TAB tape carrier

A carrier and strip-shaped technology, which is applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of difficult to ensure the gap between semiconductor elements and TAB tape carriers, the gap of sealing resin, and the difficulty of filling and sealing Resin and other problems, to achieve a firm connection, improve adhesion, and inhibit the effect of sinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

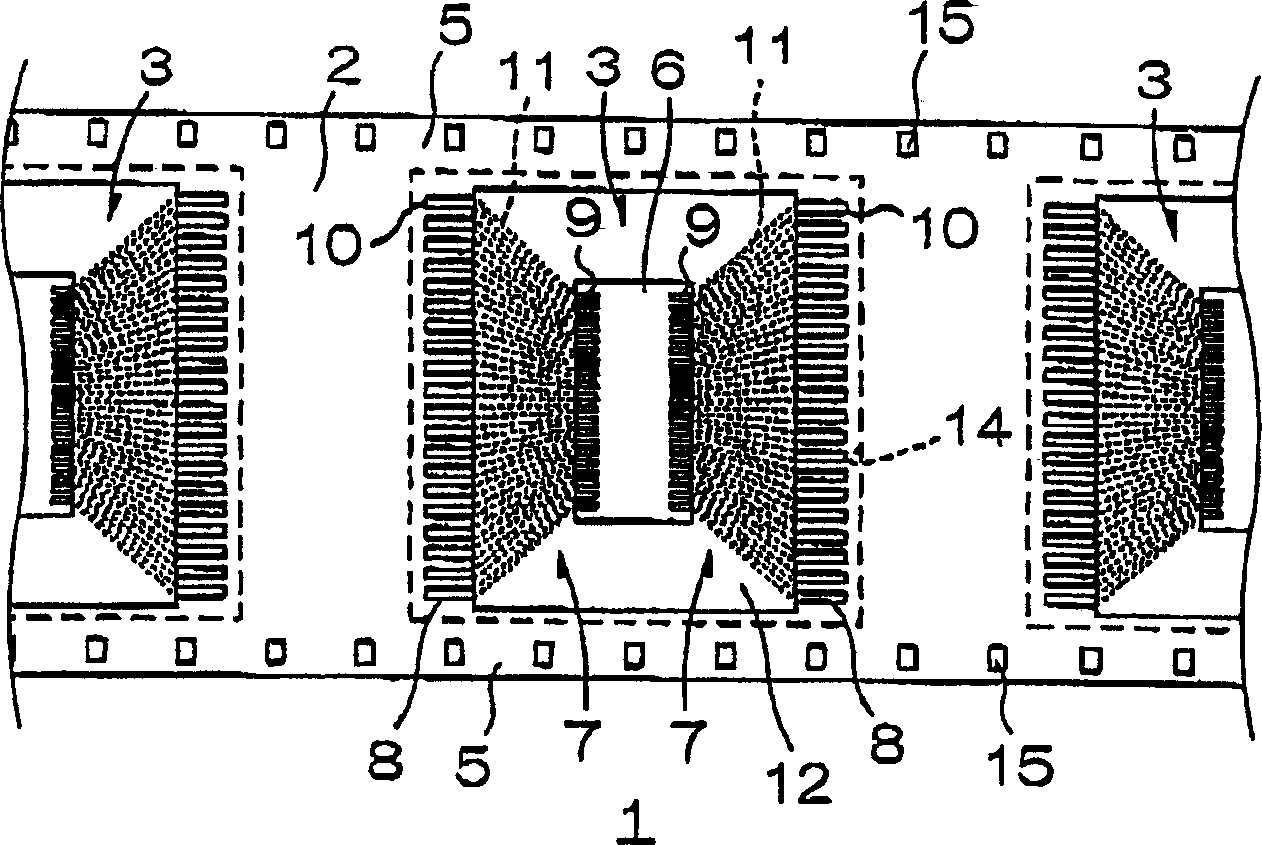

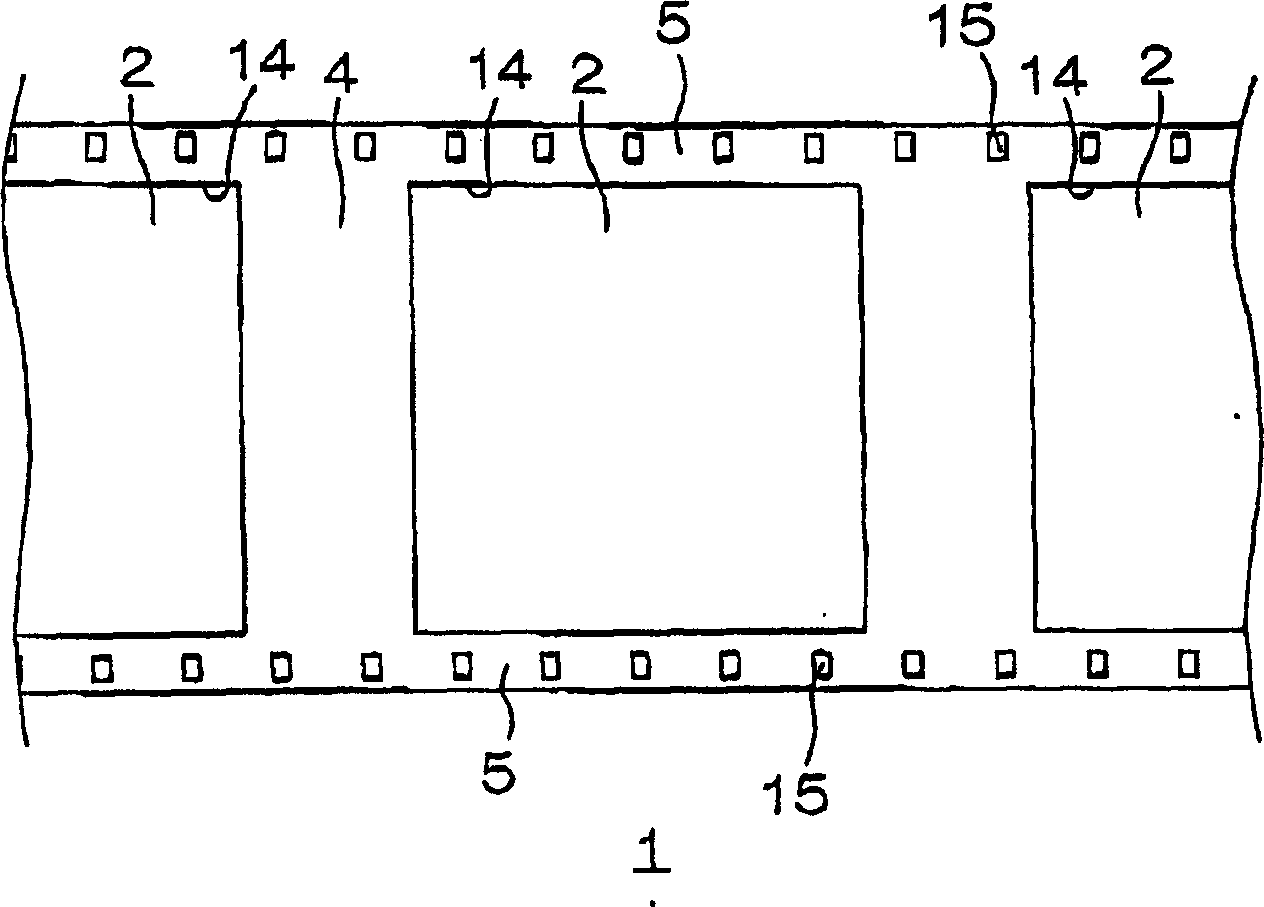

[0091] In this Example 1, four rows of tape carriers for TAB with a width of 48 mm were simultaneously produced on a reinforcement layer with a width of 250 mm.

[0092] First, as a reinforcing layer, prepare stainless steel (SUS304) with a thickness of 20 μm (reference Figure 4 (a)), on this reinforcing layer, coat polyamic acid resin solution, make it heat curing after drying, form the thermosetting polyimide resin layer that thickness is 20 μm (refer to Figure 4 (b)). In addition, the coefficient of linear expansion of this thermosetting polyimide resin layer was 20 ppm / °C.

[0093] Next, on the thermosetting polyimide resin layer, apply a thermoplastic polyimide resin solution mainly composed of aliphatic polyimide, and dry it to form a thermoplastic polyimide resin with a thickness of 1 μm. layer (reference Figure 4 (c)). In addition, the glass transition temperature of this thermoplastic polyimide resin layer was 300 degreeC.

[0094] In this way, an insulating b...

Embodiment 2、3 and comparative example 1

[0103] A tape-shaped carrier for TAB was obtained in the same manner as in Example 1, except that the thickness of the thermoplastic polyimide resin layer was 3 μm in Example 2, 4 μm in Example 3, and 5 μm in Comparative Example 1.

