Semiconductor nano-wire, and semiconductor device provided with that nano-wire

A technology of nanowires and semiconductors, applied in semiconductor devices, semiconductor/solid-state device manufacturing, nanotechnology, etc., can solve the problems of small contact area between nanowires and source/drain electrodes, plastic substrates are not resistant to heat treatment to reduce contact resistance, etc. , achieve the effect of simplifying the manufacturing process, low contact resistance, and suppressing the deviation of mask alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

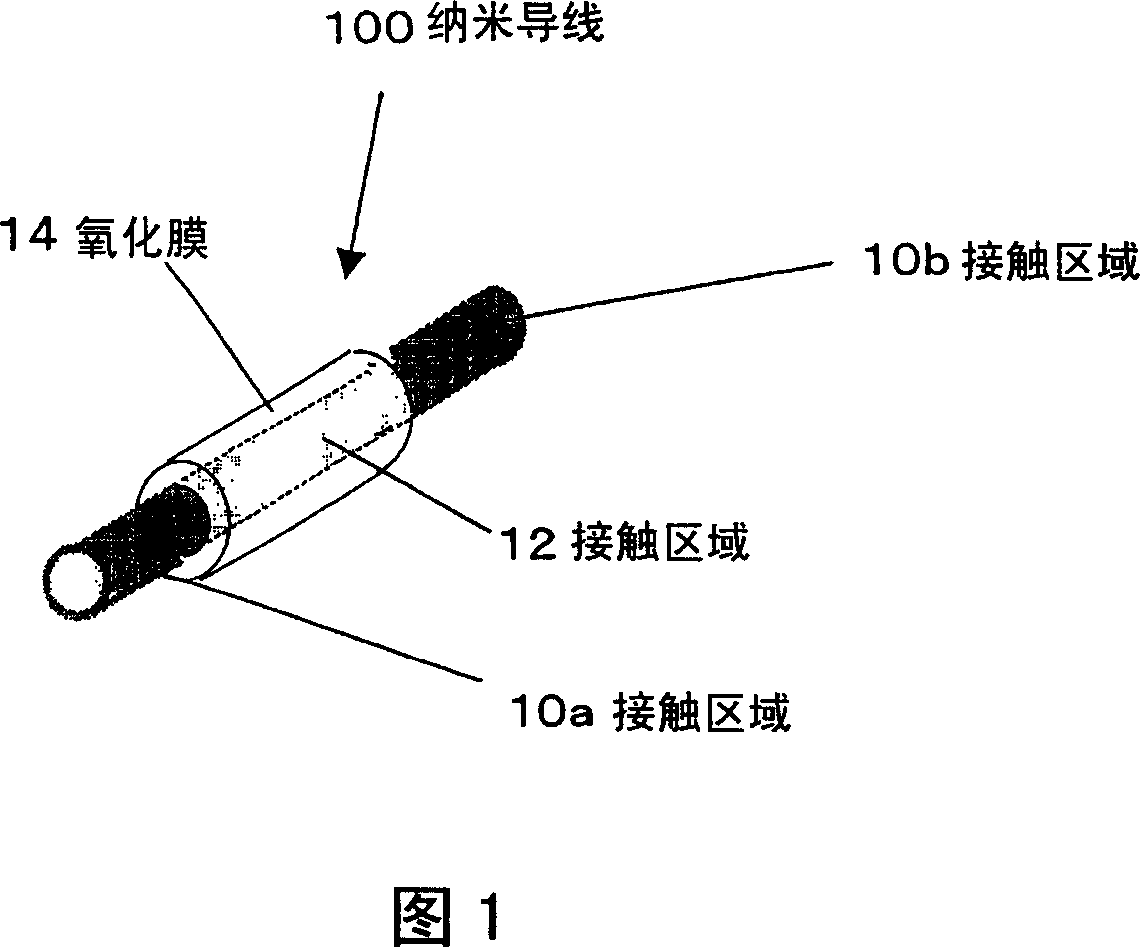

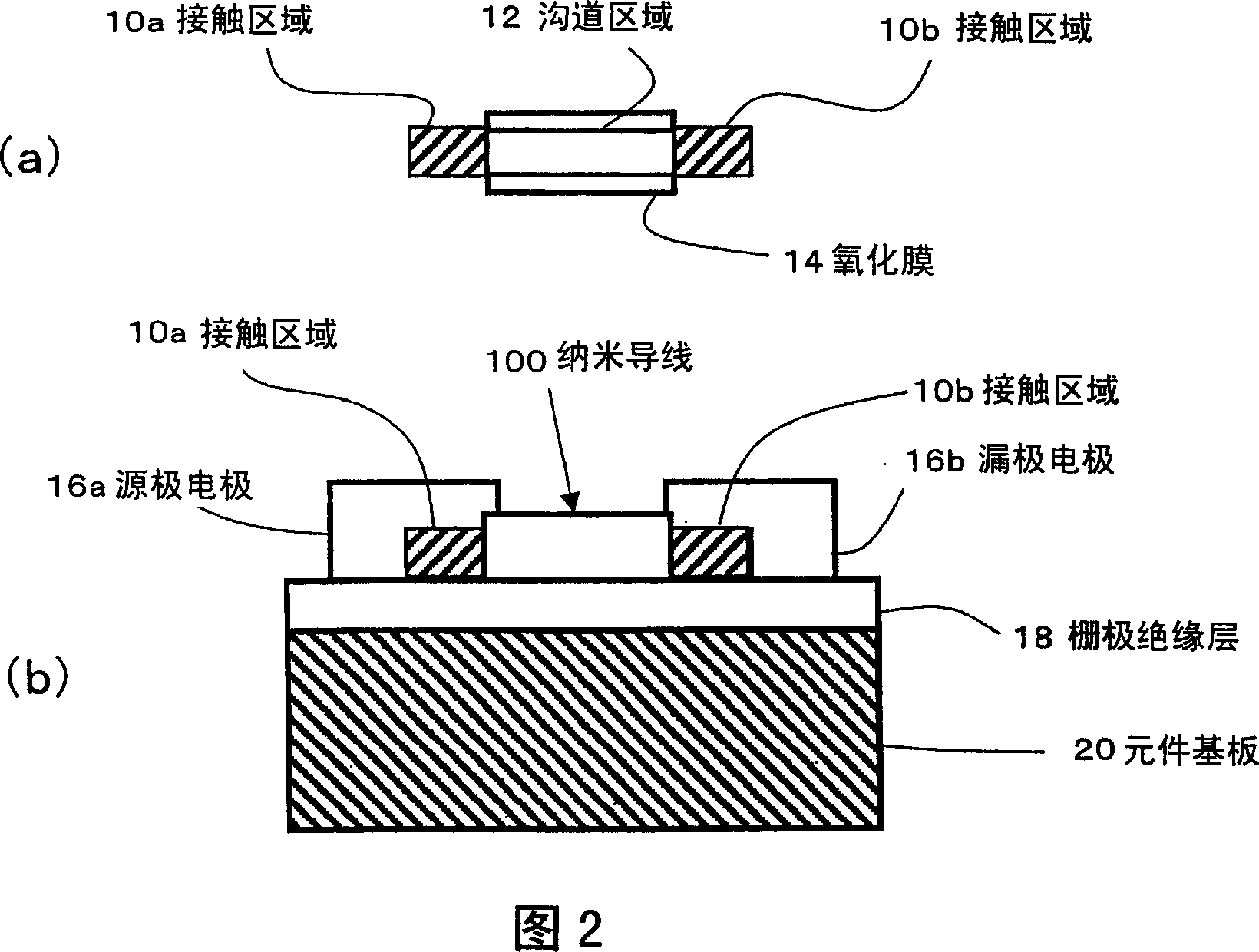

[0061] Hereinafter, a first embodiment of the nanowire of the present invention will be described with reference to FIGS. 1 and 2 . FIG. 1 is a perspective view of a nanowire 100 in this embodiment. 2( a ) is a cross-sectional view along the long axis direction of the nanowire 100 , and FIG. 2( b ) is a cross-sectional view of a field effect transistor including the nanowire 100 .

[0062] The nanowire 100 shown in FIGS. 1 and 2 has: a pair of contact regions 10a, 10b; and a channel region 12 connected to these contact regions 10a, 10b. In the present embodiment, the channel region 12 is formed of silicon (Si), but the contact regions 10a and 10b have conductive portions formed of a material different from Si at least on the surface. More specifically, the contact regions 10a, 10b are configured to include: a core portion made of Ge doped with a p-type impurity at a high concentration; and an alloy portion (here, The channel region of the p-type semiconductor is described, b...

Embodiment approach 2

[0107] Next, a second embodiment of the present invention will be described with reference to FIGS. 9( a ) and ( b ).

