System for vacuum pumping by steam produed by reduction dregs afterheat

A technology of vacuuming and slag waste heat, applied in the field of waste heat system, to achieve the effect of less heat loss, good environmental protection effect and elimination of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

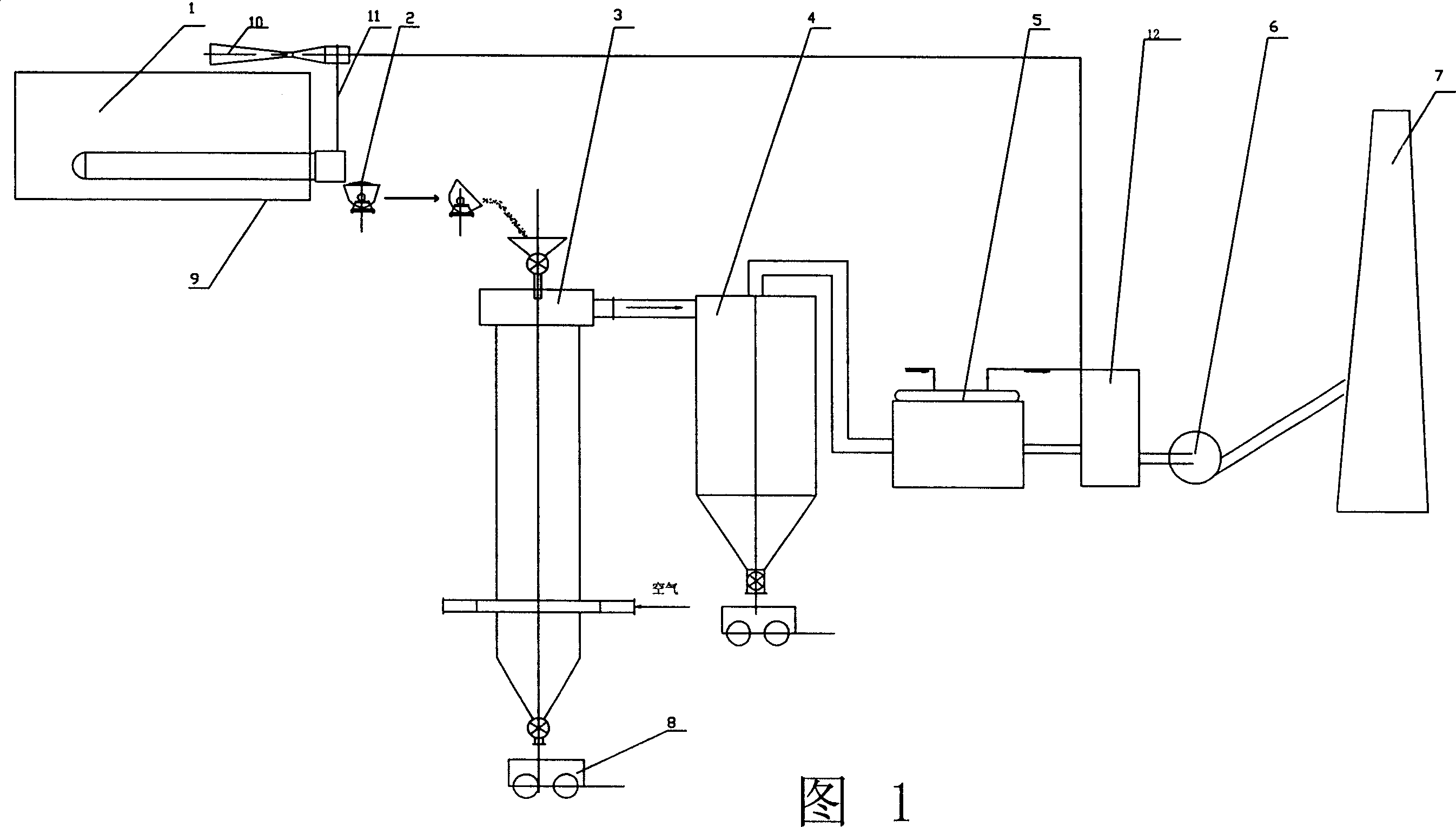

[0019] A vacuum pumping system that uses the waste heat of reducing slag to generate steam, as shown in Figure 1: it is composed of a reduction furnace 1, a fluidized bed 3, a dust collector 4, a waste heat boiler 5, an induced draft fan 6, and a chimney 7 connected in sequence through pipelines. In this way, a jet pump 10 connected to the gas outlet of the waste heat boiler 5 is provided on the upper part of the reduction furnace 1, a feeding bin is provided on the upper part of the fluidized bed 3, and a charging bin is provided on the lower part of the reduction furnace 1 to generate The reduced slag 2 is transported to the slag mine car 9 in the feeding bin of the fluidized bed 3. A bag dust collector 12 is provided between the waste heat boiler 5 and the induced draft fan 6, and a bag dust collector 12 is provided between the slag mine car 9 and the jet pump 10. Connected with a vacuum pipe 11, the dust collector 4 is a cyclone dust collector, and a cart 8 for dust removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com