Method of preparing ultra-fine hard alloy mixture of tungsten and cobalt and product

A technology of cemented carbide and mixed materials, which is applied in the field of preparation of ultrafine cemented carbide tungsten and cobalt mixed materials and products, can solve the problems of unmanufactured nano-hard alloys, non-uniform grain growth, lattice distortion, etc. Achieve the effects of simplifying processing equipment, avoiding growth, and uniform sintering shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

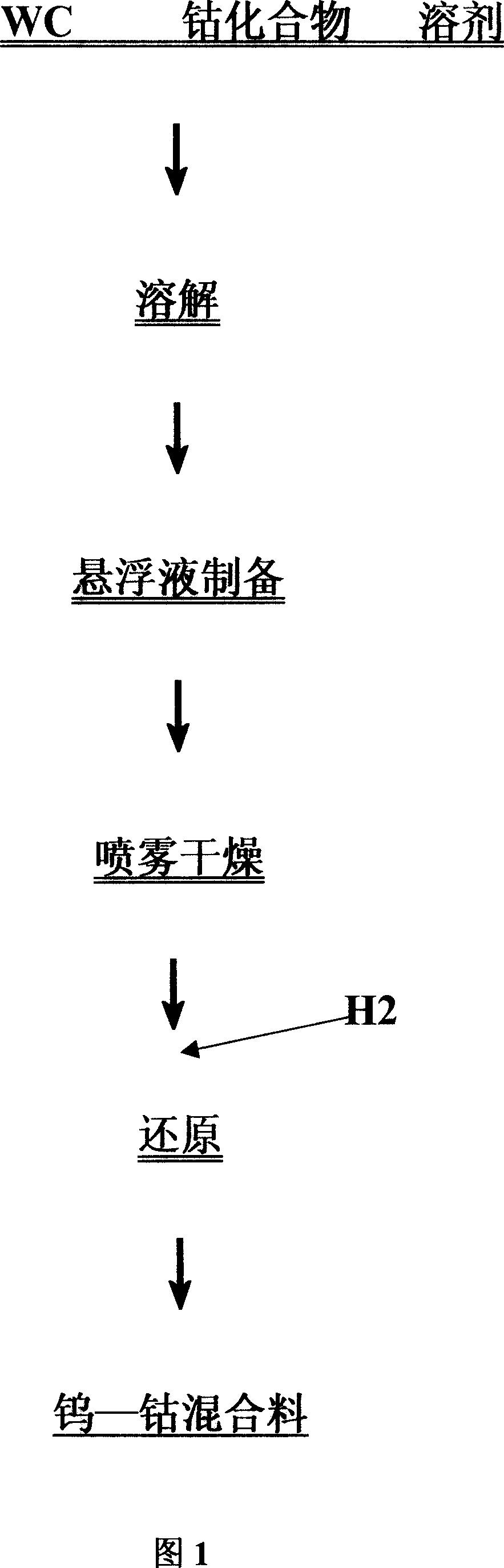

Method used

Image

Examples

Embodiment 1

[0019] This example method includes the following steps:

[0020] 1. Raw materials: 1.5 kg of 0.4 μm WC powder prepared by our company, 0.4 kg of cobalt acetate, and 500 ml of alcohol;

[0021] 2. Put the cobalt acetate into the alcohol and stir well until all the cobalt acetate is completely dissolved to form a completely clear and transparent cobalt acetate solution;

[0022] 3. Slowly add WC powder to the above cobalt acetate solution while stirring, and continue stirring for 0.2-1 hour after adding WC to ensure that the WC powder is evenly dispersed in the solution;

[0023] 4. Spray-dry the above-mentioned WC powder suspension. Spray-drying is carried out under the condition of continuously stirring WC and cobalt acetate compound solution mixed slurry. The drying temperature is between 100-120°C. The spraying rate depends on the particle size of WC It is determined that the smaller the particle size, the faster the spray rate can be. Generally, it should be ensured that ...

Embodiment 2

[0029] Example 2 Example 3 Example 4 Example 5

[0030] WC powder particle size 0.2μm 0.4μm 0.6μm 0.8μm

[0031] WC powder weight 1Kg 1.5Kg 2Kg 2Kg

[0032] Cobalt compound Cobalt acetate 450g Cobalt oxalate 300g Cobalt acetate 800g Cobalt oxalate 450g

[0033] Solvent Ether Methanol Ether Ethanol

[0034] Solid-liquid ratio 1:5 1:9 1:3 1-6

[0035] Drying temperature 100°C 100°C 110°C 120°C

[0036] Reduction temperature 400-500℃ 550-650℃ 600-700℃ 700-800℃

[0037] The above-mentioned solid-to-liquid ratio refers to the volume ratio of the ultrafine tungsten carbide powder to the organic cobalt compound solution.

[0038] The mixed powder that produces with above-mentioned embodiment also can make the cemented carbide grain size size of making and initial powder grain size adapt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com