Transistor with quantum dots in its tunnelling layer

A quantum dot and body technology, applied in the field of semiconductor components, can solve the problems of complex, expensive, difficult to manufacture tunnel oxide layers, etc., and achieve the effect of simplifying the manufacturing process and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example of Example 1

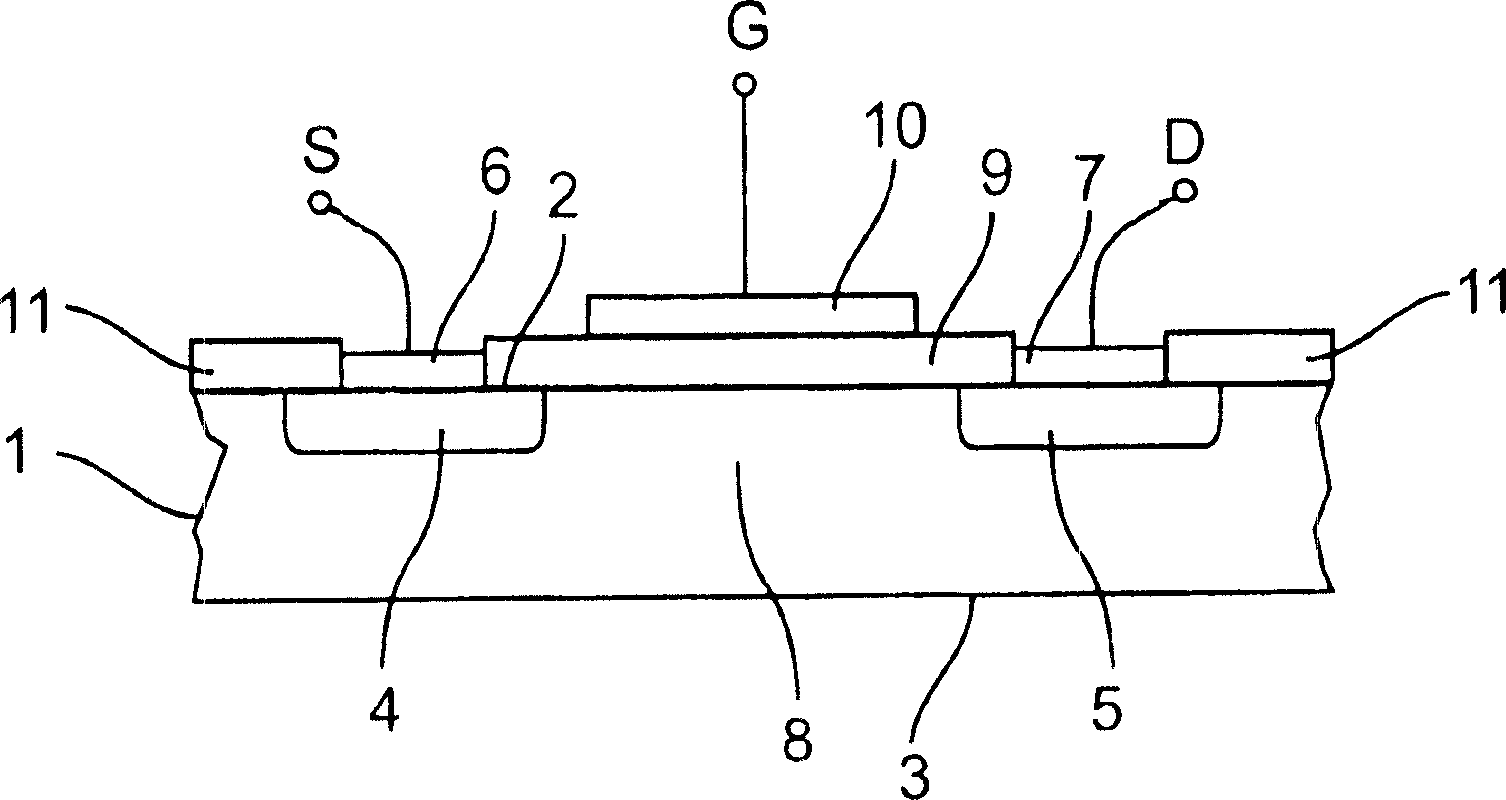

[0035] To produce the semiconductor component according to the invention, the n-conductive source region 4 and the n-conductive drain region 5 are first produced by ion-implanting phosphorous into the boron-doped silicon semiconductor body 1 . Then, by means of photolithography, source electrodes 6 and drain electrodes 7 made of Al doped with 0.5 wt. % Cu are applied. By spin coating will contain TiO 2 / SiO 2 A suspension of quantum dots is applied between the two electrodes 4, 5 and allowed to consolidate under an inert atmosphere at temperatures up to 300°C. The consolidated insulating layer 9 contains SiO embedded in 2 5 nm diameter TiO in the matrix 2 quantum dots. After cooling to room temperature, a gate electrode 10 of Al is applied to the insulating layer 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com