Preparation process of flue gas desulfurization and denitration material

A technology for desulfurization and denitrification, flue gas, applied in the field of preparation of flue gas desulfurization and denitrification materials, can solve the problems that cannot meet industrial applications, do not consider material production, material forming properties, shape, size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

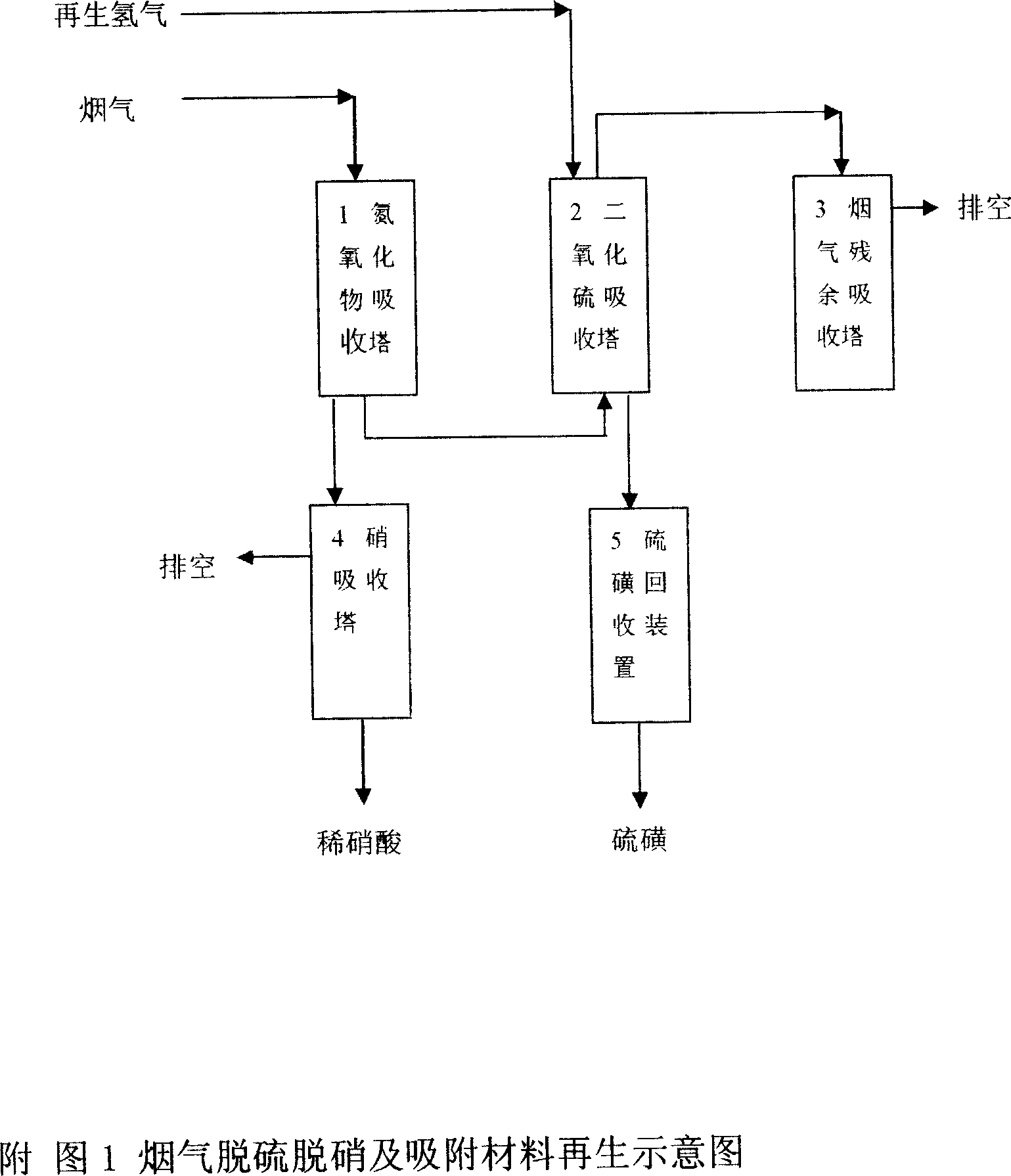

Image

Examples

Embodiment 1

[0027] 1977.2 grams of industrial magnesium nitrate, 476.5 grams of industrial aluminum nitrate, dissolved in deionized water to a specific gravity of 1.116; 526.5 grams of sodium hydroxide, 370.4 grams of sodium carbonate, dissolved in deionized water to a specific gravity of 1.147. Under stirring conditions, the two solutions were neutralized at a flow rate of 4L / min, the temperature of the reaction precipitation solution was 60°C, the pH was adjusted to 8.0, the precipitation time was 2.5 hours, and the aging time was 50min. The product was filtered, washed and dried , to obtain a white powder. Take 100g of powder, mix with 5g of kaolin, 10g of pseudoboehmite and 1g of turnip powder, add 3% nitric acid solution to make a spherical carrier with a diameter of 2mm. The shaped carrier was calcined at 400°C for 2 hours, the measured strength was 30N / m, and the specific surface was 100m 2 / g, the pore volume is 0.7cc / g. The adsorption capacity of nitrogen oxides in flue gas at ...

Embodiment 2

[0029] Replace magnesium nitrate with industrial copper nitrate, and other processes are with embodiment 1. Under stirring conditions, the two solutions were neutralized at a flow rate of 6 L / min in parallel, the temperature of the reaction precipitation solution was 80° C., the pH was adjusted to 10, the precipitation time was 1.5 hours, and the aging time was 60 minutes. Take 100g of powder, mix with 10g of kaolin, 3g of silica sol and 2g of turnip powder, and add 2% nitric acid solution. A spherical carrier with a diameter of 1 mm was made. The shaped carrier was calcined at 400°C for 5 hours, the measured strength was 40N / m, and the specific surface was 223m 2 / g, the pore volume is 1.3cc / g. The adsorption capacity of nitrogen oxides in flue gas at room temperature is 1250mg / g, and the adsorption capacity of sulfur dioxide in flue gas at 550°C is 1489mg / g.

Embodiment 3

[0031] Replace magnesium nitrate with industrial zinc nitrate, and other processes are with embodiment 1. Under stirring conditions, the two solutions were neutralized at a flow rate of 5 L / min in parallel, the temperature of the reaction precipitation solution was 70° C., the pH was adjusted to 8.8, the precipitation time was 2 hours, and the aging time was 70 minutes. Take 100g of powder, mix with 10g of kaolin, 2g of aluminum sol and 2g of methyl cellulose, add 3% nitric acid solution to make a spherical carrier with a diameter of 2mm, and calcinate the shaped carrier at 400°C for 3.5 hours. The measured strength is 60N / m, and the specific surface is 130m 2 / g, the pore volume is 1.6cc / g. The adsorption capacity of nitrogen oxides in flue gas at room temperature is 1352mg / g, and the adsorption capacity of sulfur dioxide in flue gas at 550°C is 1180mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com