Smoke purifier of domestic refuse incinerator

A domestic waste incineration and flue gas purification technology, applied in incinerators, combined devices, combustion types, etc., can solve the problems of blocked return pipes, bag sticking, frequent load fluctuations, and high operating costs, so as to avoid blockage and wear , reduce operational failures, and lower quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

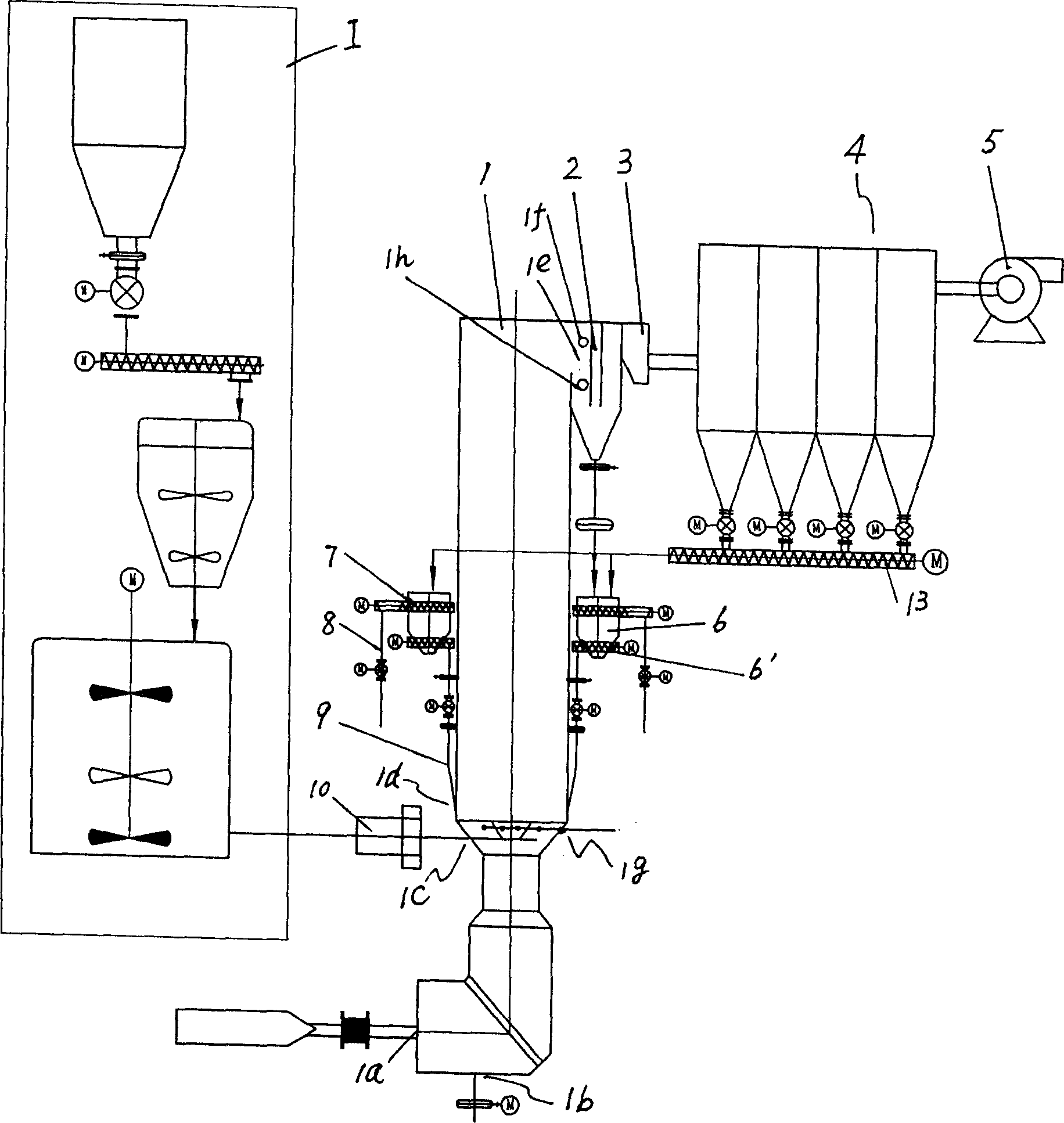

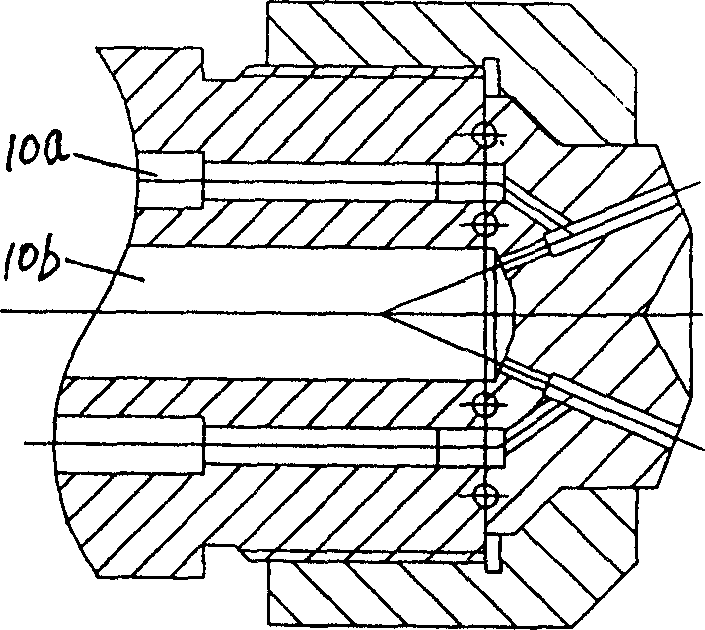

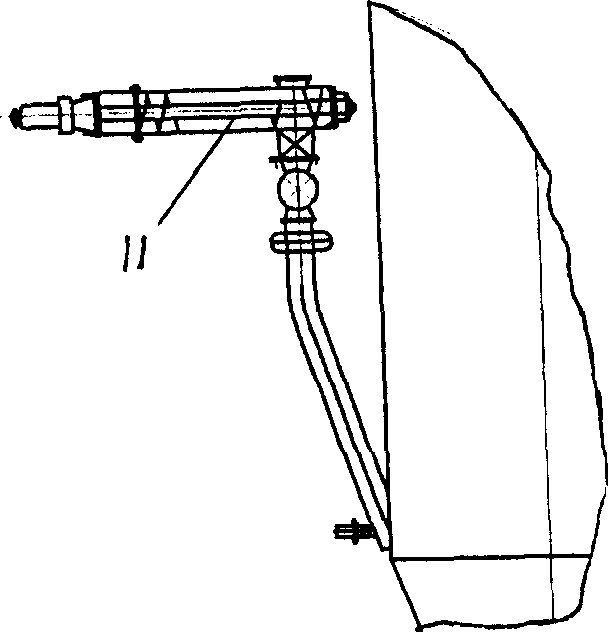

[0017] Embodiment 1, the structure of the flue gas purification device of the domestic waste incinerator of the present embodiment can be obtained from figure 1 Seen in, it contains a gas inlet 1a, slag outlet 1b, lime dry powder Ca(OH) 2The nozzle 1g, the reaction tower 1 of the flue gas outlet 1e, and the pre-dust collector 2, bag filter 4, and induced draft fan 5 connected in sequence to the flue gas outlet of the reaction tower. Wherein the bottom of the reaction tower 1 has a Venturi tube, that is to say, the bottom of the tower body has a constriction section that gradually reduces the cross-section from bottom to top and a diffusion section that gradually expands the cross-section upward, so that the flue gas can flow freely after low-resistance injection. Immediately change to a high speed and enter the reaction zone; the spout 1g of dry lime powder is arranged on the tower wall where the Venturi tube diffusion section is located; the present embodiment device is also ...

Embodiment 2

