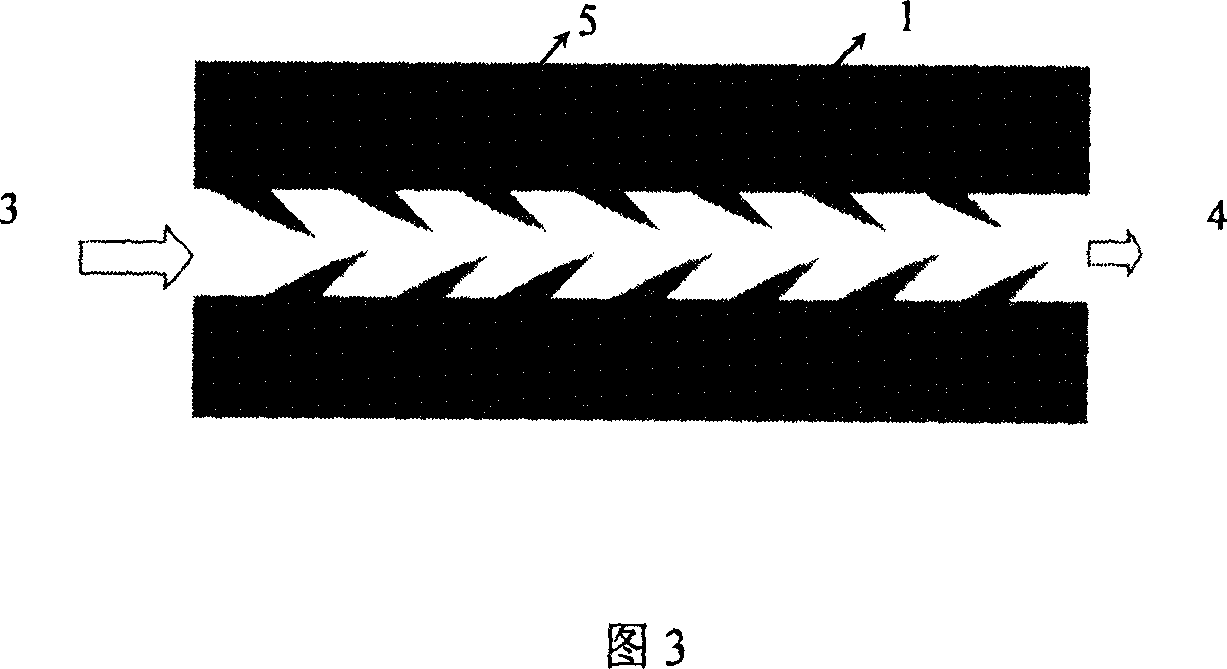

[0022] Embodiment 2: The valve body includes a micro-channel 5 and a micro-fixed scale structure 1 connected to its vertical side wall. The fixed scale can be a structure similar to a shark fin, or a fixed sheet structure, and the micro-scale structures are parallel to each other. Arrangement, wherein each group of micro scales on the side wall of the flow channel are interspersed with each other or arranged symmetrically. As shown in Figure 3; the micro-channel 5 can be columnar; the two side walls of the micro-channel 5 can also form a certain angle to form a diffusion pipe flow channel 5 (the flow in the diffusion direction is large, and the scales should be arranged along the direction of diffusion) The layout is shown in Figure 4. The main function of the fixed scales is to minimize the disturbance along the flow direction and increase the disturbance against the flow direction, thus changing the flow resistance characteristics of the micro-channel and increasing the effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com