Process for preparing SiO2 mesoporous material-cadmium sulfide composition nano material

A technology of mesoporous materials and silicon dioxide, which is applied in the field of preparation of silica mesoporous materials-cadmium sulfide composite nanomaterials, can solve problems such as economical efficiency, low environmental protection, inability to ensure stable distribution, complicated procedures, etc., and achieve Good economy, good environmental friendliness, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] References Science 1998, 279, 548 reported the preparation of SBA-15: 2 grams of EO 20 PO 70 EO 20 (P123) Templating agent dissolved in 15 g H 2 O and 60 g of 2mol / L HCl in a mixed solution, stirred with a magnetic stirrer until clarified. Add 4.25 g of TEOS (orthoethyl silicate), stir for 24 hours, then move into a stainless steel reactor with a polytetrafluoroethylene liner, and age at 373K for 48 hours. Filtrate the precipitate, wash it with water, and dry it, then bake it at 823K for 6 hours to obtain a silica mesoporous material with a specific surface area of 696m 2 g -1 , the pore size is 6.12nm.

[0022] Take by weighing 7.61 grams (0.01mol) of thiourea and 1.14 grams (0.005mol) of cadmium chloride, dissolve in 50 milliliters of deionized water, weigh 1.2 grams (0.02mol) of SBA-15 mesoporous material and put it into the above solution for immersion, After stirring at room temperature for 12 hours, filter, rinse with deionized water and ethanol in turn, a...

Embodiment 2

[0028] The preparation steps of the SBA-15 mesoporous material are the same as in Example 1, and the CdS loading operation steps and immersion time are the same as in Example 1, but the amount of thiourea is increased to 15.22 grams (0.02mol), and the amount of cadmium chloride is increased to 2.28 Gram (0.005mol).

