A kind of preparation method of catalyst for catalytic cracking to increase production of propylene

A catalytic cracking and catalyst technology, which is applied in catalytic cracking, physical/chemical process catalysts, hydrocarbon cracking and hydrocarbon production, etc., can solve the problems of increasing oil slurry yield, reducing gasoline yield, and low specific surface area, so as to reduce hydrogen transfer Activity and the effect of increasing the yield of propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

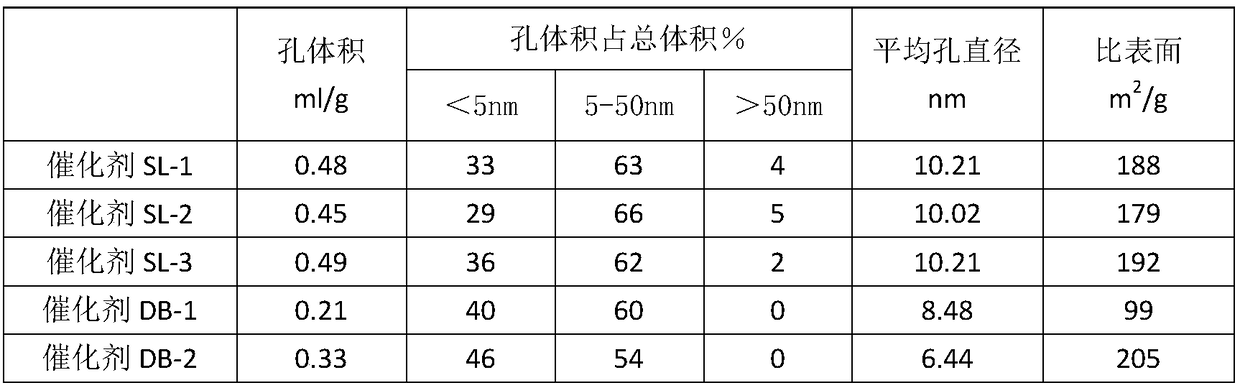

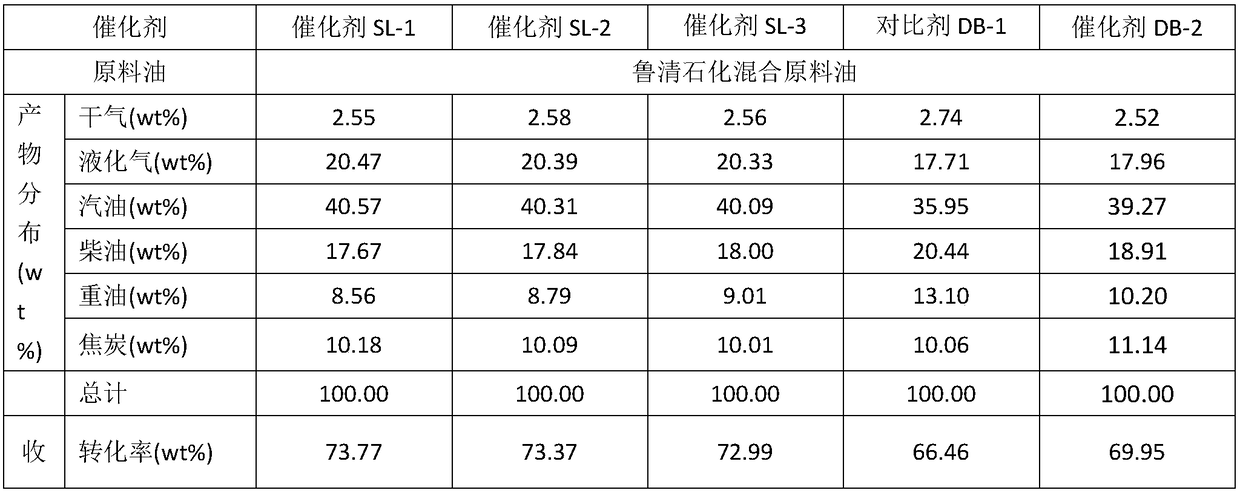

Embodiment 1

[0047] (1) 11.41 kg of ZSM-5 molecular sieve (silicon-aluminum ratio 25, dry basis content 92%) was mixed with 37.72 kg of deionized water, 11.53 kg of kaolin, and 11.03 kg of pseudo-boehmite, and stirred for 3 hours.

[0048] (2) Add 1.18 kg of 35 wt% hydrochloric acid to the slurry in (1), and stir for 45 minutes.

[0049] (3) Add 4.44 kg of water glass to the acidified solution and stir for 30 minutes until uniform.

[0050] (4) Add 0.51 kg of phosphoric acid to the slurry in (3), and stir for 25 minutes until uniform.

[0051] (5) Add 7.2 kg of alkaline silica sol to the above acidified slurry, stir for about 30 minutes until uniform, and obtain a catalyst slurry.

[0052] (6) The obtained catalyst slurry is spray-dried, washed with water and dried to obtain the catalyst SL-1.

Embodiment 2

[0054] (1) 13.33 kg of ZSM-5 molecular sieve (silicon-aluminum ratio 38, dry basis content 95%) was mixed with 33.53 kg of deionized water, 9.62 kg of kaolin, and 13.24 kg of pseudo-boehmite for 4 hours.

[0055] (2) Add 1.67 kg of 35 wt% hydrochloric acid to the slurry in (1), and stir for 50 minutes.

[0056] (3) Add 6.67 kg of water glass to the acidified solution and stir for 30 minutes until uniform.

[0057] (4) Add 0.61 kg of phosphoric acid to the slurry in (3), and stir for 20-30 minutes until uniform.

[0058] (5) Add 10.8 kg of alkaline silica sol to the above acidified slurry, stir for about 30 minutes until uniform, and obtain catalyst slurry.

[0059] (6) The obtained catalyst slurry is spray-dried, washed with water and dried to obtain the catalyst SL-2.

Embodiment 3

[0061] (1) 13.33 kg of ZSM-5 molecular sieve (silicon-aluminum ratio of 60, dry basis content of 90 wt%) was mixed with 41.70 kg of deionized water, 12.31 kg of kaolin, and 11.15 kg of pseudo-boehmite for 5 hours.

[0062](2) Add 0.93 kg of 35 wt% hydrochloric acid to the slurry in (1), and stir for 60 minutes.

[0063] (3) Add 2.22 kg of water glass to the acidified solution and stir for 30 minutes until uniform.

[0064] (4) Add 0.80 kg of phosphoric acid to the slurry in (3), and stir for 30 minutes until uniform.

[0065] (5) Add 3.6 kg of alkaline silica sol to the above acidified slurry and stir for about 30 minutes until uniform to obtain a catalyst slurry.

[0066] (6) The obtained catalyst slurry is spray-dried, washed with water and dried to obtain the catalyst SL-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com