Premixed wheat flour for making steamed bread contg. rich dietary fiber, and its prodn. method

A technology of dietary fiber steamed bread and premixed powder, which is applied in food science, baking, dough processing, etc., can solve the problems of steamed bread quality deterioration, achieve the effects of simplifying the production process, enhancing functionality, and increasing specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

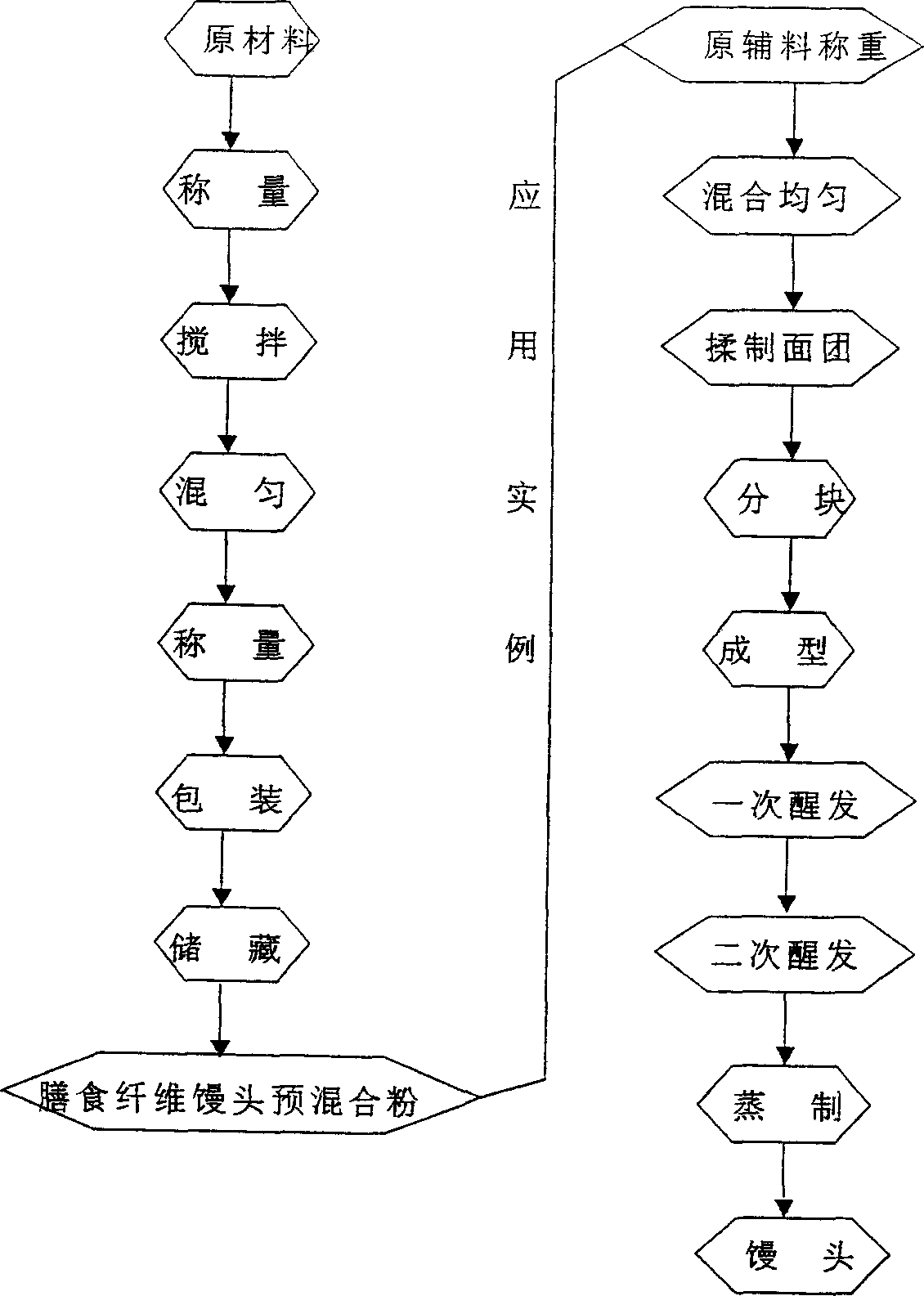

Method used

Image

Examples

Embodiment 1

[0018] In the embodiment of the present invention, take medium-gluten wheat flour: 86 parts; almond powder: 5.5 parts; almond skin powder after baking: 6.87 parts; active dry yeast: 1.5 parts; sodium bicarbonate: 0.1 part; : 0.03 parts. Mix evenly in the mixing tank according to the proportion at room temperature, the speed of the mixer is: 100 rpm; then weigh and pack according to the packaging standard, and it is recommended to refrigerate and store to be the finished product of special flour. Refrigeration temperature: 0°C.

[0019] In the embodiment, take premixed powder: 55 parts and warm water: 45 parts, mix evenly, and knead the dough repeatedly before fermentation. The number of times of kneading is preferably 10 times. After kneading, put it in 38 ° C and 80% humidity Ferment in a constant temperature and humidity box for 45 minutes, and the molded steamed bread embryos are placed in a constant temperature and humidity box at 38°C and a humidity of 80% to proof for 1...

Embodiment 2

[0022] In the embodiment of the present invention, take medium-gluten wheat flour: 88 parts; almond powder: 4.5 parts; almond peel powder after baking: 5.87 parts; active dry yeast: 1.5 parts; sodium bicarbonate: 0.1 part; : 0.03 parts. Mix wheat flour, almond flour, roasted almond skin powder, active dry yeast, sodium bicarbonate, and cellulase in a mixing tank in proportion at room temperature. The speed of the mixer is: 110 rpm; Weighing, packaging, it is recommended to store in cold storage is the finished product of special flour. Refrigeration temperature: 2°C.

[0023] In the embodiment, take premixed powder: 60 parts and warm water: 40 parts, mix evenly, and knead the dough repeatedly before fermentation, the number of times of kneading is preferably 11 times, and put it in 38°C and humidity 80% after kneading Ferment in a constant temperature and humidity box for 45 minutes, and the molded steamed bread embryos are placed in a constant temperature and humidity box a...

Embodiment 3

[0026] In the embodiment of the present invention, take medium-gluten wheat flour: 90 parts; almond powder: 3.37 parts; almond peel powder after baking: 5 parts; active dry yeast: 1.5 parts; sodium bicarbonate: 0.1 part; : 0.03 parts. Mix wheat flour, almond flour, roasted almond skin powder, active dry yeast, sodium bicarbonate, and cellulase in a mixing tank at room temperature. The speed of the mixer is 120 rpm; Weighing, packaging, it is recommended to store in cold storage is the finished product of special flour. Refrigeration temperature: 4°C.

[0027] In the embodiment, take premixed powder: 65 parts and warm water: 35 parts, mix evenly, and knead the dough repeatedly before fermentation, the number of times of kneading is preferably 12 times, and put it in 38°C and humidity 80% after kneading. Ferment in a constant temperature and humidity box for 45 minutes, and the molded steamed bread embryos are placed in a constant temperature and humidity box at 38°C and a hum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com