[0104] evaluate

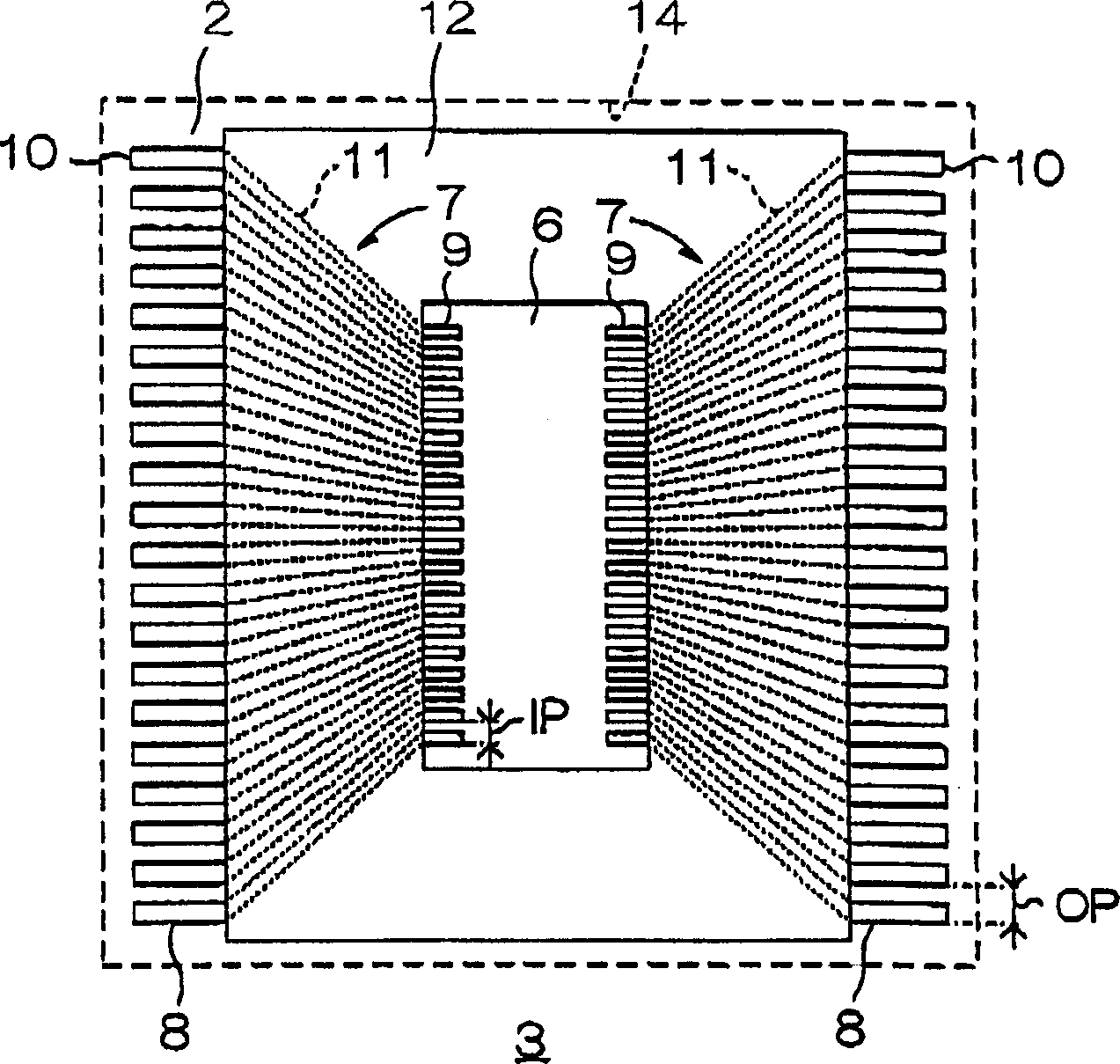

[0105] In the mounting portion of the tape carrier for TAB obtained in Examples 1 to 3 and Comparative Example 1, a semiconductor element provided with gold bumps was mounted. In the mounting of the semiconductor element, gold bumps are opposed to inner leads covered with tin plating, and crimping is performed at a mounting temperature (temperature of crimping equipment) of 325°C and a mounting load of 130N. After crimping, the amount of dishing of the insulating base layer was measured. The results are shown in Table 1.

[0106] After that, the gap between the semiconductor element and the mounting portion of the tape carrier for TAB is filled with a liquid primer and the sealing resin (liquid Anta-fil sealing resin) is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com