Coating process and equipment for spiral fluorescent tube

A lamp and spiral technology, applied in the field of powder-free powder coating process and equipment, can solve the problems of low utilization rate, high site requirements, affecting the appearance of the lamp tube, etc. requirements, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Such as image 3 , the powder coating process of the traditional spiral lamp tube fixes the lamp vertically on the machine table, and the powder slurry gathers at the inner bottom of the tube cavity under the action of gravity, and due to the relationship between the lead angle of the lamp tube, the powder slurry flows out slowly, so it is easy to Thick plaques formed on the bottom layer of the lumen.

[0028] Such as Figure 4 , U-shaped tube powder coating process, under the action of gravity, the powder slurry flows out evenly along the tube wall, and is dried by blowing, so that the phosphor powder is evenly attached to the tube wall, and there is no formation of thick spots .

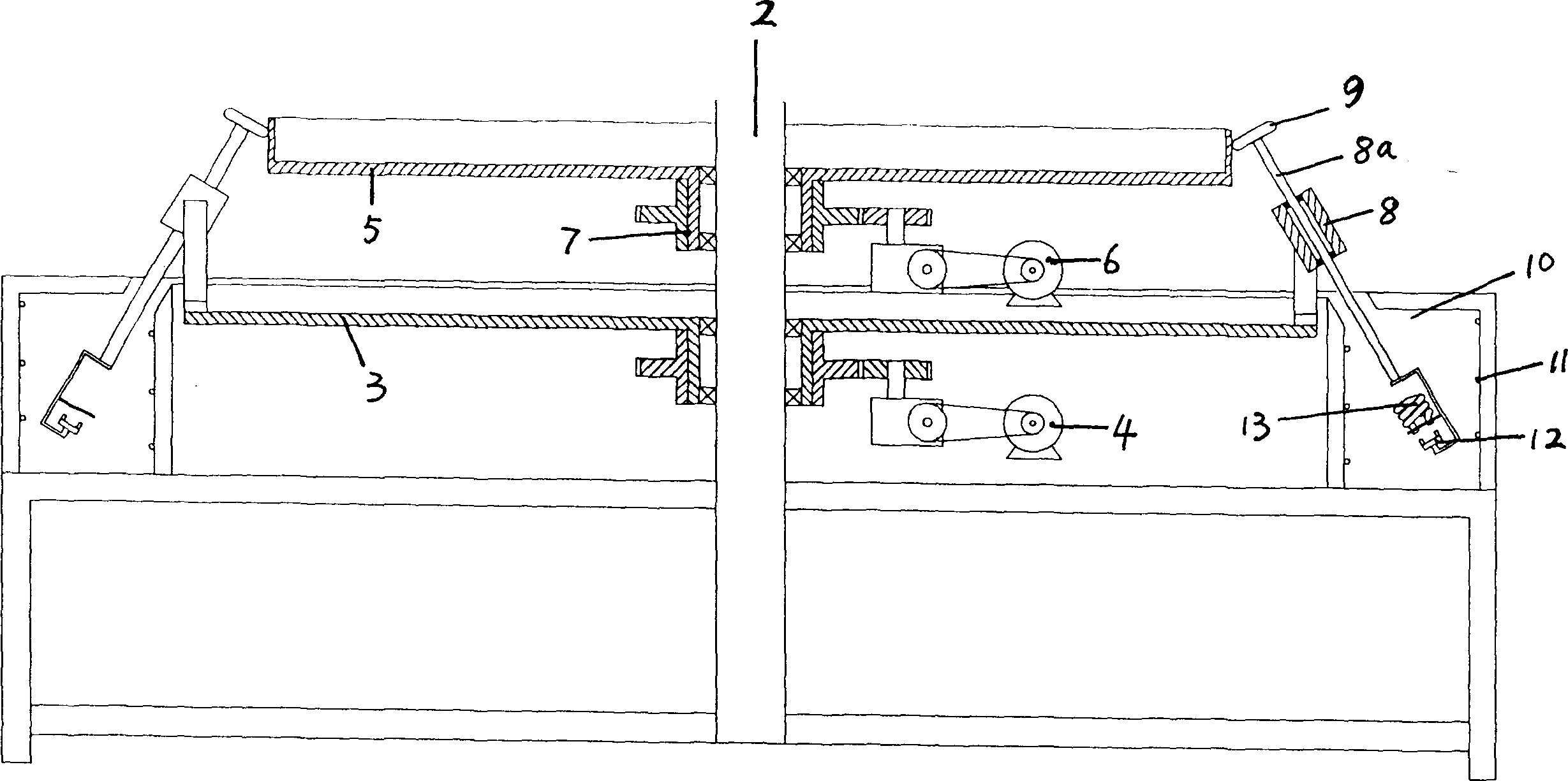

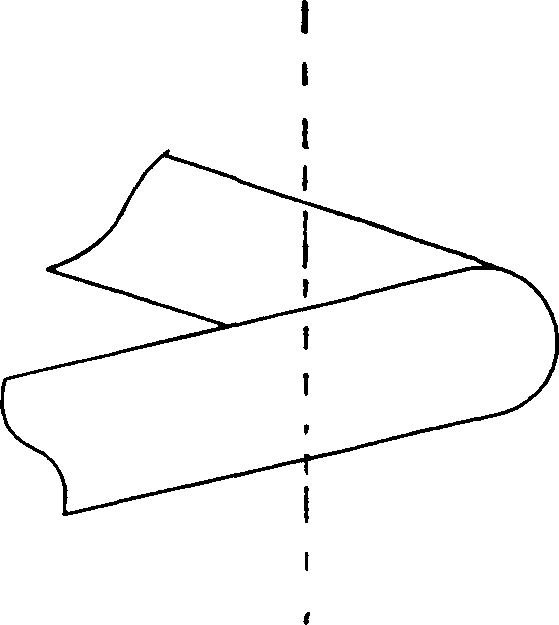

[0029] Such as Figure 5 , the present invention simulates the powder coating process of the U-shaped tube and designs a new spiral lamp tube powder coating process. Place the lamp tube at a certain angle of inclination, then the state of the slurry at the position where the tangent of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com