Fiber-treating liquid, modified fiber cloth, and process for producing the same

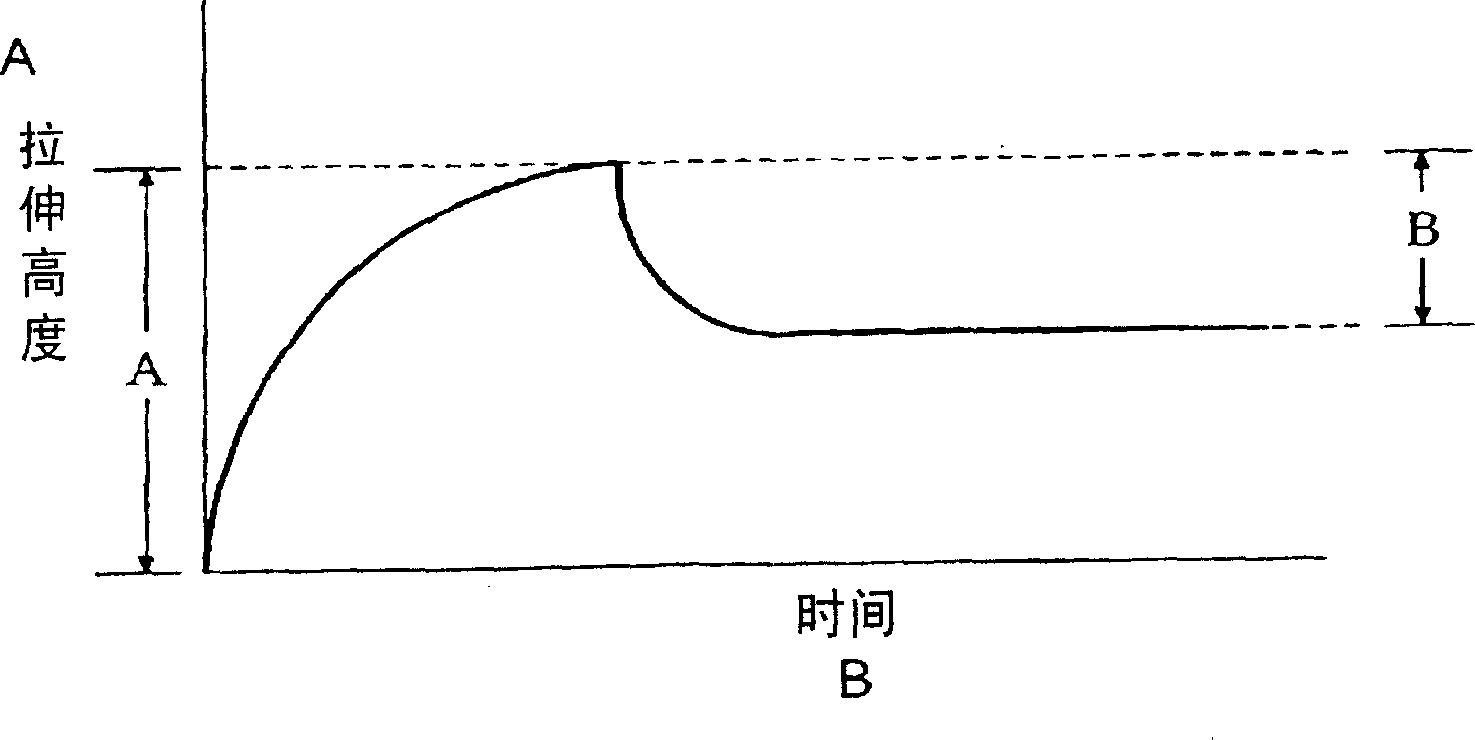

A technology for modifying fibers and fiber fabrics, applied in fiber processing, fabrics, textiles and papermaking, etc., can solve problems such as difficulty in bringing durability, high adsorption capacity, inability to skin softness, elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

