Composite nanometer hydroxy apatitel medical polymer material tissue engineering stent material and preparation method

A nano-hydroxyapatite, tissue engineering scaffold technology, applied in medical science, prosthesis and other directions, can solve problems such as unfavorable tissue growth needs, drug burst release, etc., and achieve the effect of maintaining the release effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

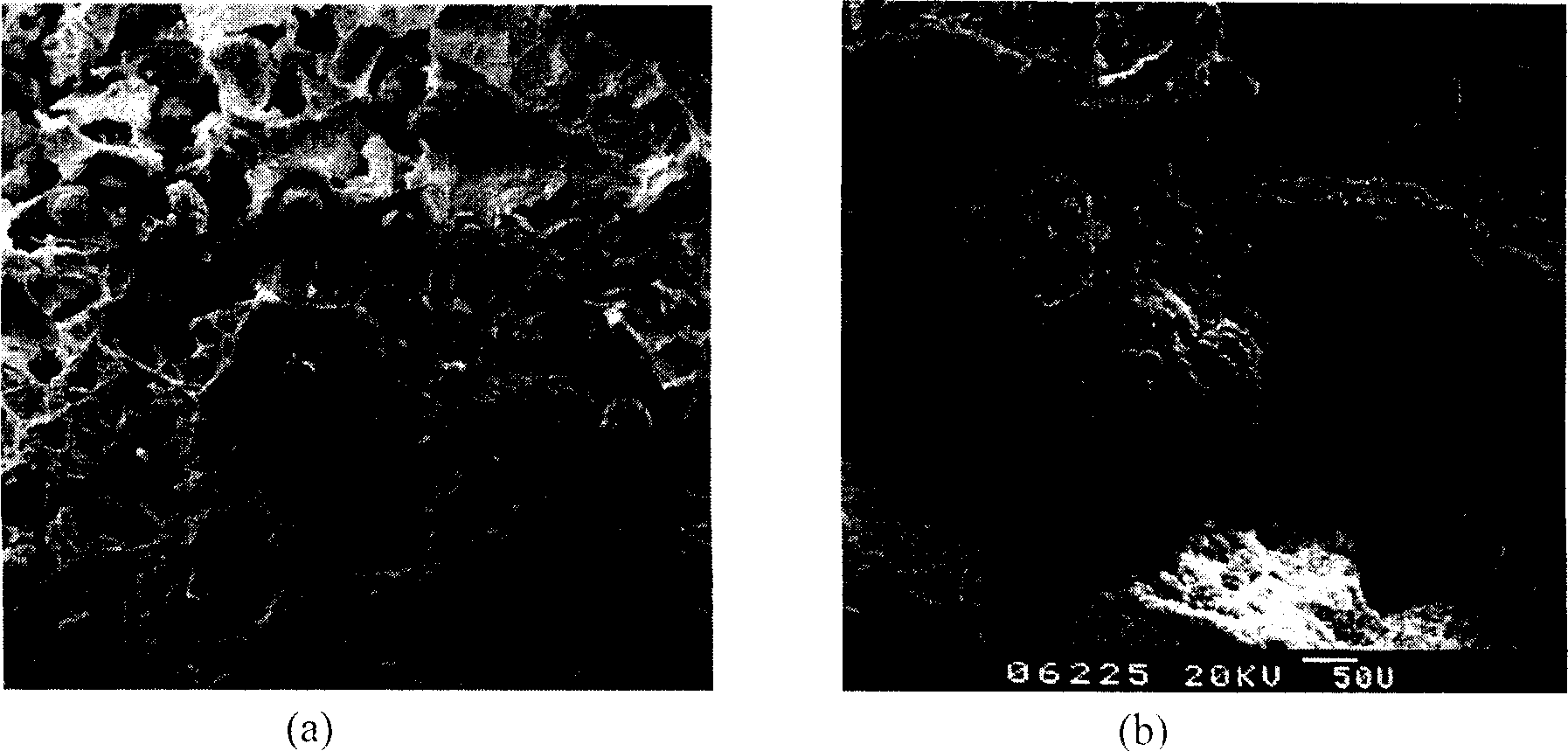

Image

Examples

Embodiment 1

[0030] Preparation of nano-hydroxyapatite / chitosan tissue engineering scaffold loaded with sodium alginate / chitosan microspheres

[0031] 1′: Preparation of sodium alginate / chitosan microspheres

[0032] The chitosan raw material is added into an aqueous solution containing 1% (w / v) acetic acid, stirred to dissolve, and prepared into a 3% (w / v) aqueous solution of chitosan acetic acid for future use. In addition, the sodium alginate raw material was dissolved in deionized water heated and kept at 70° C. and stirred to dissolve, and a 2% (w / v) sodium alginate solution was prepared for use.

[0033] Pour 150ml of liquid paraffin, 50ml of turpentine and 4ml of Tween 80 into a beaker, stir evenly, and obtain a mixed phase liquid containing 2% (v / v) Tween 80 oil. Although the amount of oil phase materials such as liquid paraffin and turpentine used does not need to be too limited, it is not conducive to the microspheres being sufficiently dispersed in the oil phase without agglome...

Embodiment 2

[0041] Preparation of nano-hydroxyapatite / chitosan tissue engineering scaffold loaded with chitosan microspheres

[0042] 1′: Preparation of chitosan microspheres

[0043] The chitosan raw material is added into an aqueous solution containing 2% (w / v) acetic acid, stirred to dissolve, and prepared into a 3% (w / v) aqueous solution of chitosan acetic acid for future use.

[0044] Pour liquid paraffin 100ml and turpentine 60ml and 2.5ml Tween 80 and 2.5ml span (span) in the beaker, stir, obtain containing 3.12% (v / v) Tween 80 / span oil mixed phase liquid.

[0045] Get 2ml of 50% glutaraldehyde solution, mix with distilled water to prepare 10ml of solution containing glutaraldehyde 10%. Then mix it with 10ml of liquid paraffin for later use.

[0046] Take 60ml of spare 3% chitosan solution, and add it dropwise to the above mixed oil phase liquid at a speed of 1-2 drops / min under the stirring condition of 3300-3500 rev / min. After half an hour, use The separatory funnel drips the ...

Embodiment 3

[0052] Preparation of nano-hydroxyapatite / chitosan tissue engineering scaffold loaded with sodium alginate microspheres

[0053] 1′: Preparation of sodium alginate microspheres

[0054] The sodium alginate is prepared into a 2% solution for later use.

[0055] Pour 100ml of liquid paraffin and 2.5ml Tween 80 into the beaker, stir well to obtain a mixed oil phase liquid containing 2.5% (v / v) Tween 80.

[0056] Take CaCl 2 10g and ZnCl 2 5g was added into 10ml of distilled water to prepare a solution for later use.

[0057] Take 60ml of spare 2% sodium alginate solution, and add it dropwise to the above-mentioned mixed oil phase liquid at a speed of 1-2 drops / min under the stirring condition of rotating speed of 3000-3400 rpm. After half an hour, use The separatory funnel drips CaCl into the sodium alginate solution emulsion at a rate of 1-2 drops / second 2 and ZnCl 2 mixed oil phase liquid. After stirring for 3 hours, after the sodium alginate fully forms a gel, it is tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com