[0108] FIG. 9( a ) is a diagram showing a nanowire according to this embodiment, and FIG. 9( b ) is a plan view of a field effect transistor manufactured using such a nanowire.

[0109] The feature of this embodiment is that, as shown in Figure 9(a), a nanowire includes more than three contact regions 10 1 ~10 N (N is an integer greater than or equal to 3), two or more channel regions 12 1 ~12 M (M is an integer of 2 or more).

[0110] Such a nanowire can be produced by repeatedly performing the crystal growth process described with reference to FIGS. 5( b ) to ( d ), for example, by alternately growing Ge portions and Si portions. In this case, in that only the Si portion is covered with an insulating film and the surface of the Ge portion is selectively alloyed, it is different from the above-mentioned

[0111] The implementation is the same.

[0112]...

Embodiment approach 3

[0126] Next, a third embodiment of the present invention will be described with reference to FIG. 11 .

[0127] FIG. 11 is a plan view of a field effect transistor produced using the nanowire 200 of this embodiment. The difference from the field effect transistor shown in FIG. 6 is that the length of the channel region of the nanowire 200 is shorter than the distance between the source electrode 16a and the drain electrode 16b.

[0128] In this embodiment mode, the channel length is shortened beyond the limit of photolithography technology. As mentioned above, the channel length is defined as the length of the channel region of the nanowire, which can be controlled by the growth process of the nanowire. Therefore, the length of the channel region can be set to an extremely short value (for example, in the range of 50 to 1000 nm, preferably 500 nm or less), regardless of the limit of photolithography technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com