Nano porous zinc oxide thin film with high C-axis orientation and preparation method thereof

A zinc oxide thin film, nanoporous technology, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems such as precedents in the field of useless thin film synthesis, and achieve the effect of no high-temperature heat treatment equipment, large roughness, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Preparation of zinc-ammonia ion precursor. 0.1 mol / l zinc sulfate is dissolved in deionized water to form a solution, and concentrated ammonia water (25-28%) is slowly added dropwise thereto to obtain a stable zinc-ammonium complex ion precursor solution. The molar concentration ratio of zinc ions to ammonia water is 1:10.

[0026] 2. Use ordinary slide glass as the substrate. Firstly, soak it with hot dilute sulfuric acid (about 60°C), and then fully rinse it with acetone, ethanol and deionized water respectively; after treatment, put it in a vacuum dryer for later use.

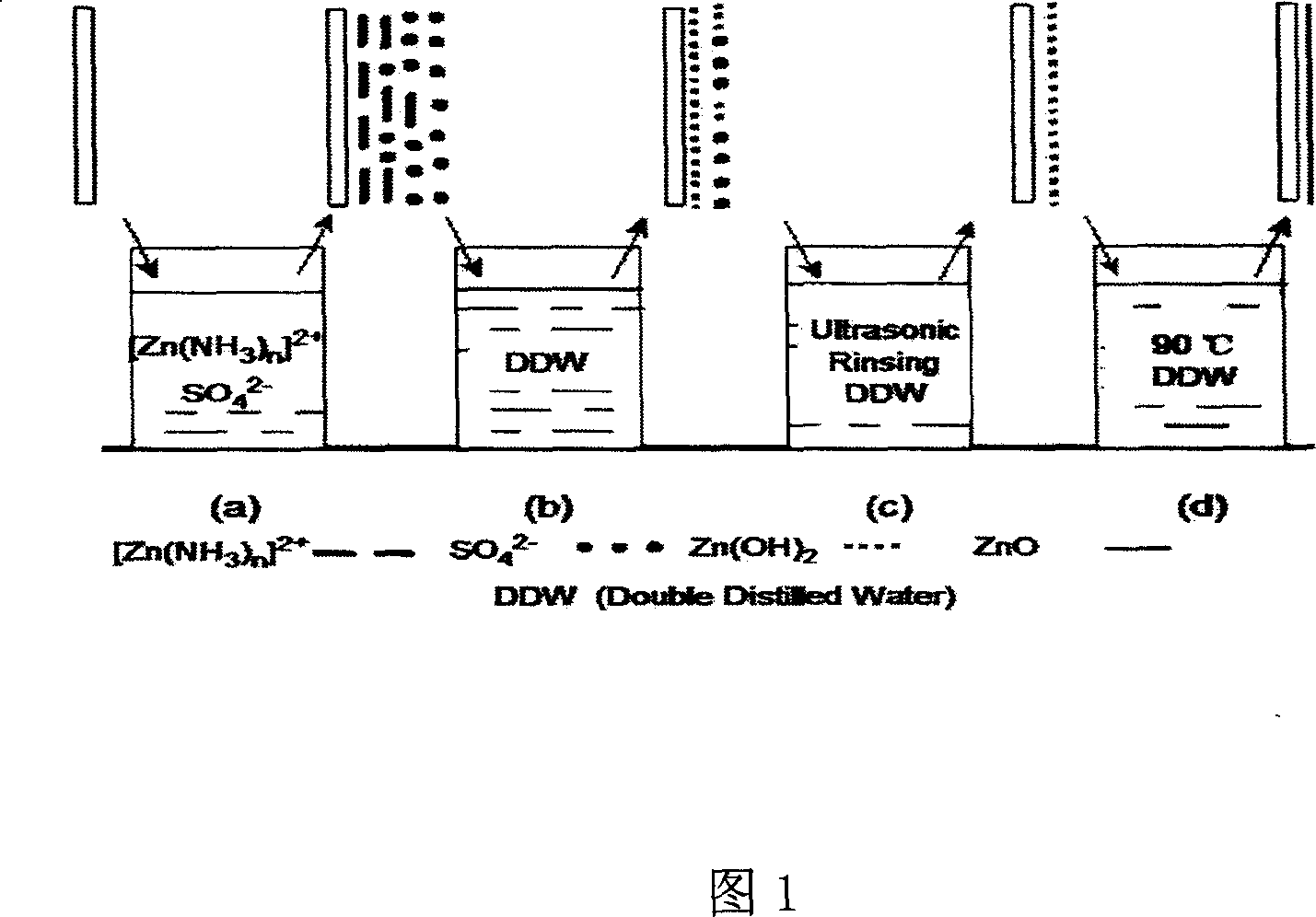

[0027] 3. Film growth. Divided into the following four steps:

[0028] a) Place the substrate in the precursor solution and perform [ZN(NH 3 )] 4 2+ Adsorption, duration 15 seconds;

[0029] b) The adsorbed [ZN(NH 3 )] 4 2+ The substrate was transferred to deionized water and allowed to stand for 20 seconds;

[0030] c) ultrasonically irradiating the substrate in another deionized aqueou...

Embodiment 2

[0035] 1. Preparation of zinc-ammonia ion precursor. 0.1 mol / l zinc acetate is dissolved in deionized water to form a solution, and concentrated ammonia water is slowly added dropwise thereto to obtain a stable zinc-ammonium ion precursor solution. The molar concentration ratio of zinc ions to ammonia water is 0.2.

[0036] 2. Use ITO conductive glass as the substrate. First rinse it with hot dilute hydrochloric acid (about 60°C) for a short time (about 10 seconds to 60 seconds), then fully rinse it with acetone, ethanol and deionized water respectively; after treatment, put it in a vacuum dryer for later use.

[0037] 3. Film growth. Divided into the following four steps:

[0038] a) Place the substrate in the precursor solution and perform [ZN(NH 3 )] 4 2+ Adsorption, duration 15 seconds;

[0039] b) The adsorbed [ZN(NH 3 )]4 2+ The substrate was transferred to deionized water and allowed to stand for 30 seconds;

[0040] c) ultrasonically irradiating the substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com