Heating solidified low density liquid silicon rubber composition and low density silicon rubber formed object

A liquid silicone rubber, heating and curing technology, applied in the field of low specific gravity liquid silicone rubber composition, can solve the problems of low true density, insufficient hardness change and damage of the storage stability of the silicone rubber composition, and achieve small hardness change, Small compression set and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

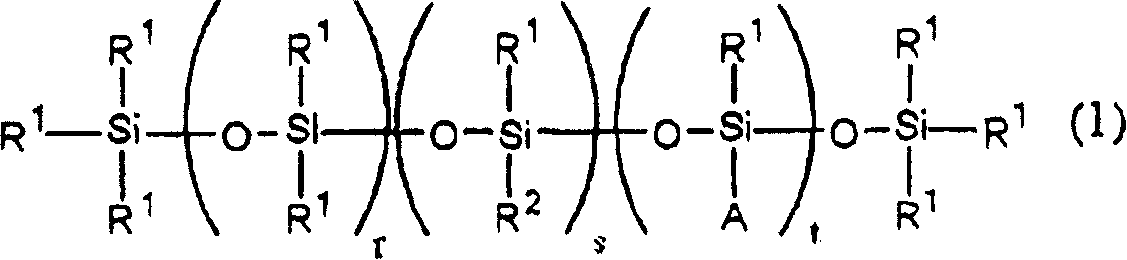

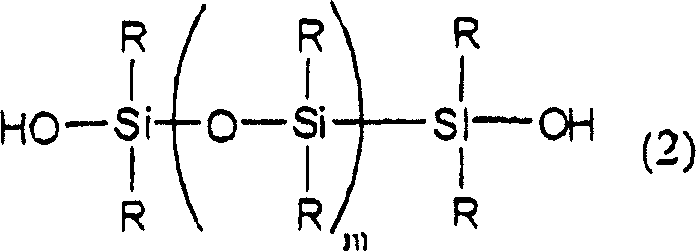

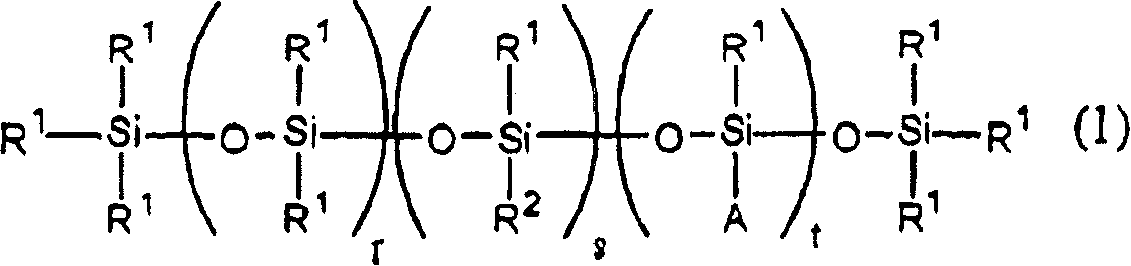

[0070] 92 parts of trimethylsiloxy terminated methylvinylpolysiloxane / dimethylpolysiloxane copolymer (vinyl content 0.12% by weight) at both ends of the molecular chain with a viscosity of 40,000mPa·s, the viscosity 2 parts of dimethyl hydroxysilyl-terminated dimethylsiloxane oligomer at both ends of the molecular chain of 40mPa·s, the following formula (3):

[0071]

[0072] 2 parts of the organosiloxane oligomer indicated, the specific surface area of the BET method treated with hexamethyldisilazane is 200m 2 3 parts / g of fumed silica, glass hollow micropowder (manufactured by Sumitomo Triem Co., Ltd.; trade name "Glass Bubbles S38", average particle diameter 40 μm, true specific gravity 0.38g / cm 3) 30 parts into a loss mixer and mixed evenly, heated and stirred at 170°C / 60 minutes under reduced pressure, and then cooled for 30 minutes to obtain a fluid liquid silicone rubber basic mixture. Next, to this liquid silicone rubber base mixture was added a two-terminal dime...

Embodiment 2

[0077] In Example 1, a liquid silicone rubber composition was produced in the same manner as in Example 1, except that 0.025 parts of cerium oxide fine powder was blended without heating and mixing when producing the liquid silicone rubber base mixture. Then, various characteristics were measured in the same manner as in Example 1. The results are shown in Table 1.

[0078] Example 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com