Bioabsorbable polymeric granular porous bone filling material and production method thereof

A bioabsorption and filling material technology, applied in dental preparations, tissue regeneration, pharmaceutical formulations, etc., can solve the problems of low crushing efficiency, difficulty in industrial crushing, and inability to obtain granular materials, and achieve high bioabsorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

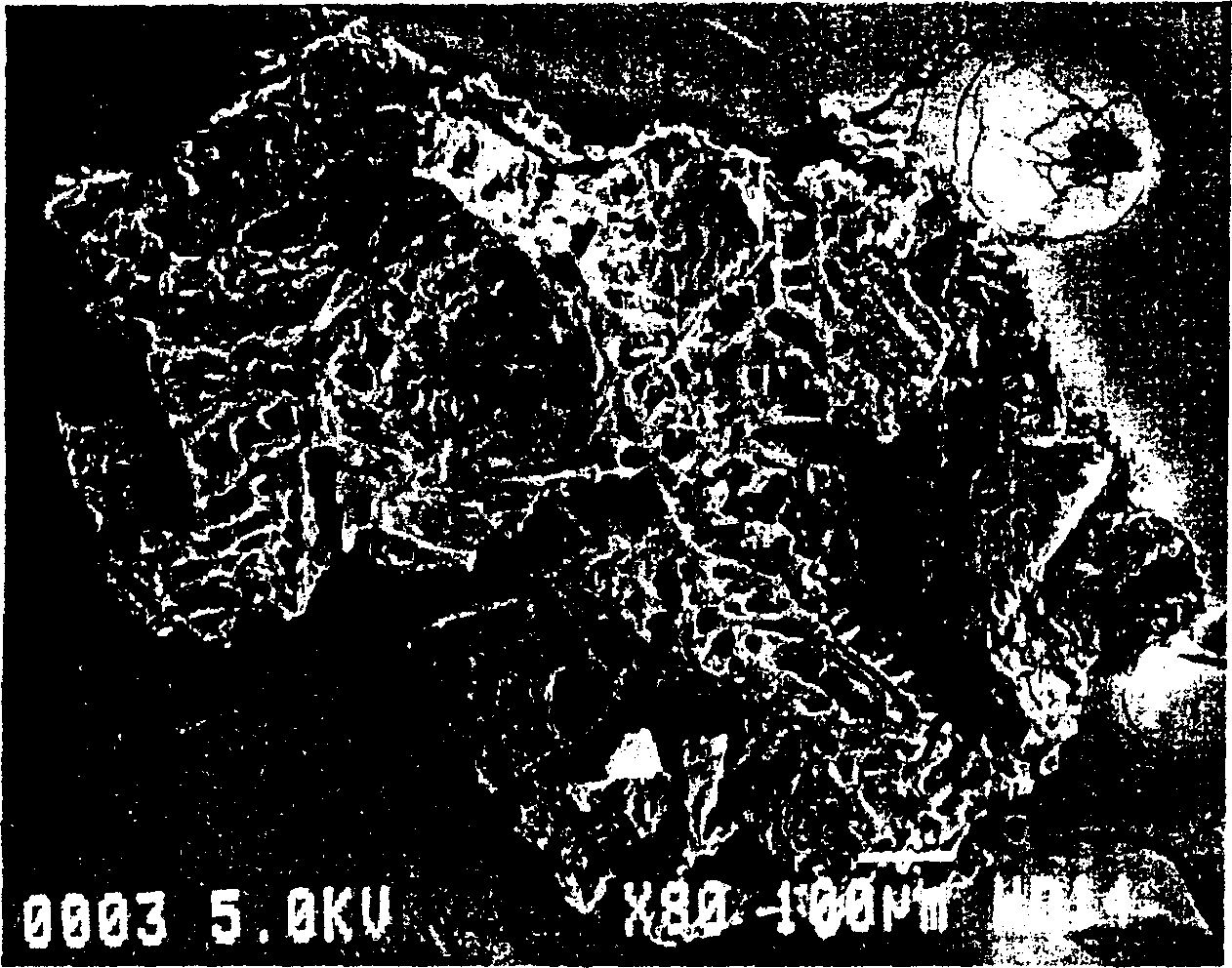

Image

Examples

Embodiment 1

[0028] A polymer material containing sodium chloride that is approximately uniformly mixed is obtained by adding a copolymer of lactic acid and glycolic acid (lactic acid: glycolic acid=75:25, with a weight average molecular weight of about 250,000) in dioxane Medium to concentration of 12% by weight, use a stirrer to stir to dissolve, sodium chloride powder (particle size is 300-700 μm) and dioxane solution dissolved in lactic acid and glycolic acid copolymer are approximately uniformly mixed to The concentration of sodium chloride is about 1.18g / cm 3 , pour it into a mold, use a refrigerator (MDf-0281AT produced by Sanyo Electric Corporation) to freeze at -30 ° C, and then use a vacuum dryer (DP43 produced by Yamato Scientific Corporation) to dry under reduced pressure for 48 hours to remove oxygen Heterocyclohexane. Then, by cutting the polymer into small pieces, pulverizing the small pieces using a planetary ball mill for 50 minutes, adding the pulverized polymer to the f...

Embodiment 2

[0030] Obtain the polymeric material that contains the sodium chloride that mixes approximately uniformly by following method: polyglycolic acid (weight average molecular weight is about 200000) is added in the dichloromethane to concentration and is 9% by weight, uses stirrer to stir to make it dissolve, and Pour the dichloromethane solution of polyglycolic acid into the mold that has been added with sodium chloride powder (particle size 300-700 μm) to a sodium chloride concentration of about 1.18g / cm 3 , using a refrigerator (MDf-0281AT produced by Sanyo Electric Corporation) to freeze at -30°C, and then drying under reduced pressure using a vacuum dryer (DP43 produced by Yamato Scientific Corporation) for 48 hours to remove dichloromethane. Then, by cutting the polymer into small pieces, pulverizing the small pieces using a planetary ball mill for 20 minutes, adding the pulverized polymer to a flask, adding distilled water to the flask, stirring to remove sodium chloride, an...

Embodiment 3

[0032] Obtain the polymer material that contains the potassium chloride of homogeneous mixing by following method: the copolymer of lactic acid and glycolic acid (lactic acid: glycolic acid=75:25, weight average molecular weight is about 250000) joins dioxane Medium to concentration of 12% by weight, use a stirrer to stir to dissolve it, pour the dioxane solution of lactic acid and glycolic acid copolymer into the mold that has been added with potassium chloride powder (particle size is about 400 μm) To potassium chloride concentration of about 1.08g / cm 3 , was frozen at -30°C using a refrigerator (MDf-0281AT manufactured by Sanyo Electric Corporation), and then dried under reduced pressure using a vacuum dryer (DP43 manufactured by Yamato Scientific Corporation) for 48 hours to remove dioxane. Then, cut the polymer into small pieces, pulverize the small pieces for 50 minutes using a planetary ball mill, add the pulverized polymer into a flask, add distilled water into the fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com