Ngatively pressurized sampling three-dimensional chip capillary array electrophoresis system

A capillary array and capillary electrophoresis technology, which is applied in the direction of material analysis, measuring device, and instrument by electromagnetic means, can solve the problems of long sampling time, expensive equipment, complex structure, etc., and achieve fast sampling speed and reduce manufacturing costs. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

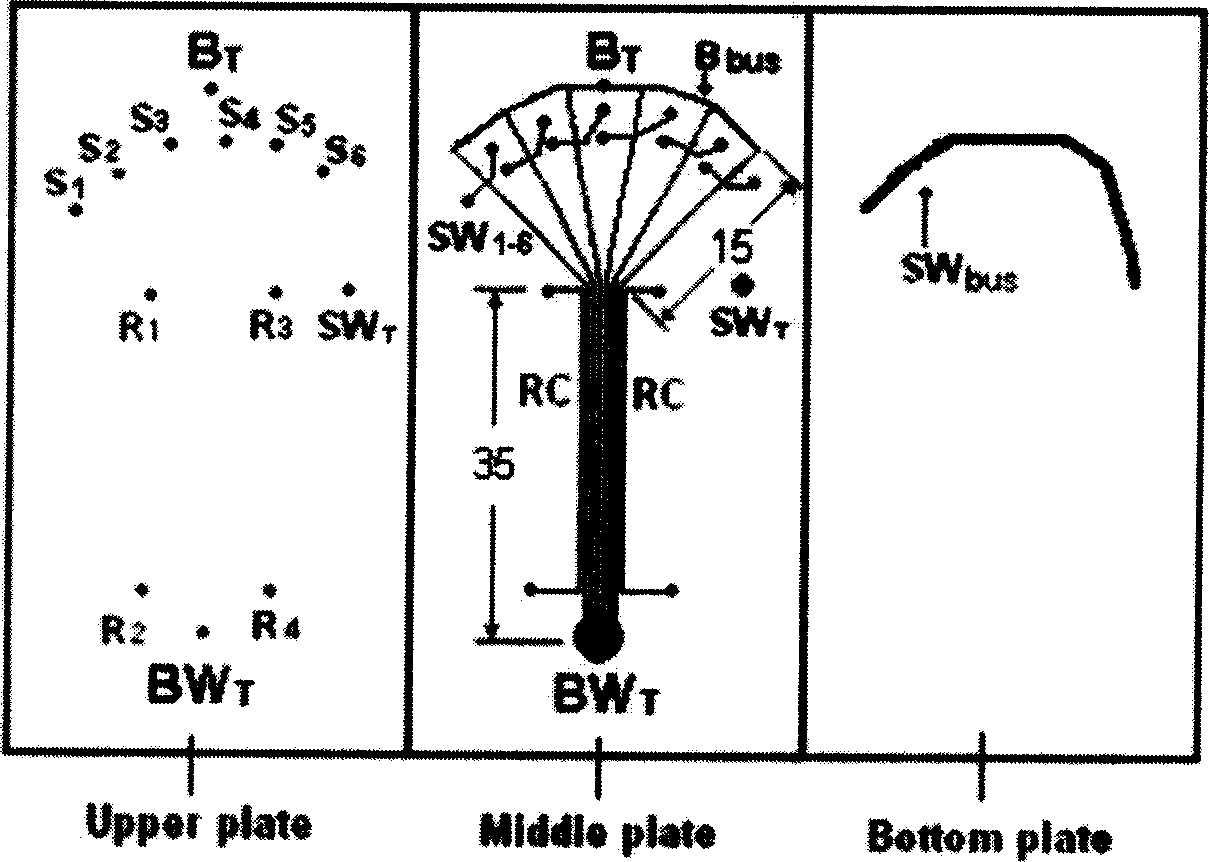

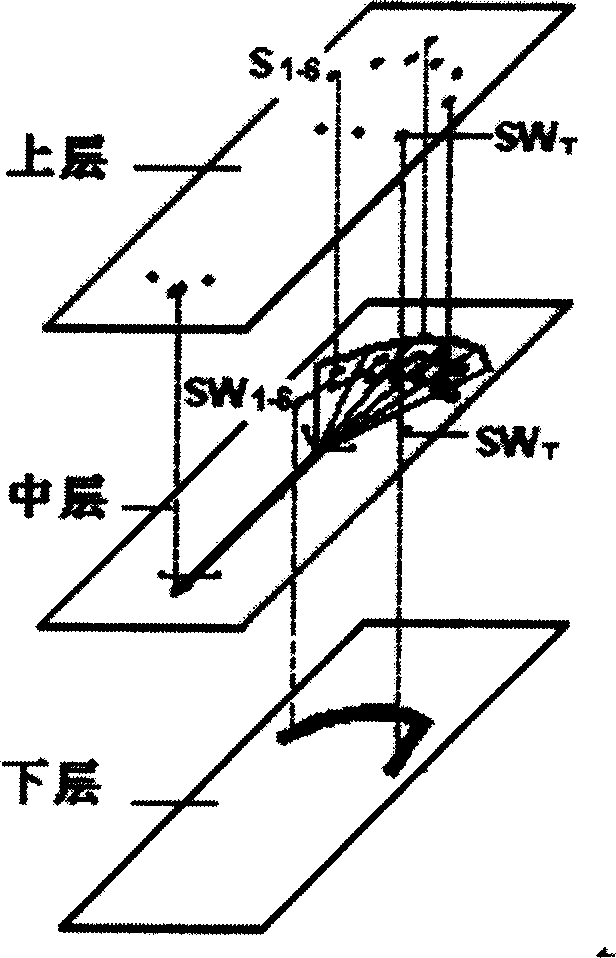

Embodiment 1

[0023] The three-dimensional capillary array electrophoresis microchip 1 provided in the present invention is made of a three-layer substrate, and the substrate material can be glass, quartz or high molecular polymer. Drill holes at appropriate positions on the upper substrate as a common buffer pool B for the three-dimensional capillary array electrophoresis microchip T , public buffer waste pool BW T , each sample solution pool S 1 -S n The outlet and common sample waste reservoir SW Timports. On the substrate in the middle layer, a channel network containing a large number of capillary electrophoresis separation units is processed, and each separation unit is composed of a separation swimming lane and a sample injection channel. The inlets of these separation lanes pass through a common buffer channel B bus Connect together, and pass through the small hole at the corresponding position of the upper substrate and the common buffer pool B T Connected together; the outle...

