Catalytic cracking catalyst and application

A catalytic cracking and catalyst technology, applied in physical/chemical process catalysts, molecular sieve catalysts, hydrocarbon cracking and hydrocarbon production, etc., can solve the problems of low propylene selectivity, low propylene yield, high hydrogen transfer activity of catalysts, etc., and achieve high yield , hydrogen transfer activity can be reduced, the effect of product distribution improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 1000 g of a commercially available HZSM-5 molecular sieve with a silicon-aluminum ratio of 35, and impregnate it with 4000 ml of a 0.15M ammonium phosphate solution. Rapidly stir and beat at 40°C for 2 hours, then filter the slurry, dry at 110°C for 2 hours, pulverize and then impregnate. After drying, roasting and crushing, the same method is used to modify it with Mg. Hereinafter referred to as the synthetic A-ZSM-5 modified molecular sieve, its phosphorus content is 6.0% (in P 2 o 5 In terms of), the magnesium content is 3.0% (in terms of MgO).

[0025] Take 1000g of a commercially available Y-type molecular sieve and impregnate it with 1200ml of 0.6M lanthanum nitrate solution. Rapidly stir and beat at 40°C for 2 hours, then filter the slurry, dry at 110°C for 2 hours, pulverize and then impregnate. After drying, roasting and crushing, it is ready for use. This composition is referred to as REY1 modified molecular sieve hereinafter, and its lanthanum conte...

Embodiment 2

[0028] A commercially available HZSM-5 molecular sieve with a silicon-aluminum ratio of 60 was modified with P and Mg elements respectively, and the modification method was the same as in Example 1. Hereinafter referred to as B-ZSM-5 modified molecular sieve, the compound contains 6.0% phosphorus (in P 2 o 5 Calculated), the magnesium content is 3.0% (calculated as MgO).

[0029] Adopt B-ZSM-5 and REY1 type modified molecular sieve (dry base, B-ZSM-5: REY1=9: 1), carrier is amorphous aluminum silicate, according to the method for preparing catalyst described in embodiment 1, Catalyst B was prepared. Based on the catalyst (dry basis), it contains 35% by weight of molecular sieves, 1.89% by weight of P 2 o 5 , 0.95% by weight of MgO, 0.28% by weight of lanthanum oxide.

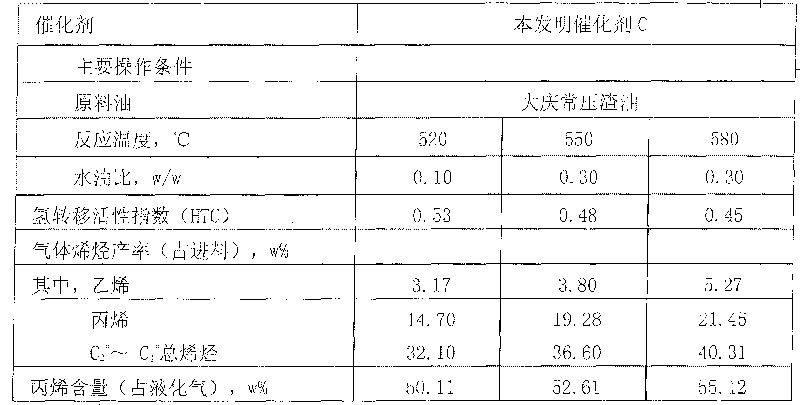

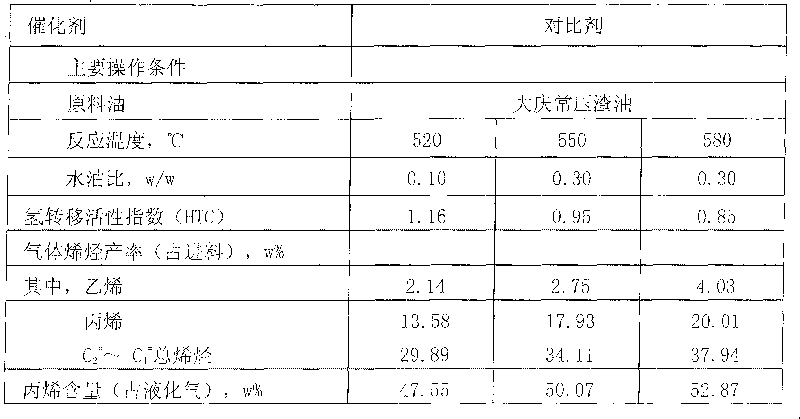

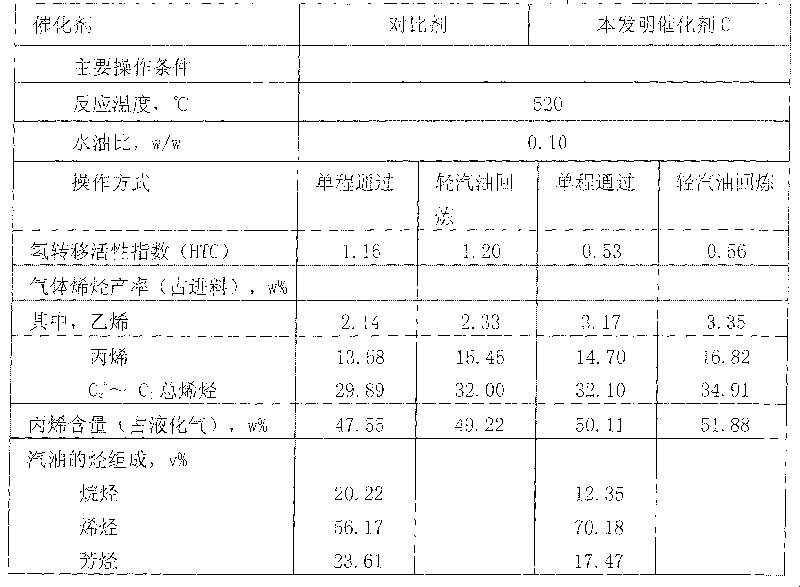

Embodiment 3

[0031] A commercially available HZSM-5 molecular sieve with a silicon-aluminum ratio of 120 was modified with P and Mg elements respectively, and the modification method was the same as in Example 1. This composition is referred to as C-ZSM-5 modified molecular sieve hereinafter, and its phosphorus content is 6.0% (in P 2 o 5 In terms of), the magnesium content is 3.0% (in terms of MgO).

[0032] Adopt C-ZSM-5 and REY1 type modified molecular sieve (dry basis, C-ZSM-5: REY1=9: 1), carrier is amorphous aluminum silicate, according to the catalyst preparation method described in embodiment 1, prepare Catalyst C was obtained. Based on the catalyst (dry basis), it contains 35% by weight of molecular sieves, 1.89% by weight of P 2 o 5 , 0.95% by weight of MgO, 0.28% by weight of lanthanum oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com