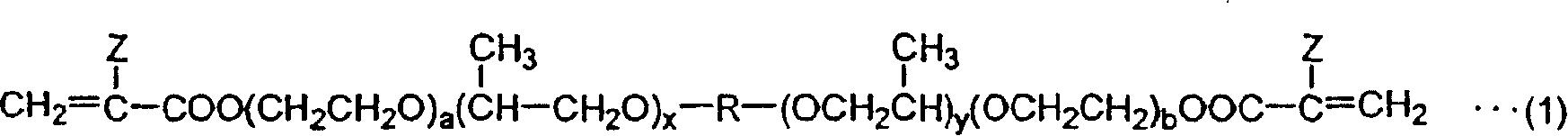

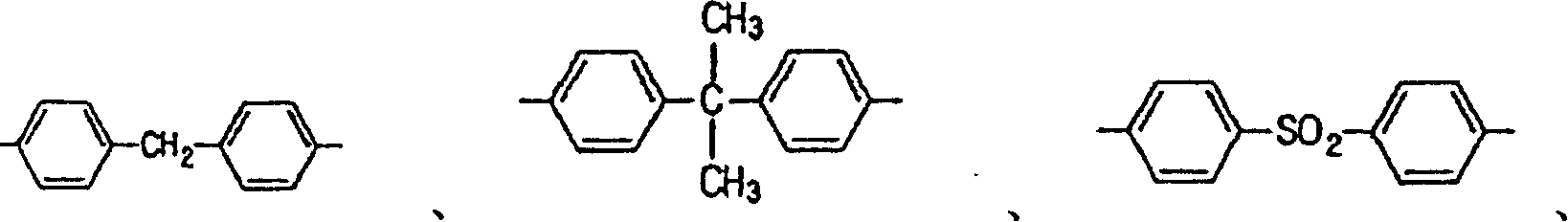

Method used

Image

Examples

Embodiment 1

[0165] Using conventional methods, the quality of the billet used is 110g / m 2 The pongee fabric of polyester false-twisted textured yarn is relaxed, scoured, pre-set, alkali weight-reducing processing, and dyed in sequence. This fiber fabric is used as a base material and subjected to modification treatment.

[0166] Fiber treatment liquids having the compositions shown in Table 2 were prepared and applied to fiber fabrics by exhaust dyeing. The wet pickup rate was set at 60% by mass. Thereafter, a wet heat treatment was performed for 5 minutes in steam at 110° C. and 98% RH to perform polymerization. After the polymerization reaction is completed, cleaning and post-processing are performed. The resulting modified fiber fabrics were evaluated.

[0167] [Table 2]

[0168]

Embodiment 2

[0170] The quality of the billet used is 150g / m 2 Polyester false-twisted textured yarn to make 28-gauge double rib knitting. With respect to this polyester knitted fabric, loosening, scouring, presetting, and dyeing are sequentially performed by a conventional method. This fiber fabric is used as a base material and subjected to modification treatment.

[0171] As in Example 1, the fiber treatment liquid was applied to the fiber fabric by the exhaust dyeing method. The squeeze rate was set to 80% by mass. Then, after drying at 120° C. for 3 minutes, a wet heat treatment was performed for 60 minutes in steam at 105° C. and 97% RH to perform polymerization. After the polymerization reaction is completed, post-treatment is performed. The resulting modified fiber fabrics were evaluated.

Embodiment 3

[0191] The quality of the billet is 100g / m 2 The high-quality nylon taffeta is scouring, pre-shaped, and dyed in sequence using conventional methods. This fiber fabric is used as a base material and subjected to modification treatment.

[0192] Fiber treatment liquids having the compositions shown in Table 8 were prepared and applied to fiber fabrics by exhaust dyeing. The squeeze rate was set at 50% by mass. Thereafter, a wet heat treatment was performed for 5 minutes in steam at 105° C. and 98% RH to perform polymerization. After the polymerization reaction is completed, washing, drying, and post-processing are performed. The resulting modified fiber fabrics were evaluated.

[0193] [Table 8]

[0194]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com