Welding structure and welding method for aluminum accumulator and heat exchanger

A technology of welded structure and aluminum accumulator, applied in heat exchange equipment, welding equipment, evaporator/condenser, etc., can solve the problems of poor welding, supply, difficult positioning of stainless steel casing 8, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

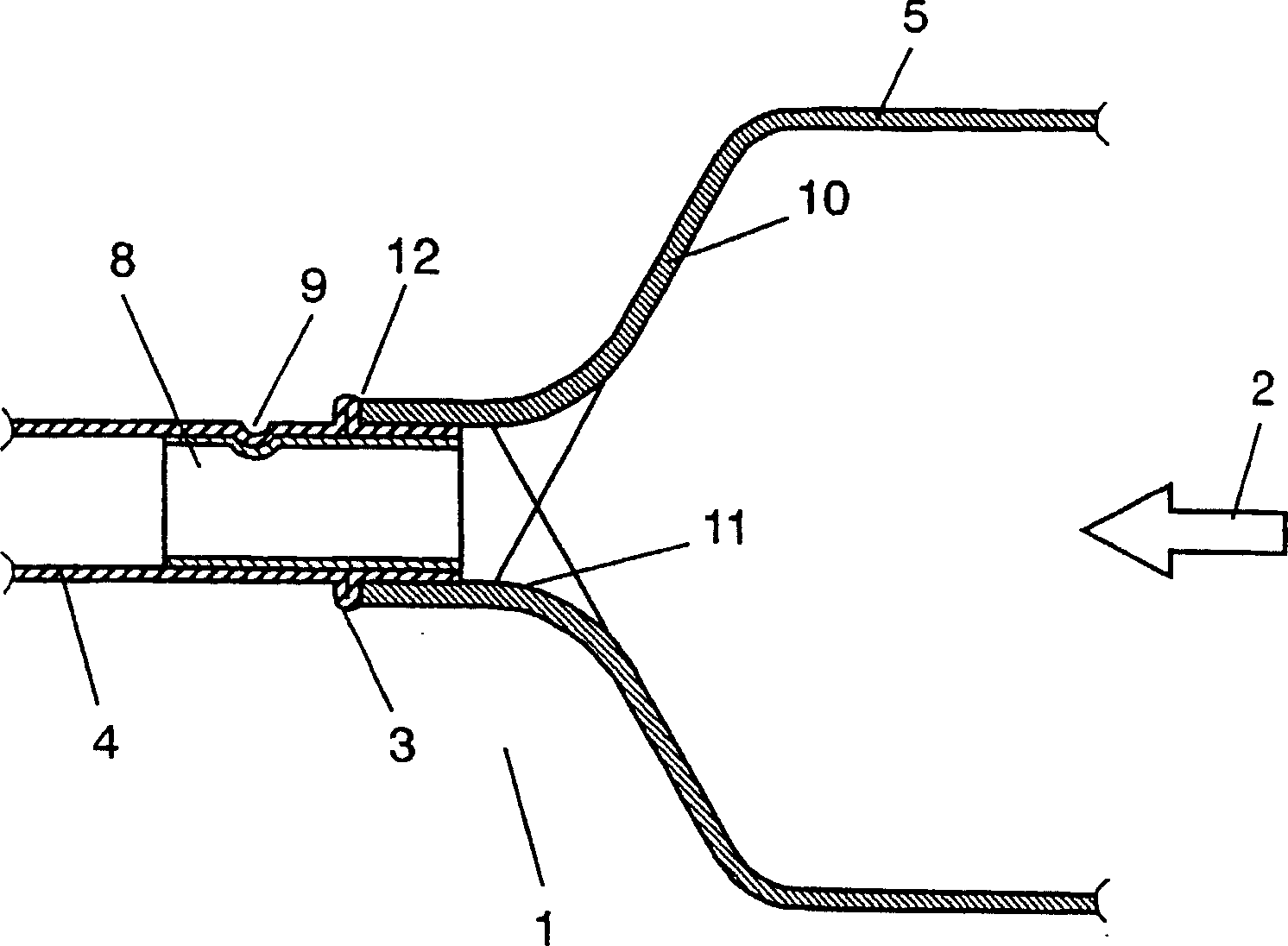

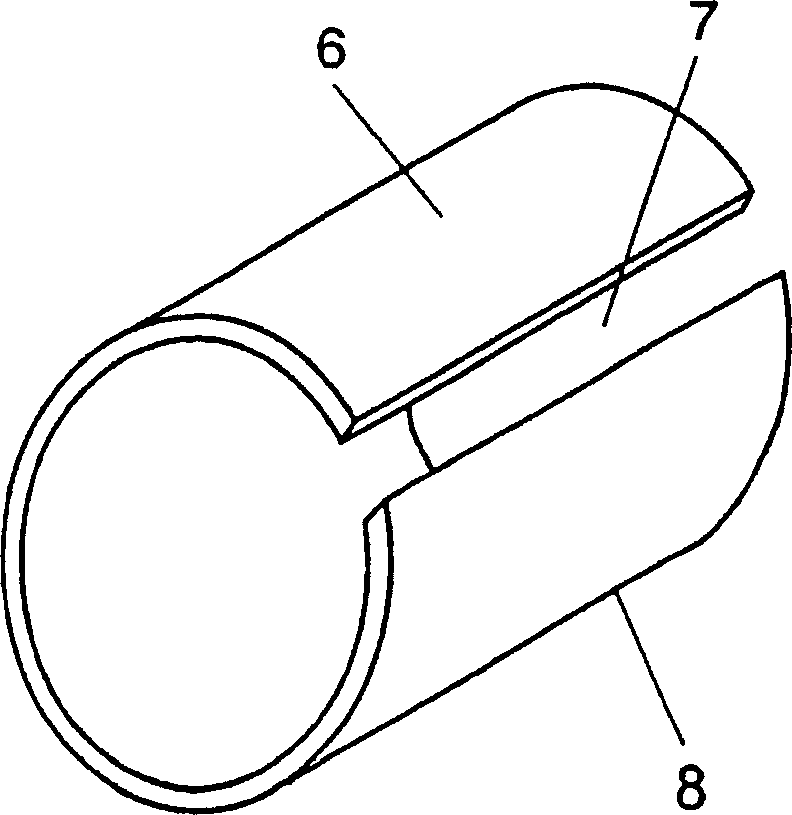

[0037] figure 1 It is a sectional view of the welded structure of the aluminum accumulator according to Embodiment 1 of the present invention, figure 2 It is the perspective view of the stainless steel casing of the same embodiment. figure 1 , figure 2 Among them, the welded structure 1 of the aluminum accumulator is composed of an aluminum conduit 4, an aluminum accumulator 5, and a stainless steel sleeve 8, wherein the aluminum conduit 4 is used in the outlet of an accumulator used in a freezing system such as a refrigerator, It is a heat transfer tube in which the refrigerant 2 flows, and has a weld bead processing part 3; the aluminum liquid receiver 5 has the following functions, that is, the liquid refrigerant is stored, and the liquid refrigerant is not directly sent to the compressor (not diagram) flows, but is utilizing a heat exchanger (using Figure 5 After the heat load of explaining later) it is vaporized, send into compressor; The stainless steel sleeve 8...

Embodiment approach 2

[0047] image 3 It is a cross-sectional view of the welded structure of the aluminum accumulator according to Embodiment 2 of the present invention, Figure 4 It is the perspective view of the stainless steel casing of the same embodiment. image 3 , Figure 4 Among them, the welded structure 1 of the aluminum accumulator is composed of an aluminum conduit 4, an aluminum accumulator 5, and a stainless steel sleeve 8, wherein the aluminum conduit 4 is used in the outlet of an accumulator used in a freezing system such as a refrigerator, It is a heat transfer tube in which the refrigerant 2 flows, and has a weld bead processing part 3; the aluminum liquid receiver 5 has the following functions, that is, the liquid refrigerant is stored, and the liquid refrigerant is not directly sent to the compressor (not diagram) flows, but is utilizing a heat exchanger (using Figure 5 After the heat load of explaining later) it is vaporized, send into compressor; The stainless steel slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com