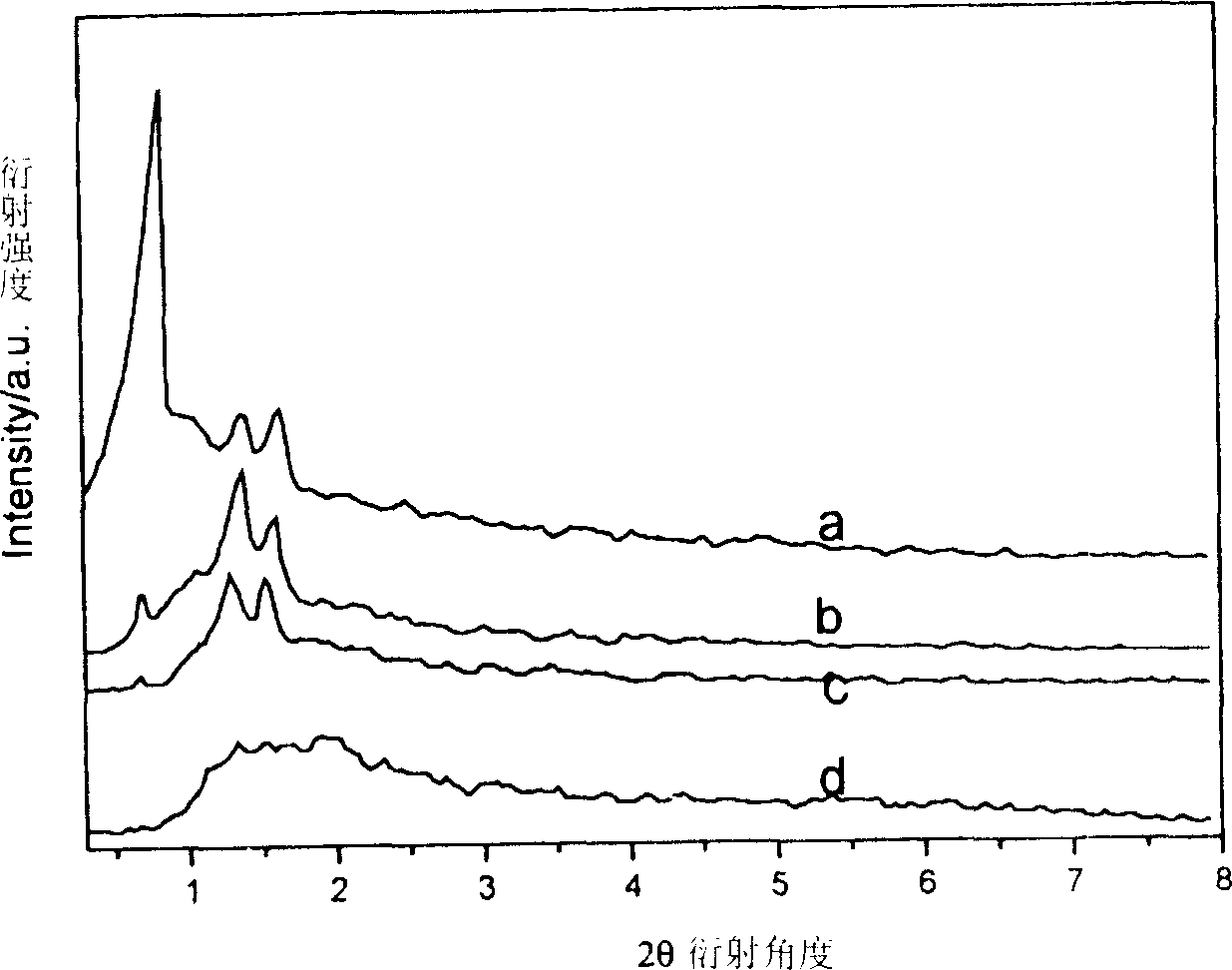

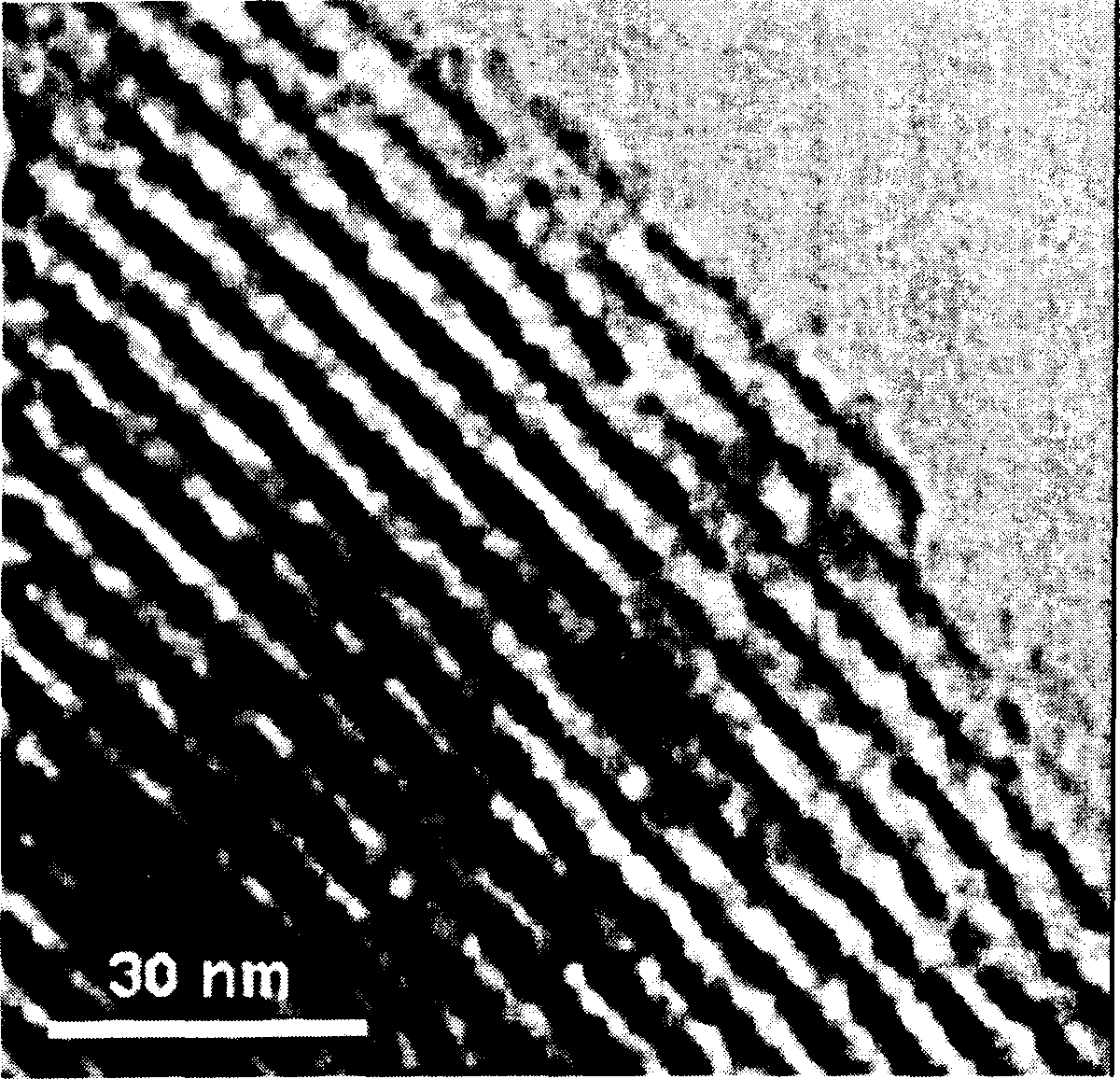

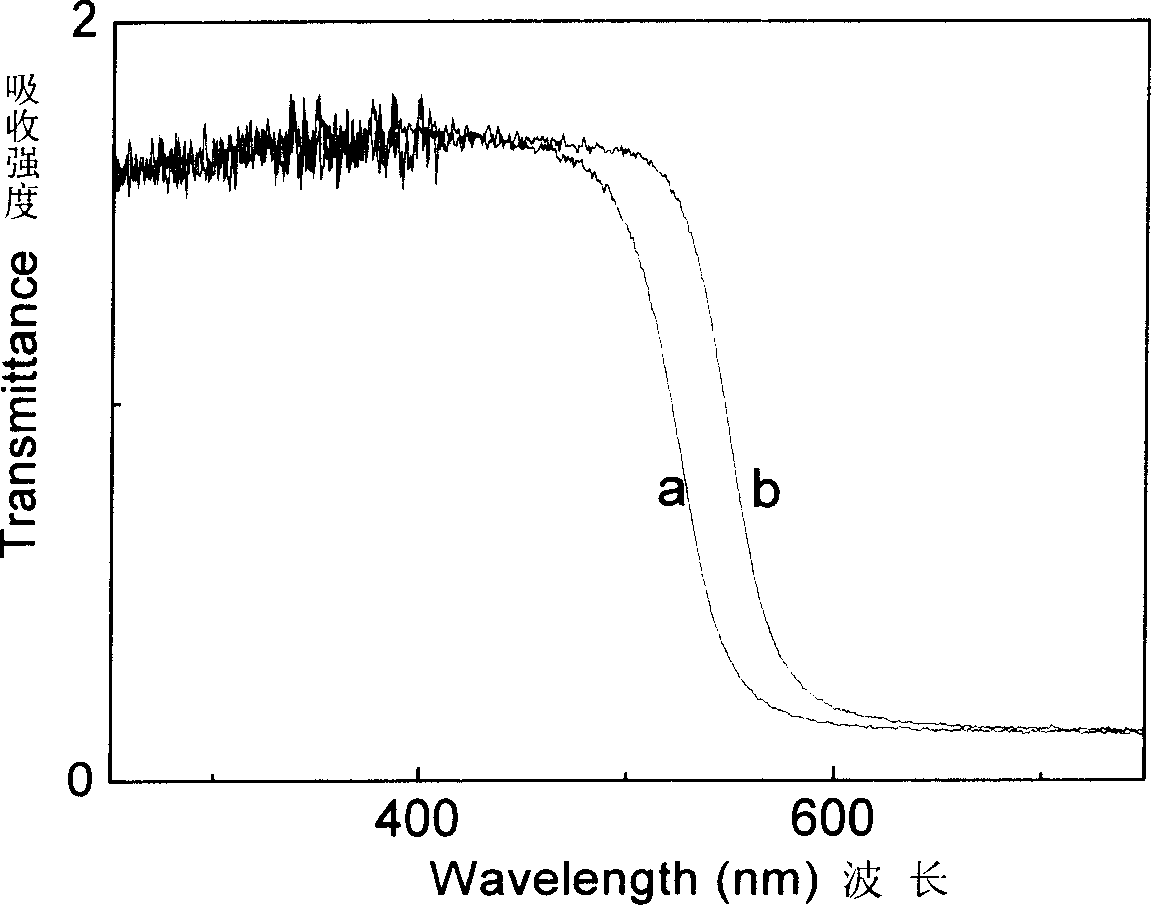

[0029] Now the small-angle X-ray diffraction pattern (XRD) of gained SBA-15-CdS nanocomposite material is as follows figure 1 c curve shown. It can be seen from the figure that when the concentration of CdS increases and the loading amount in the SBA-15 mesoporous material increases, the hexagonal phase pore structure of the SBA-15 mesoporous material is still maintained to a certain extent, but its order degree changes. declined to a certain extent. BET test shows that the specific surface of this embodiment gained SBA-15-CdS nanocomposite material is reduced to 402m 2 g -1 ; Pore diameter also decreased from 6.12nm to 5.38nm. However, HRTEM characterization...

Embodiment 3

[0031] The preparation step of SBA-15 mesoporous material is the same as Example 1, and the CdS loading operation step is the same as Example 1, but the amount of thiourea increases to 15.22 grams (0.02mol), and the amount of cadmium chloride increases to 2.28 grams (0.005 mol). mol); the immersion time was extended from 12 hours to 24 hours.

[0032] Now the small-angle X-ray diffraction pattern (XRD) of gained SBA-15-CdS nanocomposite material is as follows figure 1 d curve shown. It can be seen from the figure that as the immersion time prolongs, the loading of CdS in the SBA-15 mesoporous material continues to increase, and the pore order of the SBA-15 mesoporous material further decreases, and the structural characteristics of the hexagonal phase have basically been lost. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com