Recovery method of separating waste composite material of aluminum and plastic

A composite material, separation and recycling technology, applied in the direction of plastic recycling, recycling technology, educts, etc., can solve the problems of inability to separate and degrade independently, and achieve the effect of reducing oxidation, eliminating oxidation, and solving separation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

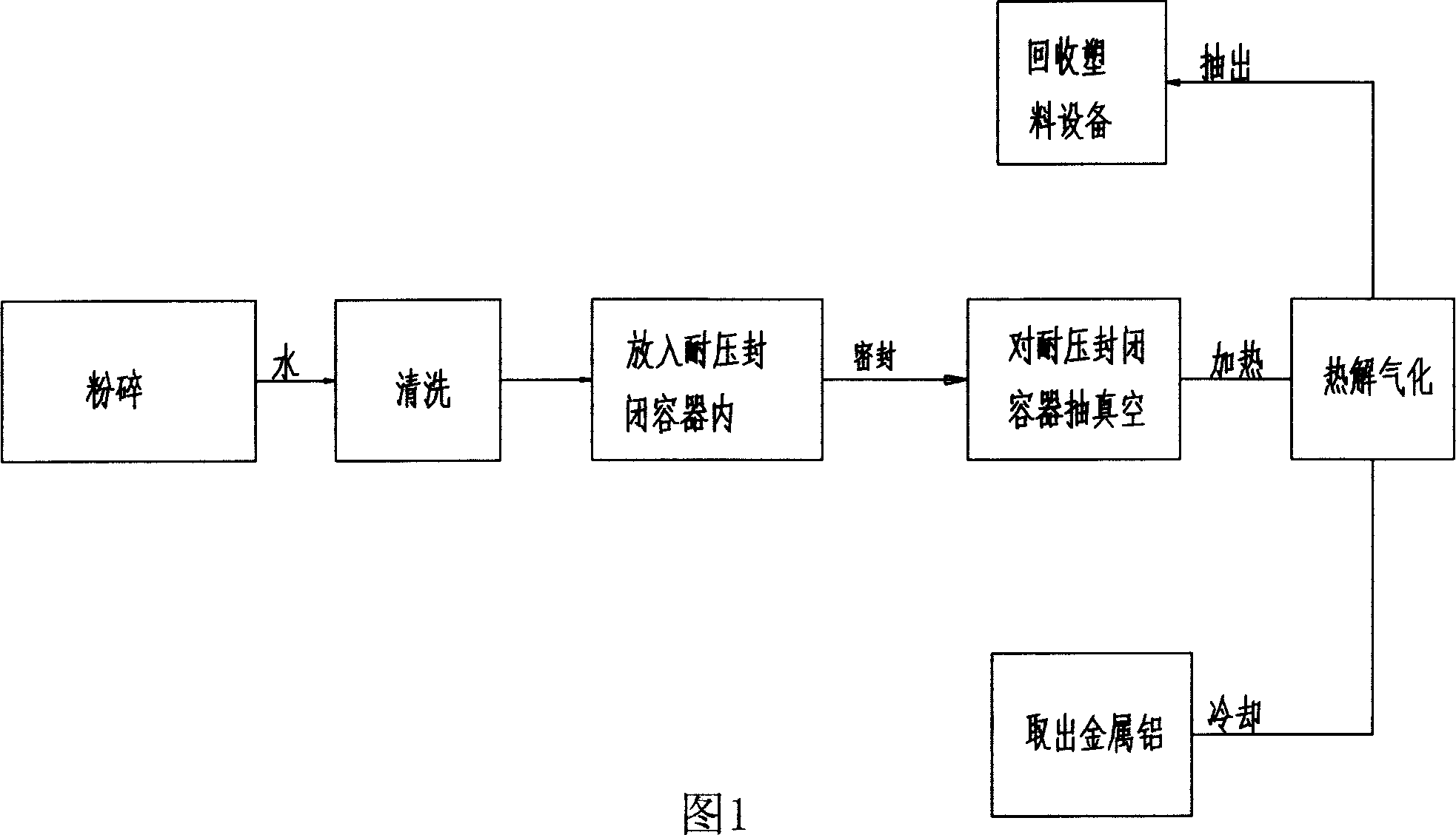

[0016] As shown in the figure, in an implementation method of the waste aluminum-plastic composite material separation and recovery method of the present invention, the collected waste aluminum-plastic composite material is first cleaned; the waste aluminum-plastic composite material is crushed by a shearing machine, and the It is crushed into strips or blocks. The width of the crushed aluminum-plastic composite material is not more than 50 mm. Put the crushed plastic-aluminum composite material into a pressure-resistant closed container and then seal it. Open and pressure-resistant seal The vacuum equipment connected with the container makes negative pressure in the pressure-resistant closed container, so as to reduce the oxidation of the non-ferrous metal aluminum by the air, and various methods can be used to heat the pressure-resistant closed container. The present invention uses electric heating in the container The equipment is powered on, and the plastic material in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com