[0036] Embodiment 2, the purification device of the present embodiment also from figure 1 Seen in, it differs from Example 1 in that: the reaction tower 1 is also provided with a return pipe 9 communicated with the return device 6 and a circulating fly ash nozzle 1d, and the return device 6 is connected with the bag filter 4 and The fly ash outlet on the pre-dust collector 2 is connected. The fly ash captured in the purification process can be used as return ash to return to the reaction tower through the circulating fly ash nozzle 1d on the outlet end of the return pipe 9 for recycling. The return ash contains fly ash particles, residual neutralizer, and neutralizer, which together with the fly ash in the flue gas participate in the drying, catalysis, and chemical reactions in the tower, so that the utilization rate of the neutralizer can be maximized, and The reaction products in the flue gas, the circulating fly ash and the sprayed neutralizer increase the contact reaction...

Embodiment 3

[0037] Embodiment 3, the purification device of the present embodiment also from figure 1 It can be seen from the above that it is different from Embodiment 1 or Embodiment 2 in that: its return device 6 is also equipped with a return cage 6' that can adjust the outflow of the return material through a frequency converter and has an overflow ash Pipe 8 overflow cage 7. Thus, the purifying device of this embodiment can automatically adjust the frequency of the frequency converter on the return cage 6' according to the flue gas differential pressure and the flue gas flow rate in the reaction tower, and change the return amount of fly ash; and in the return feeder When the fly ash is redundant, it can be sent to the ash conveying device (not shown in the figure) provided outside through the overflow cage 7 and the overflow ash pipe 8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com