Embodiment 2

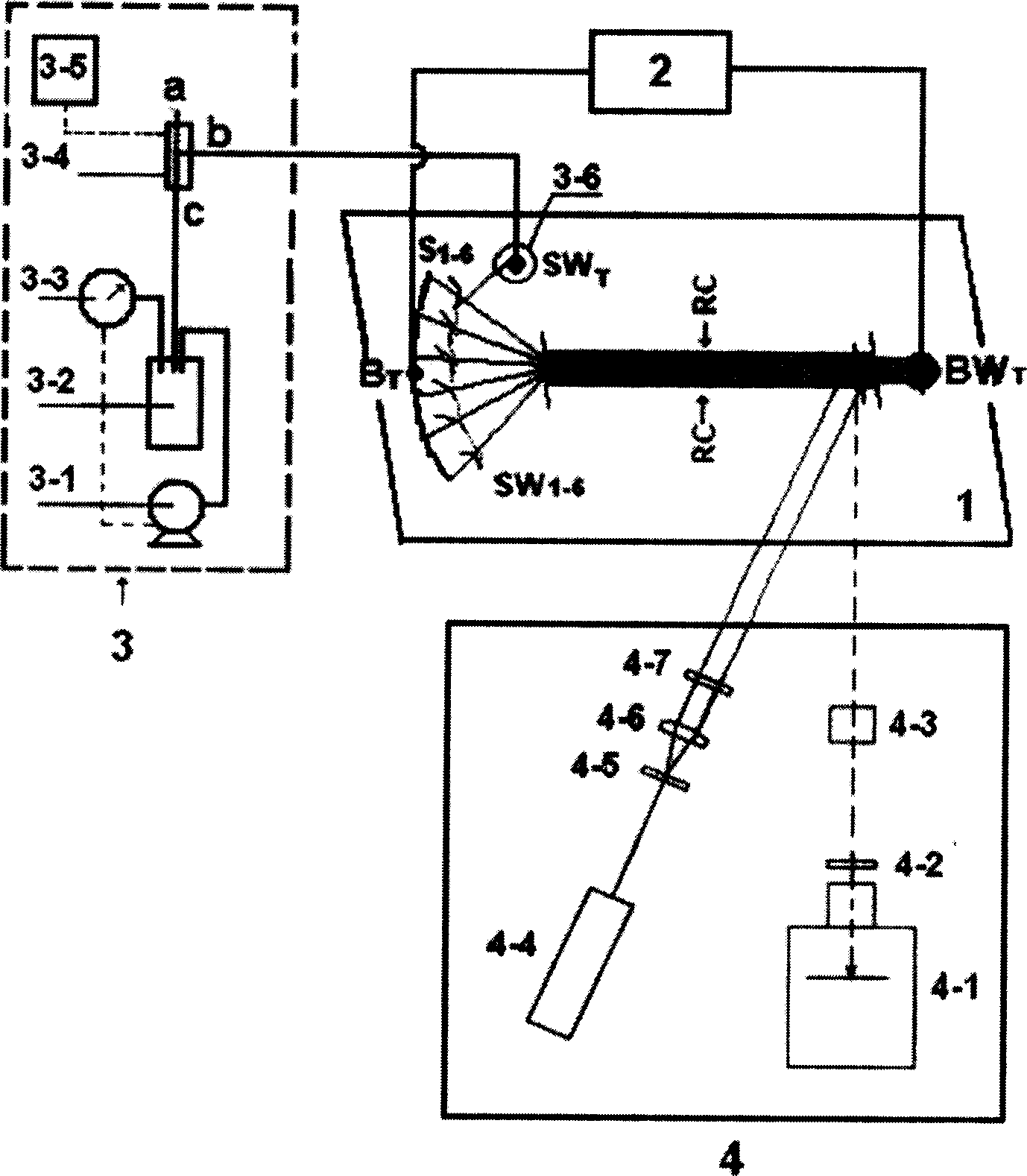

[0026] Example 2: Parallel separation and determination of multiple samples using a three-dimensional six-lane capillary chip array electrophoresis system with negative pressure injection

[0027] Negative pressure injection three-dimensional six-lane capillary chip array electrophoresis system such as image 3 As shown, it consists of a three-dimensional six-lane glass capillary electrophoresis microchip 1, a high-voltage DC power supply 2, a negative pressure sampling device 3 and a laser-induced fluorescence detector 4. For the negative pressure sampling device 3, refer to the invention patent (patent application number: 200610048906.6) , is made up of miniature vacuum pump 3-1, vacuum bottle 3-2, electrical contact vacuum gauge 3-3, three-way solenoid valve 3-4, timer 3-5 and interface 3-6. The laser-induced fluorescence detector is composed of a charge-coupled detection device (4-1) of CCD for short, a color filter (4-2, 4-7), a laser (4-4) and a lens (4-3, 4-5, 4 -6) Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com